- Call Us: 008615168765707

- Mail Us: [email protected]

Customized Graphite Crucible &Graphite Mould For the Melting & Casting Machine

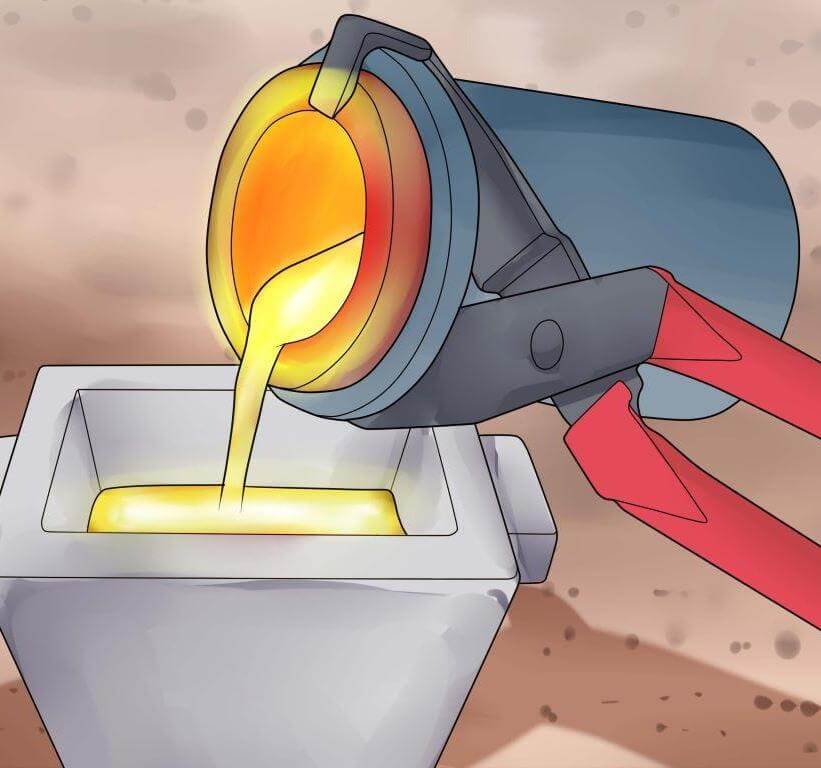

Graphite mould is widely used in various precision casting. It has the advantages of high temperature resistance, high machining accuracy, uniform temperature distribution and easy demoulding. Graphite mould will be used in more fields. It is used for casting precious metals (gold, silver, etc.).

Application.

1. Brass casting mould.

2. Red copper continuous casting mould.

3. Continuous casting mould for gold, silver and platinum jewelry.

According to the shape of casting products, it can be divided into round bar mold, hollow tube mold and special-shaped mold.

| Description | Size(mm) | |||||

| L1 | W1 | H1 | L2 | W2 | H2 | |

| 100g | 55 | 40 | 20 | 35 | 20 | 10 |

| 200g | 70 | 45 | 20 | 50 | 25 | 10 |

| 250g | 67 | 50 | 26 | 47 | 25 | 16 |

| 300g | 70 | 57 | 20 | 50 | 37 | 10 |

| 400g | 75 | 67 | 20 | 50 | 47 | 10 |

| 500g | 70 | 67 | 26 | 50 | 47 | 16 |

| 1kg | 135 | 42 | 32 | 115 | 22 | 22 |

| 2kg | 160 | 48 | 38 | 140 | 28 | 28 |

| 3kg | 175 | 52 | 42 | 155 | 32 | 32 |

* The mould can be customized to desired shape

1. Thermal stability. According to the use conditions of graphite crucible, we will specially design the production procedure to ensure the reliability of product quality.

2. Corrosion resistance: according to the use conditions of graphite crucible for quenching and heating, we will specially design production procedures to ensure the reliability of product quality. Uniform and fine basic design can delay the corrosion of crucible.

3. Impact resistance: the basic design of graphite crucible is uniform and fine, which can delay the corrosion of crucible. Graphite crucible can withstand high thermal shock, so any process can be carried out.

4. Acid resistance: graphite crucible can withstand high thermal shock, so any process can be carried out. The addition of special materials will greatly improve the quality of crucible, especially the acid resistance index, and prolong the service life of graphite crucible.

5. High thermal conductivity: high content of fixed carbon ensures good thermal conductivity of crucible. High content of fixed carbon ensures good thermal conductivity, shortens dissolution time and significantly reduces energy consumption.

6. Control metal pollution. Strictly control the material composition to ensure that the graphite crucible will not pollute the metal during dissolution.

7. The quality is stable. High pressure molding technology and quality assurance system will fully ensure the stability of quality.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Graphite Crucible &Graphite Mould

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the costs associated of gold melting furnaces

CDOCAST provide you types of Electric Melting Furnace for you to choose when you want to invest in the furnace

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering ...

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal