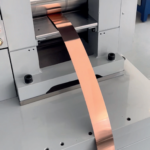

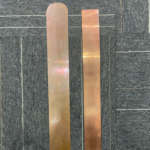

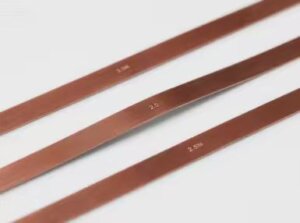

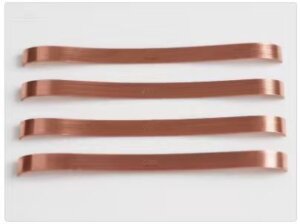

1Finished Products1

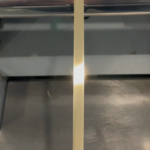

1Product Details1

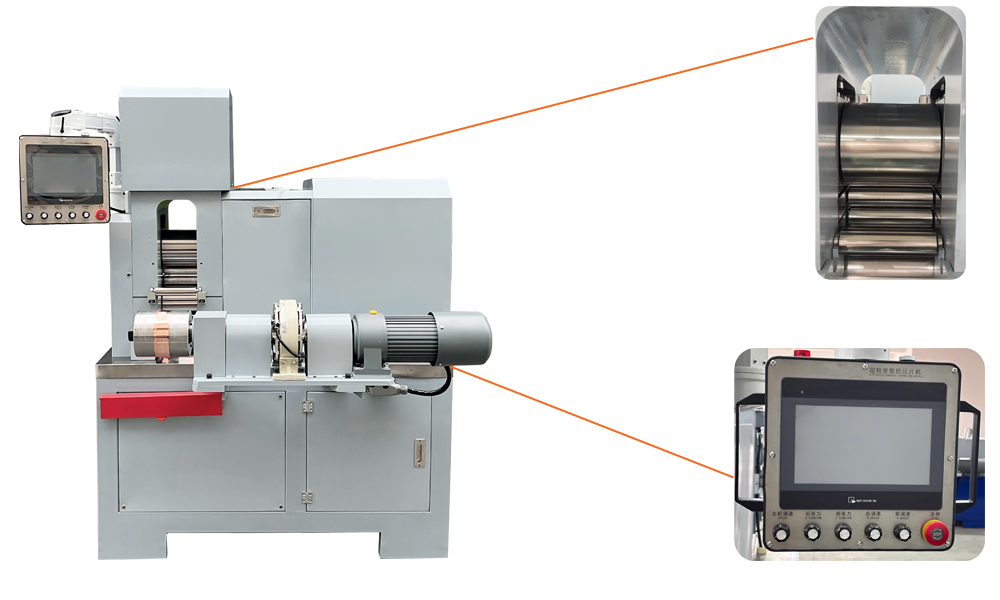

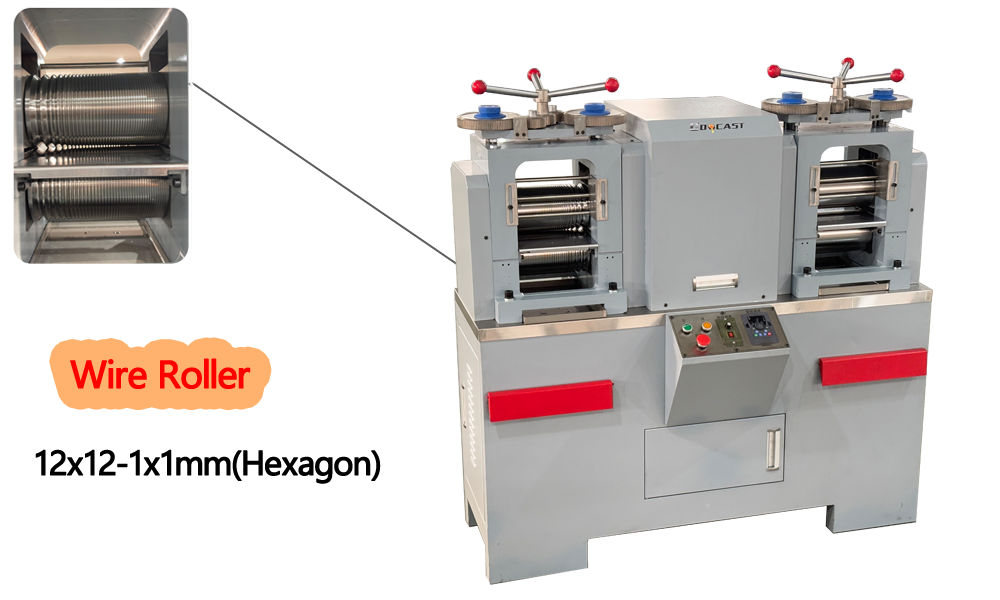

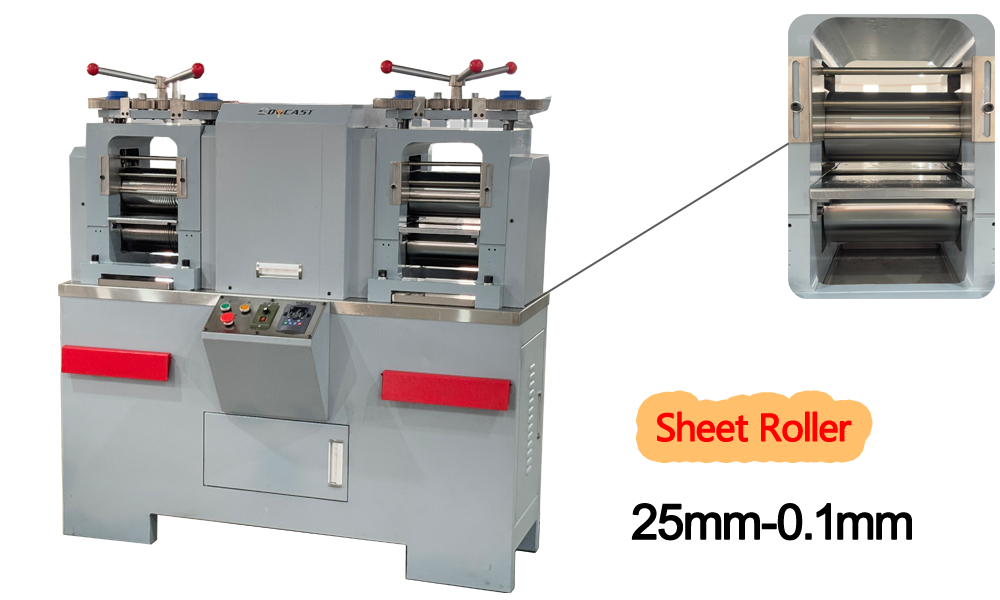

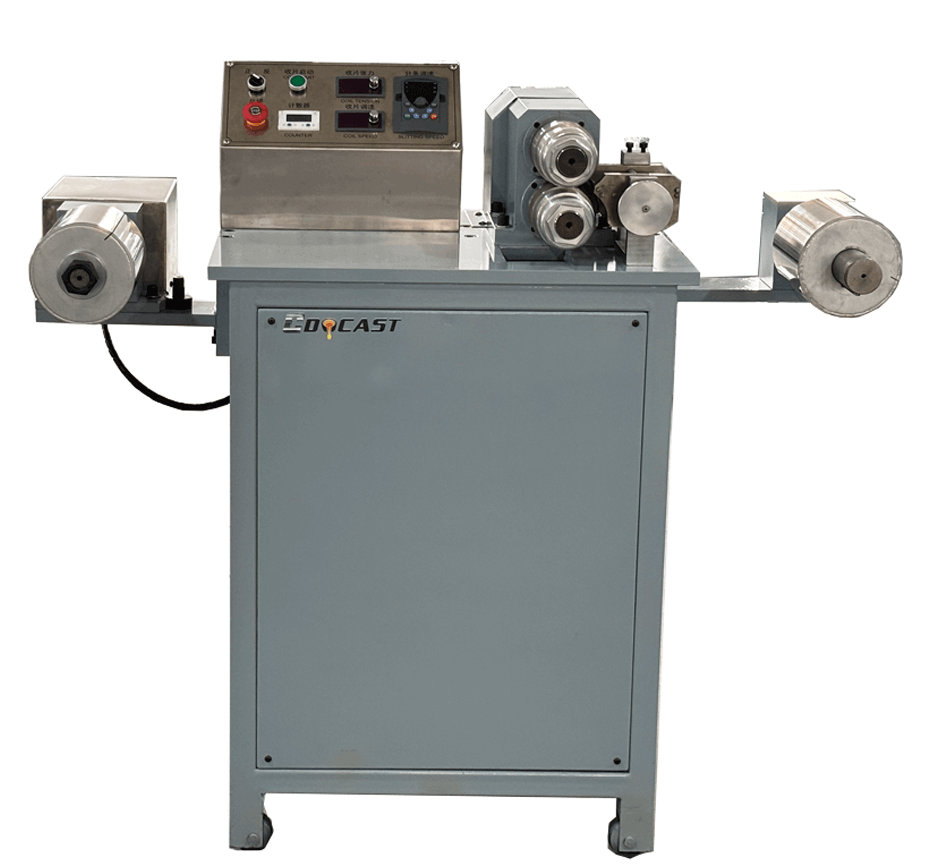

CNC Controlled 4-Roller Precision Rolling Machine

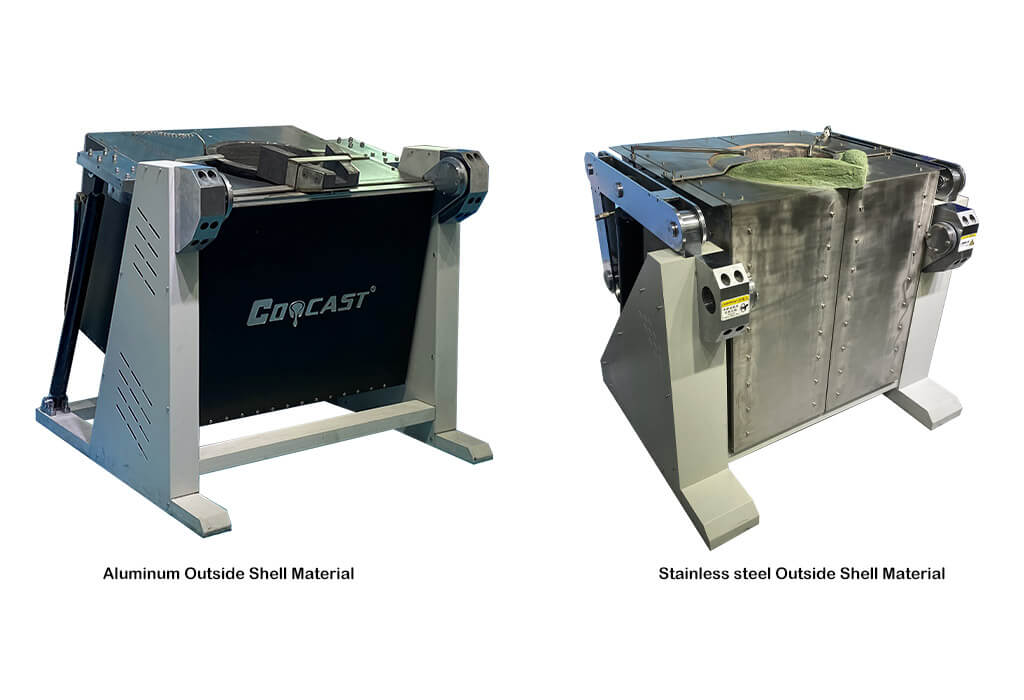

CDOCAST 4-Roller Precision Rolling Machine is suitable for rolling various gold, silver, copper, and aluminium bar plates. The mill adopts an advanced four-roll structure, comprising five core systems:

