Q1. Which metal materials is the Upward Continuous Casting Machine generally suitable for?

A: CDOCAST Upward Continuous Casting Machine is primarily suitable for copper (pure copper, oxygen-free copper), copper alloys (such as brass, bronze), as well as low-melting-point metals like silver and gold (If your raw material is alloy, please inform us of the specific composition of the alloy during the inquiry so that we can check).

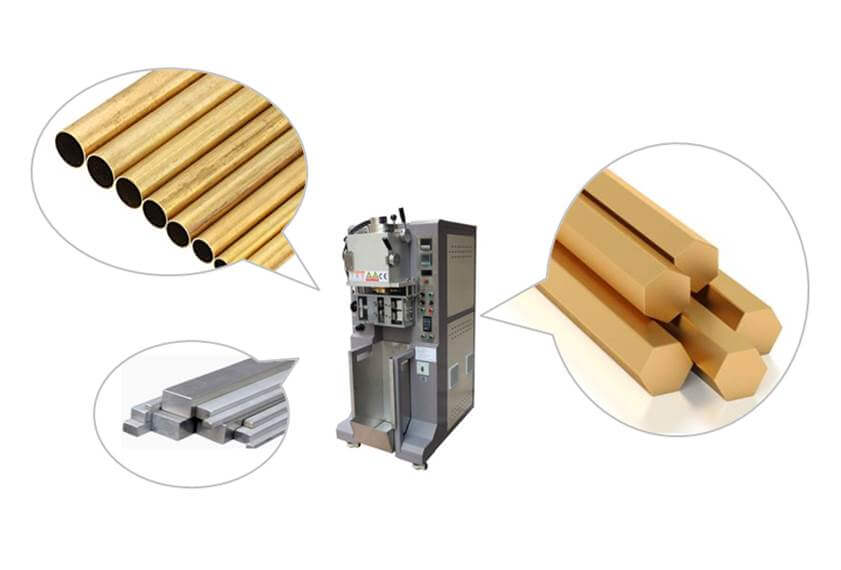

Q2. What products can be manufactured using the Upward Continuous Casting Machine?

A: Our Upward Continuous Casting Machine is ideal for producing wire, rods, bars, plates/strips, and tubes etc.

Q3. What is the typical dimensional range of products cast by your Upward Continuous Casting Machine?

A: The following are the size ranges that can be produced:

✔ Silver/Copper Bars: Diameter 6-30mm

✔ Silver/Copper Tubes: Max. OD 80mm, Wall Thickness 3mm; Min. OD 20mm, Wall Thickness 1-2mm (Production rate approx. 200mm/min)

✔ Silver/Copper Plates/Strips: Width 12-40mm, Thickness 6-12mm

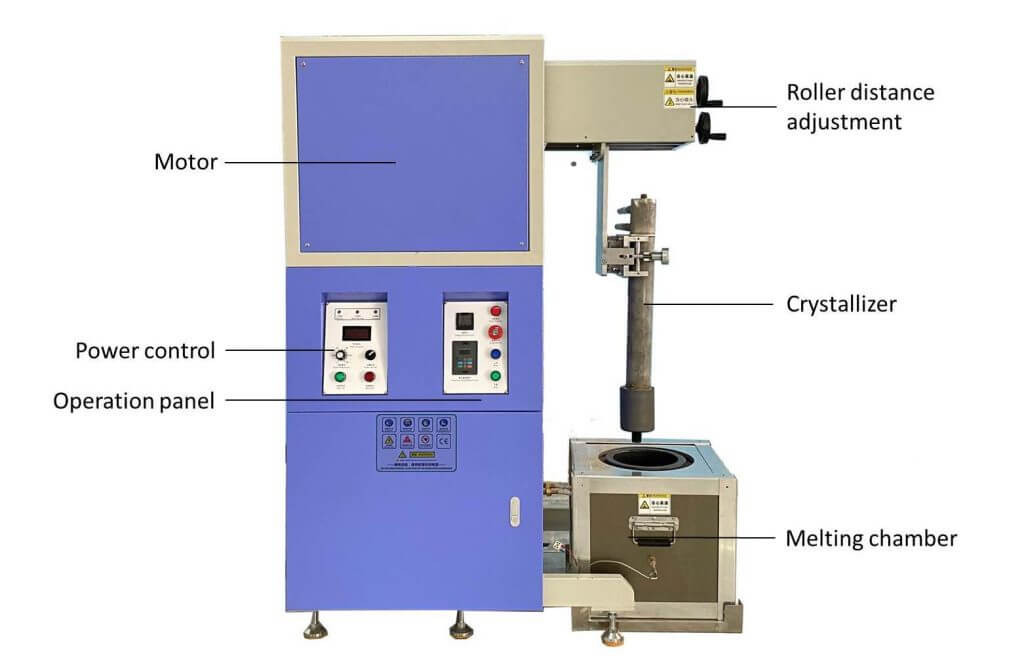

Q4. What is the working principle of the Upward Continuous Casting Machine?

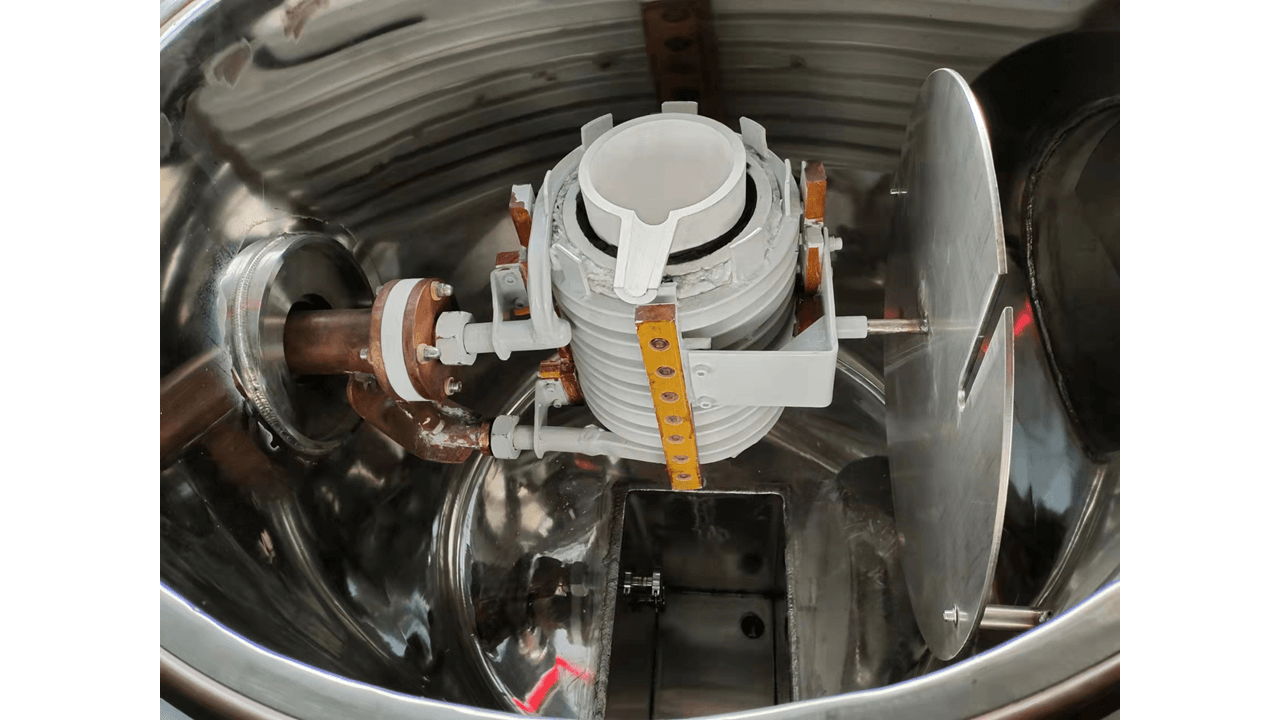

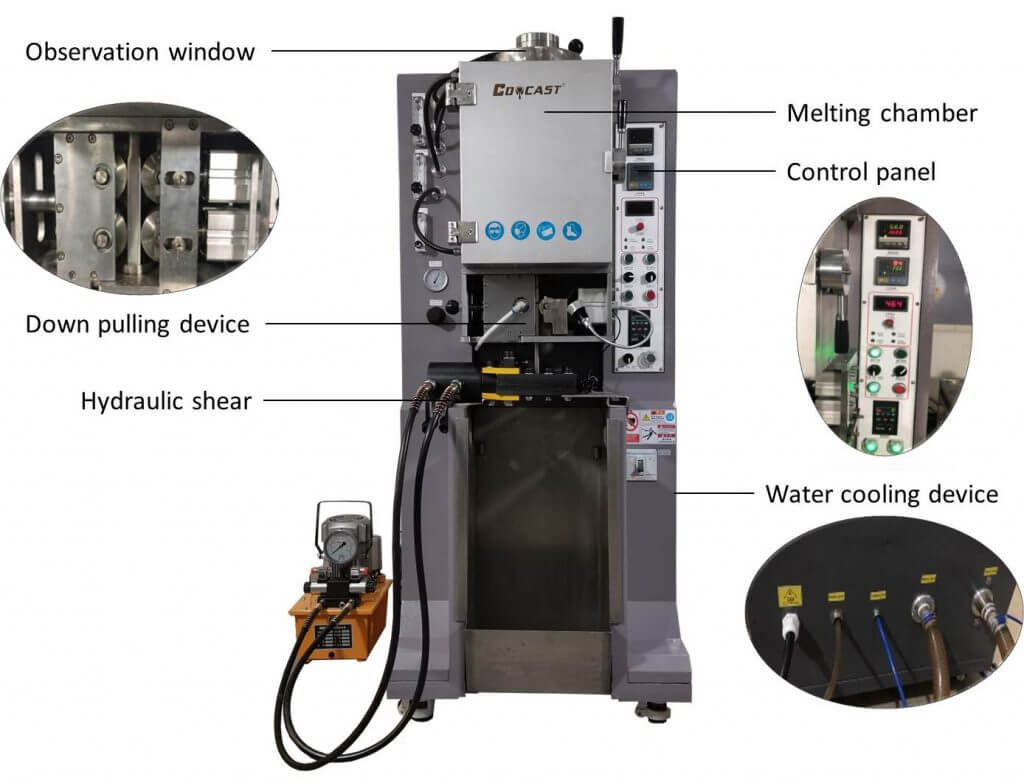

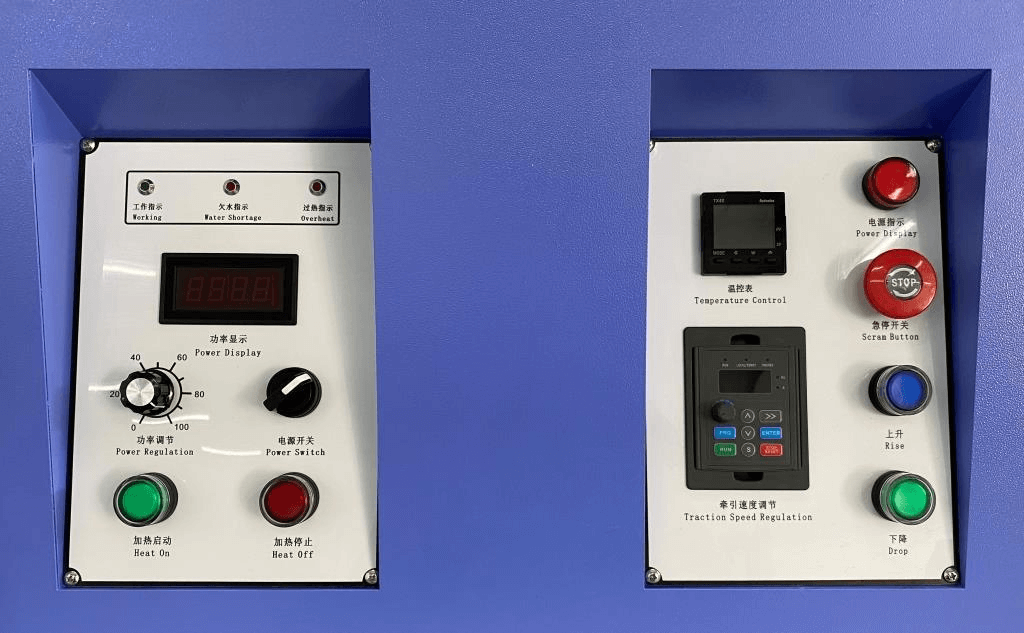

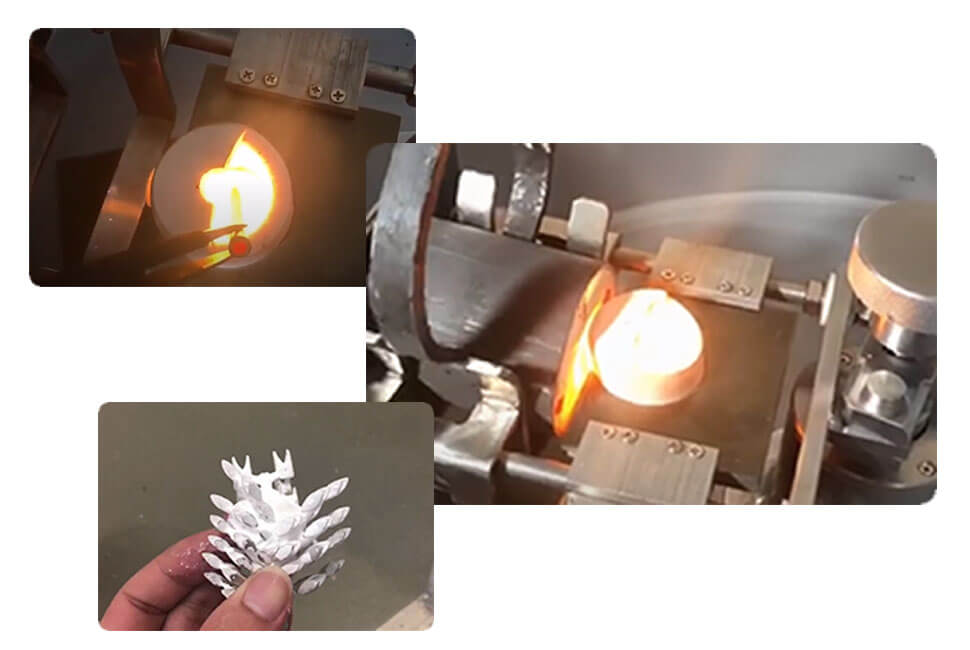

A: The core principle is “Upward Pulling, Reverse Solidification”. It utilizes a crystallizer for localized cooling within the molten metal bath. A pulling mechanism continuously draws the solidified metal upward from the melt, enabling a continuous or semi-continuous casting process.

Q5. How can metal oxidation be effectively minimized during casting?

A: The simplest and most effective method is to cover the surface of the molten copper with a layer of charcoal or graphite flakes. This creates a protective barrier, isolating the molten metal from direct contact with the furnace atmosphere.

Q6. What are the common consumables for the Upward Continuous Casting Machine, and what is their typical service life?

A: The main consumables include silicon carbide crucibles, graphite molds etc.

Silicon Carbide Graphite Crucible: Service life approximately 50-150 heats (based on copper melting).

Graphite Components: Service life approximately 1-2 tons (based on finished product output).

*The actual service life depends significantly on the customer’s specific casting parameters and routine maintenance practices.

Q7. How do I select the right Upward Continuous Casting Machine for my needs?

A: To provide an accurate recommendation and quotation, we need the following information:

1. What is your raw material: Pure copper? Brass? Or other?

2. What product do you want to cast: Copper bar? Copper tube? And what are its specific dimensions?

3. What is your daily output? And how many working hours per day?

We can offer Small Upward Casting Machine and large-scale Upward Continuous Casting Machine:

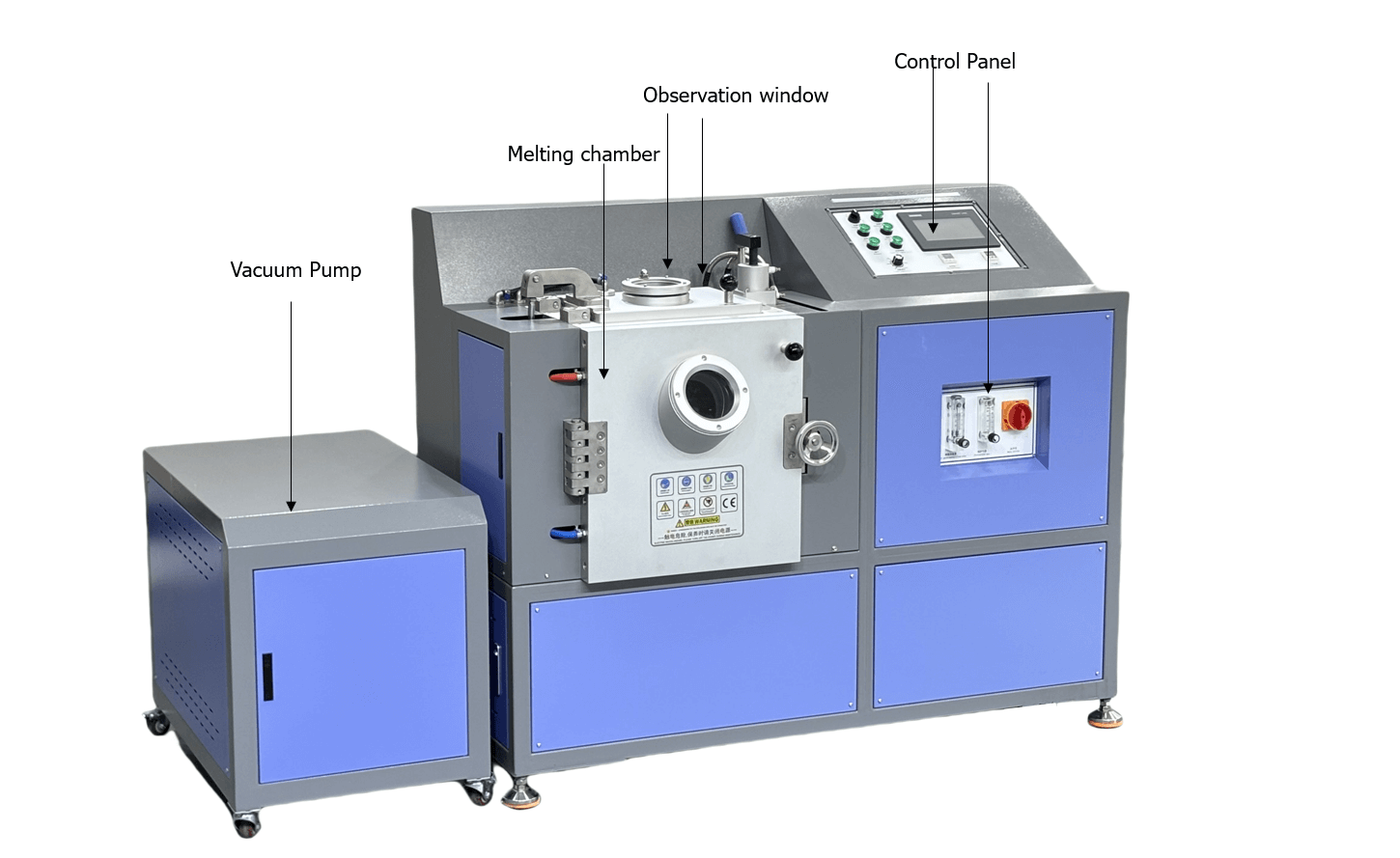

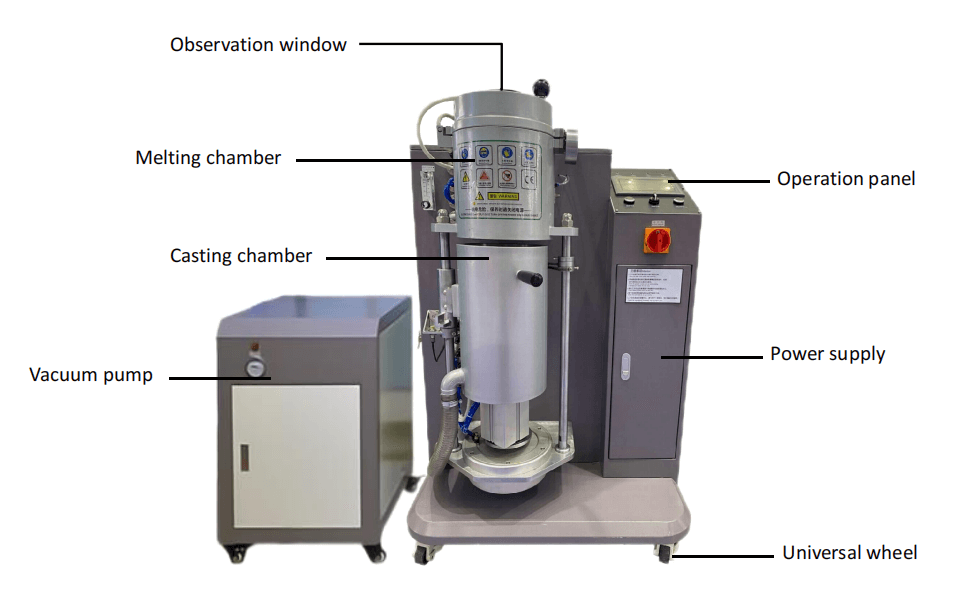

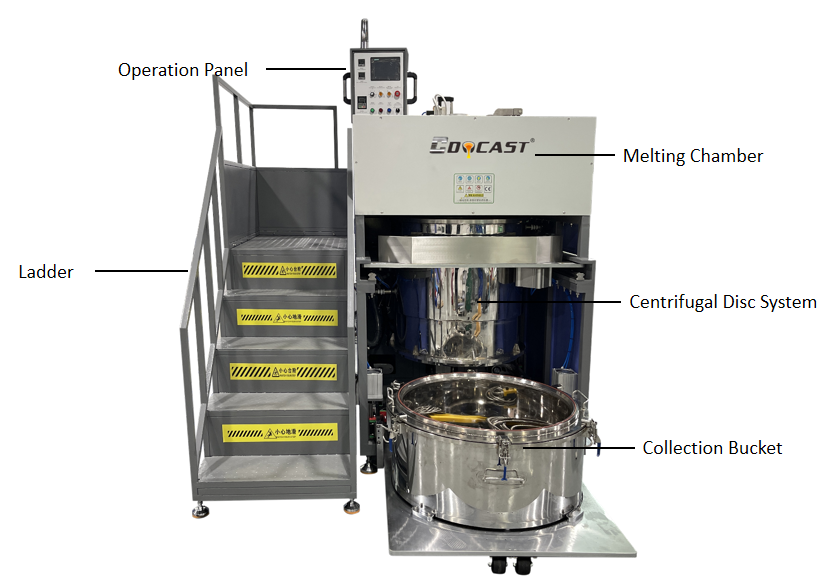

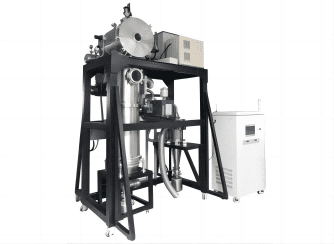

*[Small Upward Casting Machine]: Available in single or double-strand configurations, with a daily output of 1-2 tons. Features an integrated melting-and-casting design. Key advantages include a small footprint, simple structure, easy installation and operation, high flexibility, and the ability to start or stop the process conveniently.

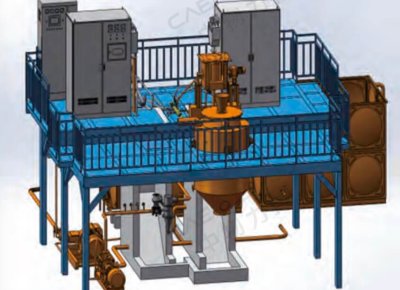

*[Large-Scale Upward Continuous Casting Machine]: Designed for high-volume production, requiring an annual output demand of at least 1000-2000 tons. Characterized by massive output, high automation, and exceptional efficiency. This system is designed for continuous 24/7 operation; interruptions can risk equipment damage. Once started, stable and uninterrupted operation is essential.

Q8. What are the main advantages of the Upward Continuous Casting Machine compared to other methods like Horizontal Continuous Casting?

A: The key advantages of our Upward Continuous Casting Machine include:

*Low Investment Cost: Relatively simple equipment structure, small footprint, resulting in lower initial investment and maintenance costs.

*High Flexibility: A single machine can simultaneously pull multiple strands (multi-strand casting). Simply changing the crystallizer allows production of different sizes and shapes (e.g., rods, wires, tubes).

*Superior Product Quality: Employs directional solidification, yielding a dense ingot structure with minimal porosity and slag inclusions. Especially suitable for producing high-quality oxygen-free copper products.

*Lower Energy Consumption: Compact process flow minimizes heat loss.

Q9. Why does the crystallizer require separate cooling during the upward casting process? What are the requirements for the cooling water?

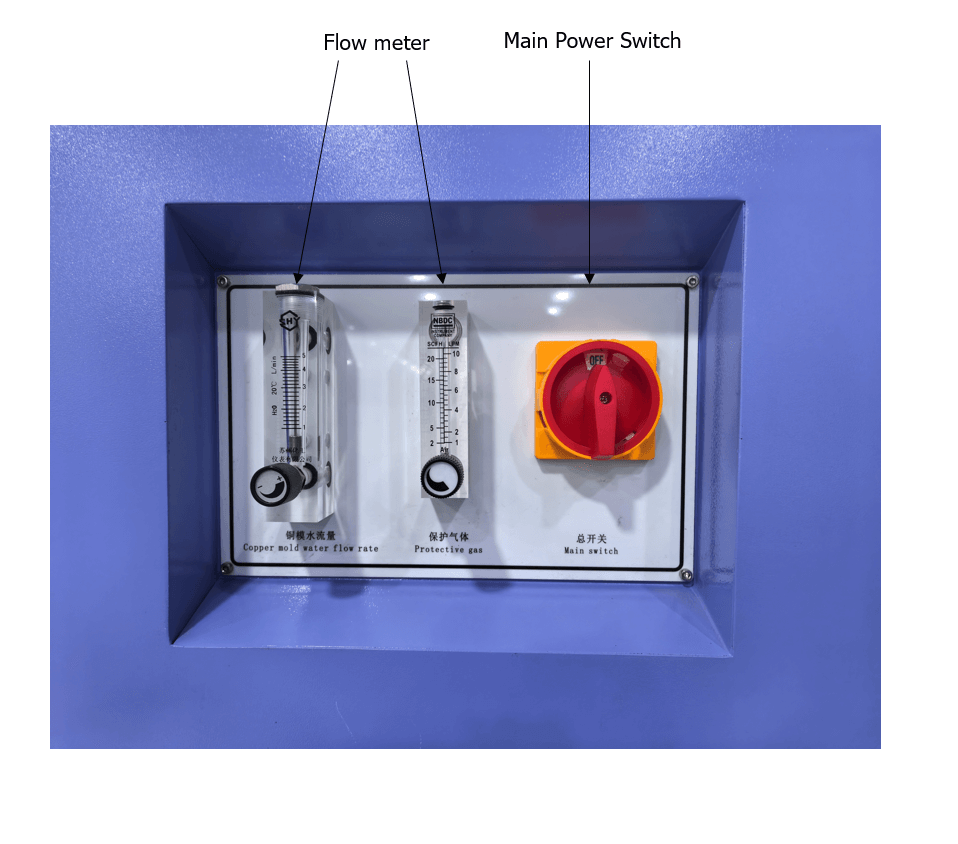

A: The cooling water’s role is to carry away the substantial heat absorbed by the crystallizer from the liquid metal, ensuring rapid and uniform solidification within the crystallizer. Separate cooling allows for precise regulation of water flow and temperature, controlling the solidification process and guaranteeing optimal casting results.

Cooling Water Quality: The cooling water must be clean, free of impurities, and of moderate hardness. Impurities and scale can deposit inside the crystallizer’s water jacket, severely impairing cooling efficiency, leading to poor surface quality or even breakouts (liquid leakage). Using softened or deionized water is highly recommended.

Water Temperature & Pressure: The optimal water temperature should be maintained between 35-50°C and adjusted based on specific conditions. Water pressure should be within the range of 0.2 – 0.4 MPa.

Q10. Are the “Casting Speed” and “Cooling Intensity” adjustable on the Upward Continuous Casting Machine? How do they affect product quality?

A: Yes, the casting speed and cooling temperature are all adjustable. The maximum casting speed is typically adjustable between 1000-1200 mm/min (based on φ8mm rod) and must be fine-tuned according to the specific product dimensions. Generally, larger product sizes require slower casting speeds.

*Excessively Fast Casting Speed: Can lead to incomplete solidification of the strand within the crystallizer, causing “breakout” accidents, or resulting in internal issues like a porous structure or shrinkage cavities.

*Excessively Slow Casting Speed: Increases friction between the strand and the crystallizer wall, potentially breaking the strand, and reduces production efficiency.

*Insufficient Cooling Intensity: Results in a thin solidified shell and coarse internal grains, increasing the risk of breakouts.

*Excessive Cooling Intensity: Creates a large temperature gradient and high thermal stress within the strand, potentially leading to surface cracks.

Therefore, optimizing the match between pulling speed and cooling intensity based on the specific product specifications and metal type is crucial.

Q11. What safety precautions should be observed during the operation and maintenance of the Upward Continuous Casting Machine?

A: Prevent Burns: The operating area involves high temperatures. Always wear appropriate protective clothing, gloves, and a face shield.

Prevent Electric Shock: Ensure all electrical equipment is properly grounded. Prevent cooling water leaks onto electrical components.

Prevent Molten Metal Splashes: Contact between molten metal in the crucible and water can cause violent splashing. Keep the work area and tools completely dry.

Regular Maintenance: Conduct periodic inspections for wear on the crystallizer, crucible, and graphite components. Regularly clean cooling water passages and tighten mechanical parts to ensure stable equipment operation and safe production.

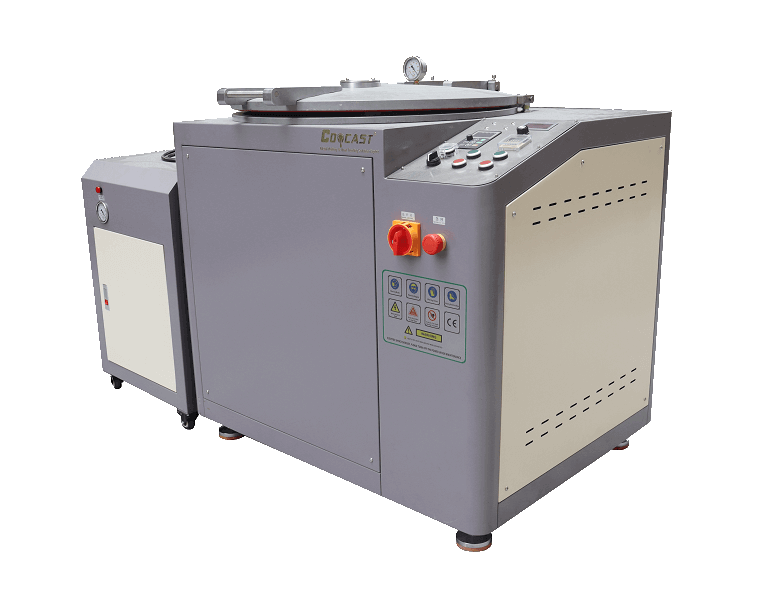

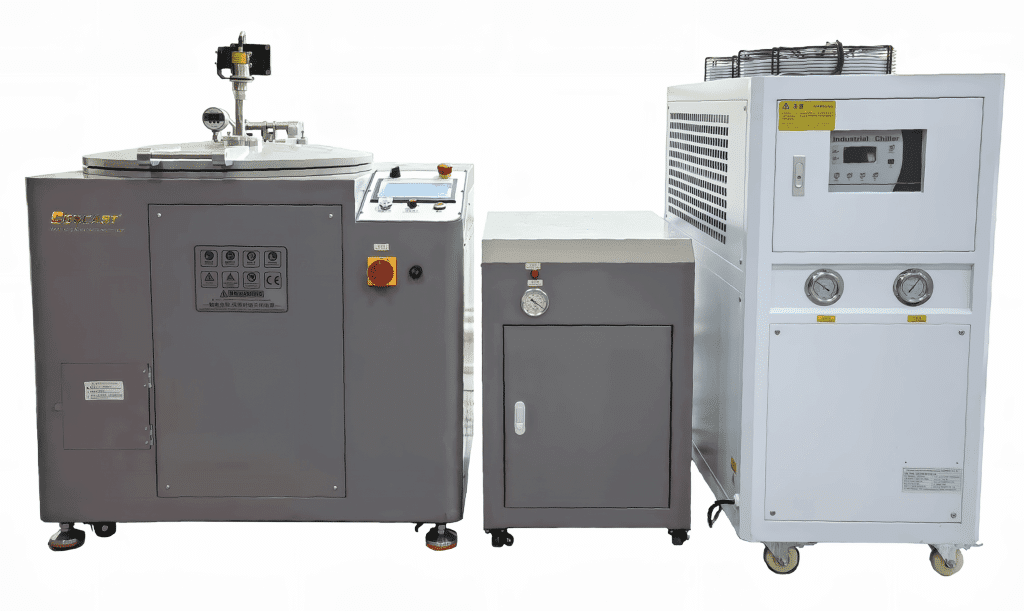

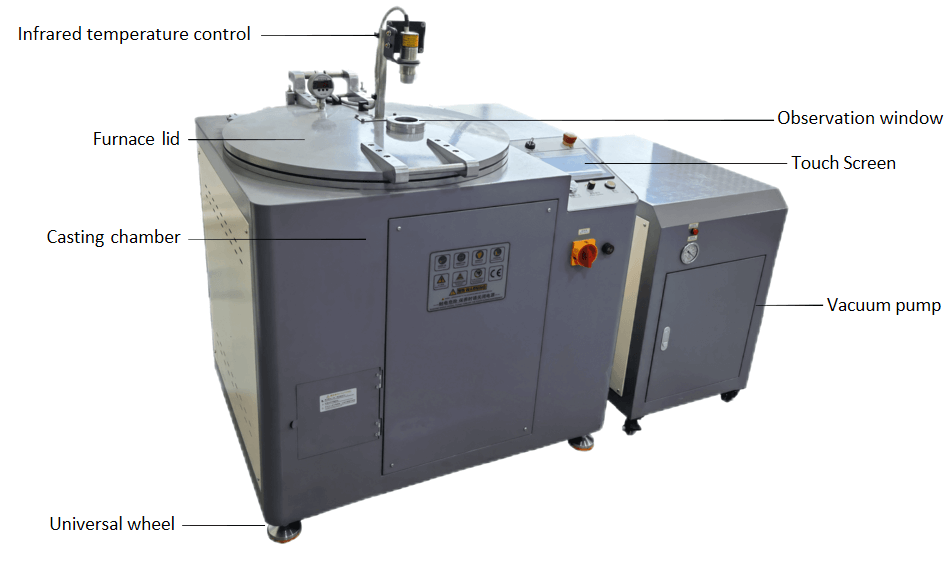

10KG 20KG Vacuum Induction Melting Furnace

10KG 20KG Vacuum Induction Melting Furnace

To learn all equipment in jewelry casting line

To learn all equipment in jewelry casting line

The parameter of vacuum gypsum mixer

The parameter of vacuum gypsum mixer

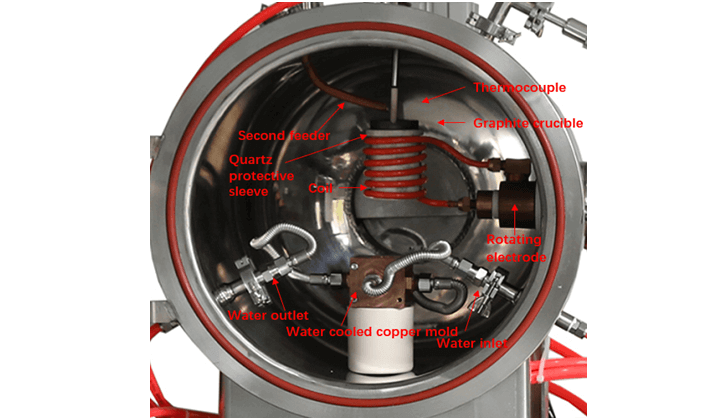

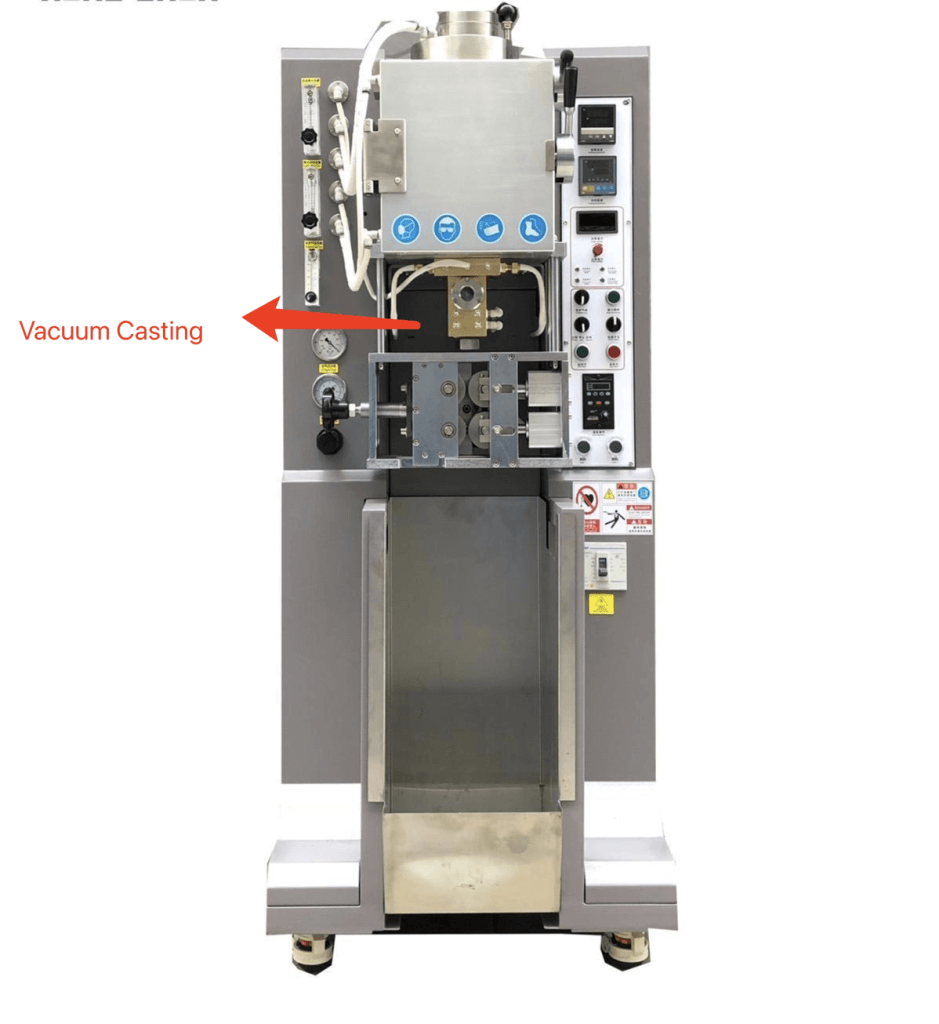

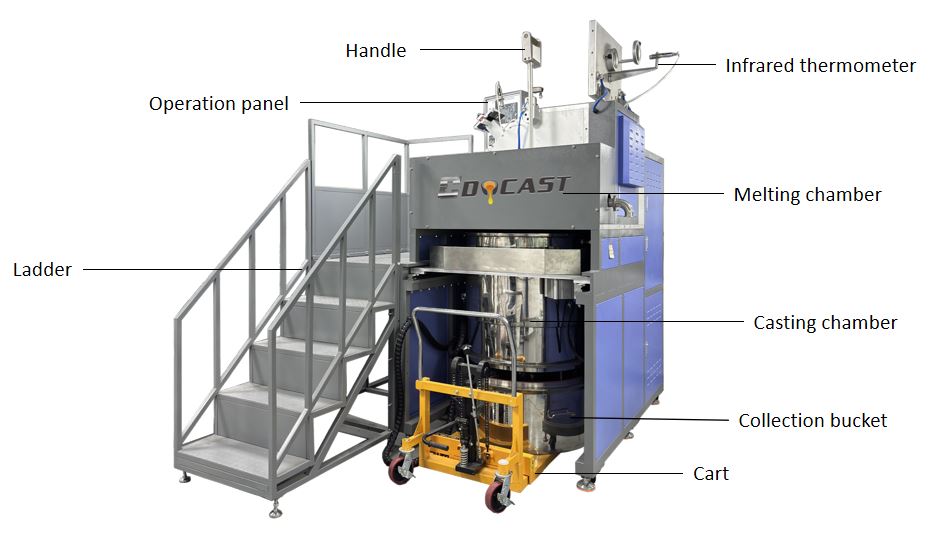

Vacuum Continuous Casting Machine For K-GOLD, Metal Alloy

Vacuum Continuous Casting Machine For K-GOLD, Metal Alloy

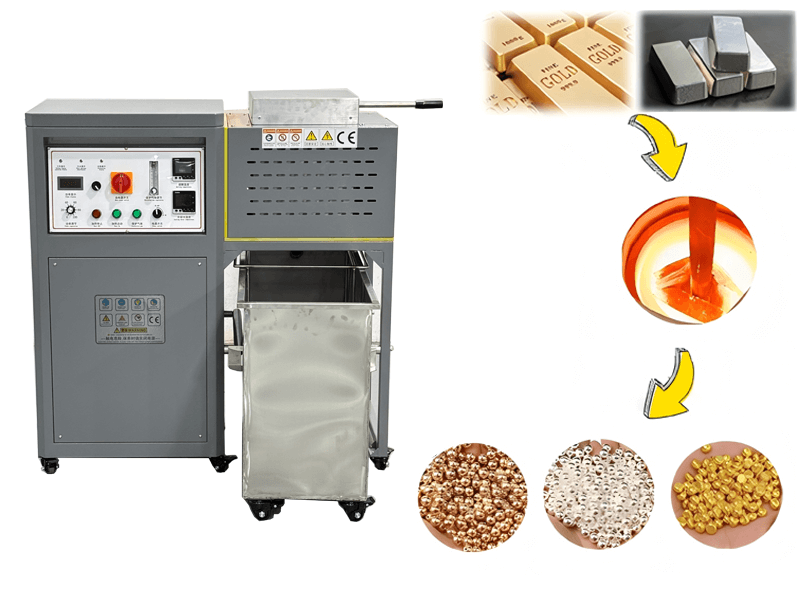

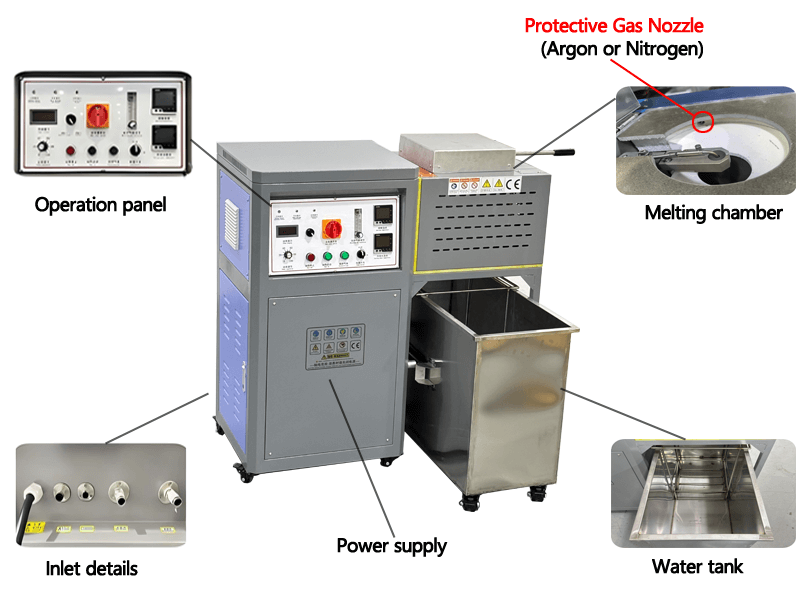

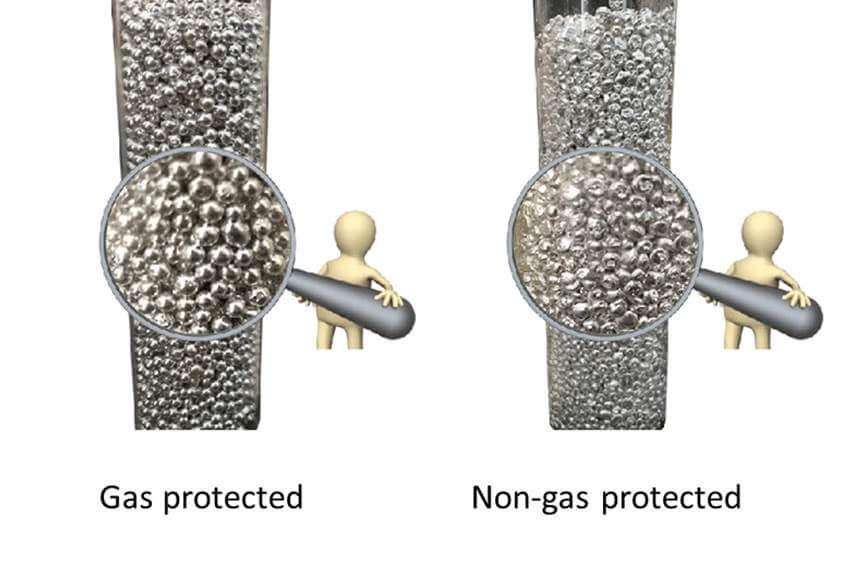

20-50kg Metal Granulating Machine with Stirring Function

20-50kg Metal Granulating Machine with Stirring Function

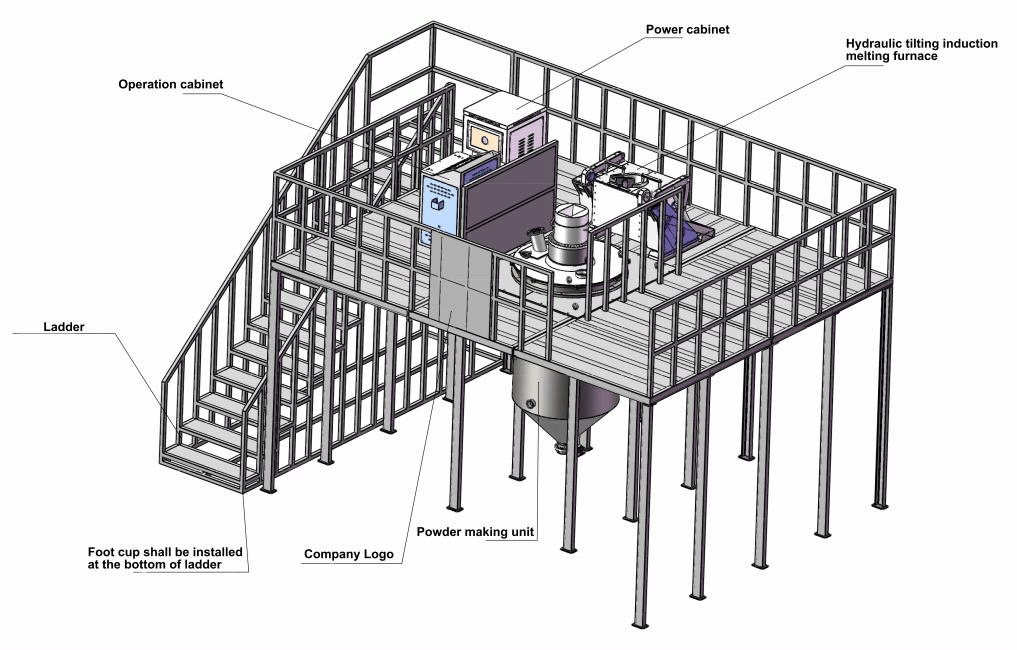

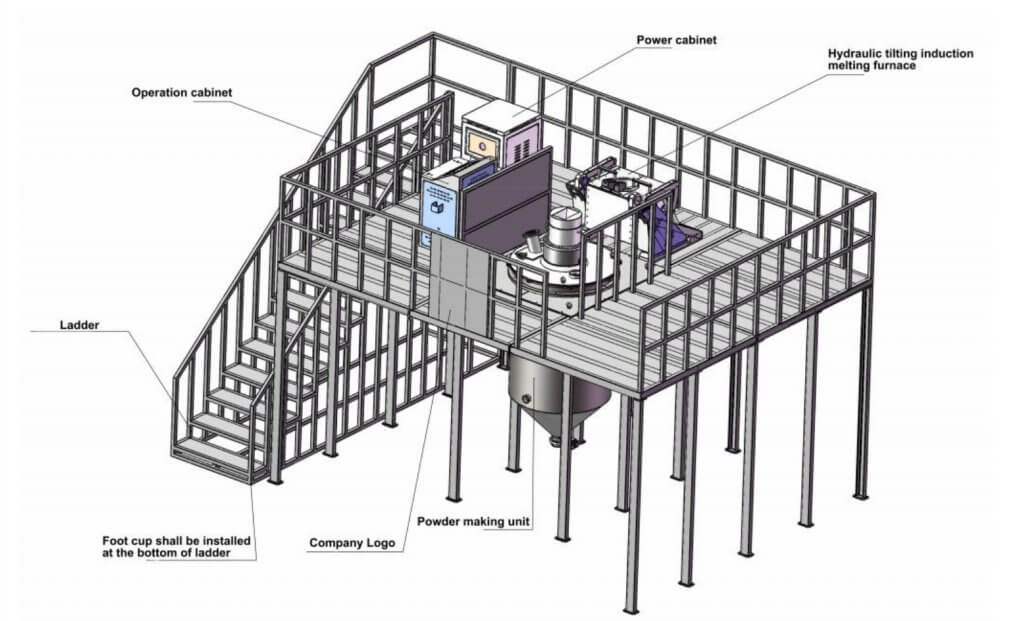

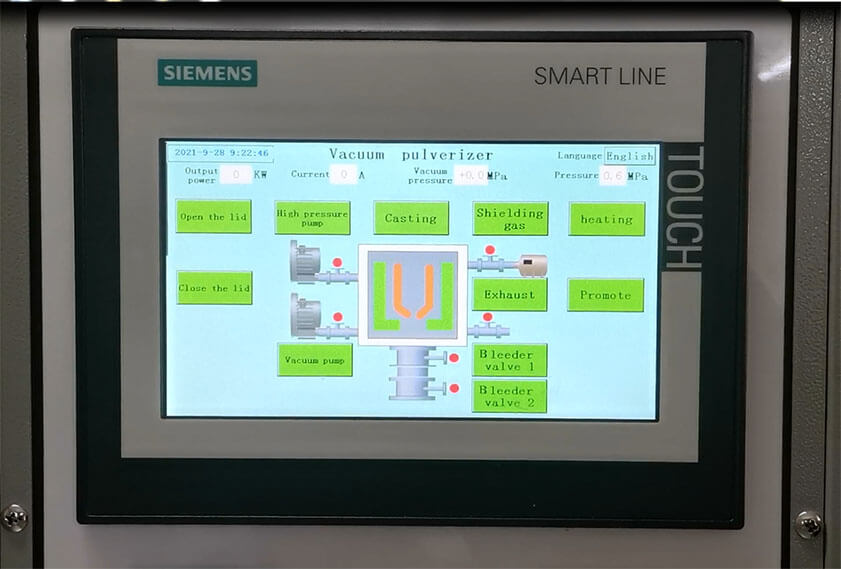

10kg 20kg 30kg 50kg Metal Vacuum Powder Making Machine

10kg 20kg 30kg 50kg Metal Vacuum Powder Making Machine

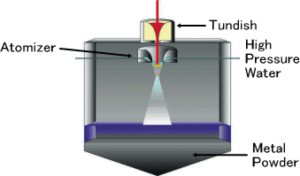

Gas Atomization Vacuum Powder Making Machine

Gas Atomization Vacuum Powder Making Machine