1. High-Strength Frame

2. Precision Roll System:

3. High-Efficiency Drive

4. Smart Hydraulic System

5. CNC System

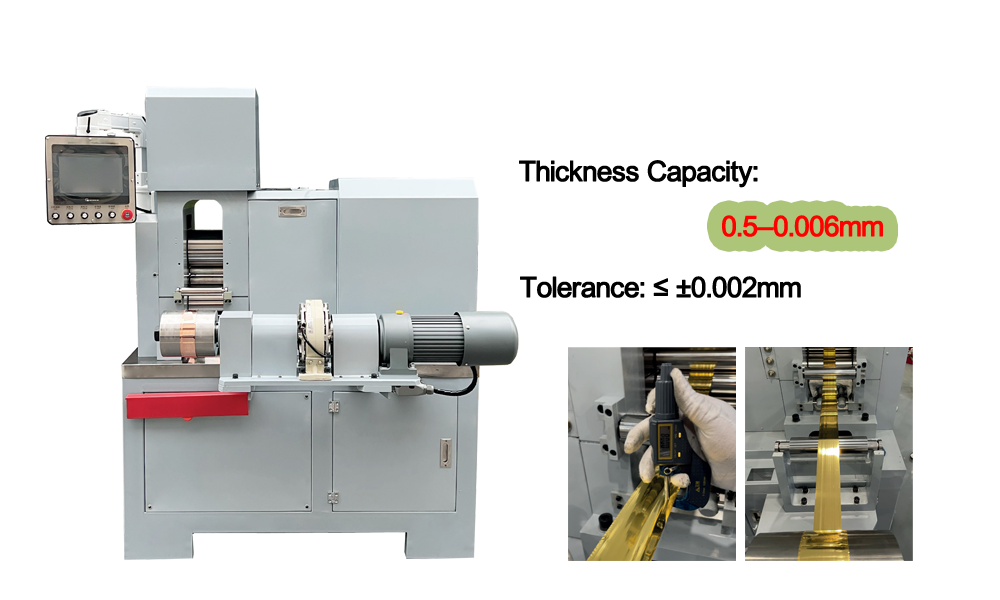

The 15HP ultra-precision CNC four-roll rolling mill features advanced four-roll technology, utilising a dual-roll system comprising Cr12MoV backup rolls and DC53 work rolls. It can precisely roll a 60mm-wide, 0.5mm-thick copper strip down to an ultra-thin 0.006mm, with thickness tolerance within ±0.002mm. Equipped with an automatic coiling/uncoiling system, it enables continuous rolling production without downtime due to material changes. The rolled metal strips exhibit smooth surfaces and burr-free edges, perfectly meeting the production requirements of high-precision electronic components and precision instruments.

This machine is particularly suitable for ultra-thin rolling of precious metals, copper alloys, aluminium alloys, and other materials. Its CNC system allows precise adjustment of rolling parameters to ensure uniform thickness. With a high-rigidity frame and optimized roll system design, it not only improves rolling accuracy but also significantly extends roll service life, making it an ideal choice for efficient precision production in industries such as new energy and electronic components.

Machine Details

4-Roll CNC Rolling Mill for Ultra-Thin Materials

Parameter

| Model | CDO-RMN7.5 | CDO-RMN10 | CDO-RMN15 | CDO-RMN20 |

| Motor | 5.5kW | 7.5kW | 11kW | 15kW |

| Voltage | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz |

| Servo Lift | 0.85kW | 0.85kW | 1.8kW | 1.8kW |

| Roller Speed | 11.4m/min | 13.1m/min | 20m/min | 13.4m/min |

| Output Thickness | 25-0.1mm | 30-0.1mm | 0.5-0.006mm (60mm Width Copper Strip) |

45-0.15mm |

| Output Tolerance | ≤±0.002mm | |||

| Roller Material | Cr12MoV | Cr12MoV | Working Roller: DC53 Supporting Roller: Cr12MoV |

Cr12MoV |

| Roller Hardness | HRC 60-62 | HRC 60-62 | DC53: HRC 60-63 Cr12MoV: HRC 60-62 |

HRC 60-62 |

| Roller Size | Ф 132x180mm | Ф 151x180mm Ф 151x250mm |

Working Roller: Ф 52x200mm Supporting Roller: Ф200x200mm |

Ф200x250mm |

| Lubrication System | Bearing Bush Grease Lubricated |

Bearing Bush Grease Lubricated |

Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated |

| Addition | Magnetic Powder Clutch Coiler |

Magnetic Powder Clutch Coiler | Magnetic Powder Clutch Coiler | Magnetic Powder Clutch Coiler |

| Weight | 1300kg | 1800kg | 2300kg | 3300kg |

| Size(LxWxH) | 1420x1350x1600mm | 1430x1350x1650mm | 1570x1170x1820mm | 1740x1500x1900mm |

| Magnetic Powder Coiler |

10kg( Optional) | 10kg( Optional) | 10kg( Optional) | 10kg/20kg( Optional) |

| Winding Motor | 10kg:2.2kW | 10kg:2.2kW | 10kg:2.2kW | 10kg:2.2kW 20kg:3.7kW |

Feature

CNC Controlled 4-Roller Precision Rolling Machine Feature:

- Stable Structure – High-strength frame ensures reliable rolling performance

- CNC Precision – Full digital control for accurate parameter adjustment

- Ultra-Thin Rolling – Capable of micron-level thickness (e.g., 0.006mm)

- Precision Roll System – Cr12MoV backup rolls + DC53 work rolls for durability

- Continuous Operation – Auto coiling/uncoiling for non-stop production

- High Accuracy – Thickness tolerance ≤±0.002mm, smooth & burr-free surface

- High Efficiency – Automated for mass precision manufacturing

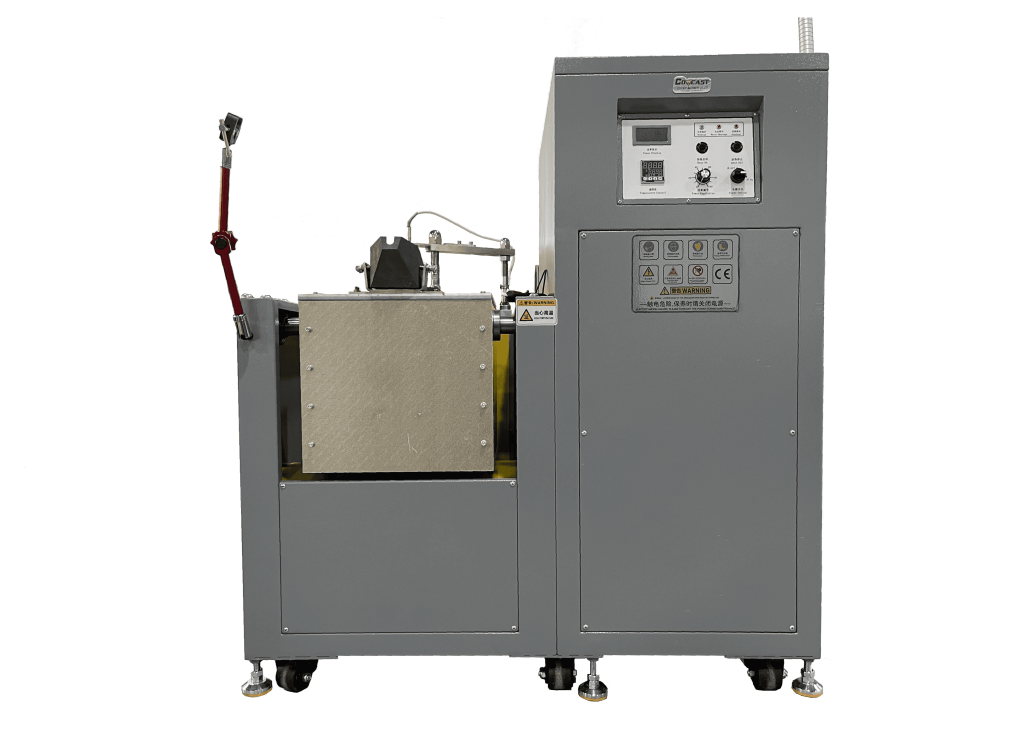

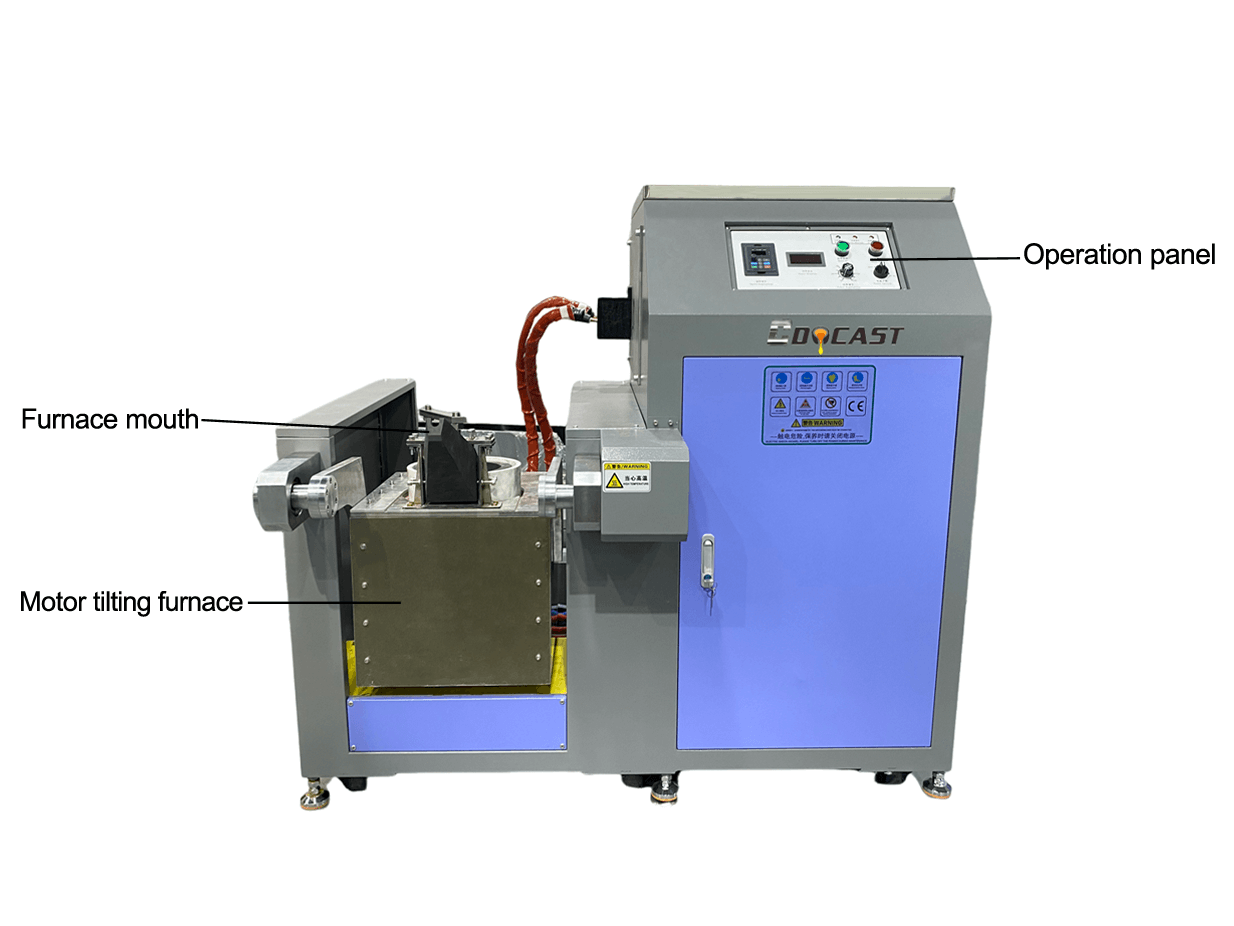

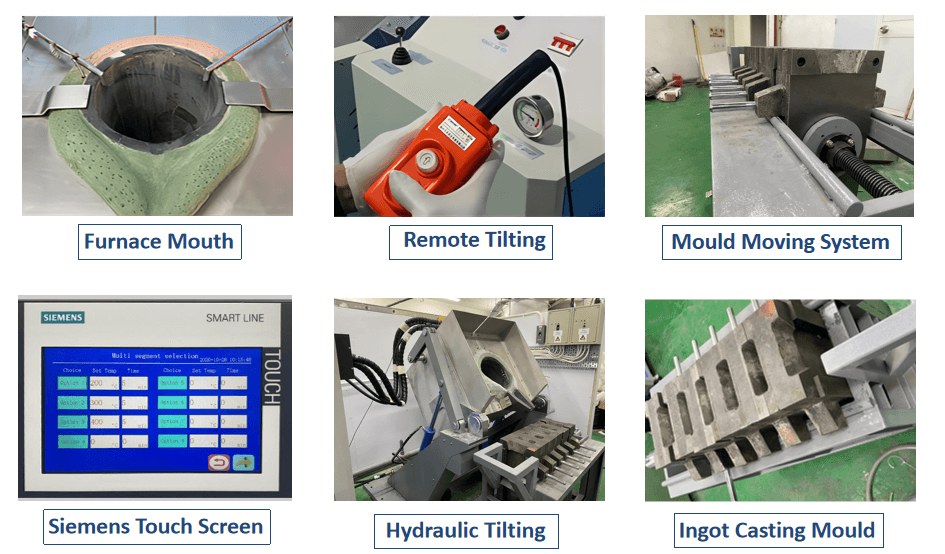

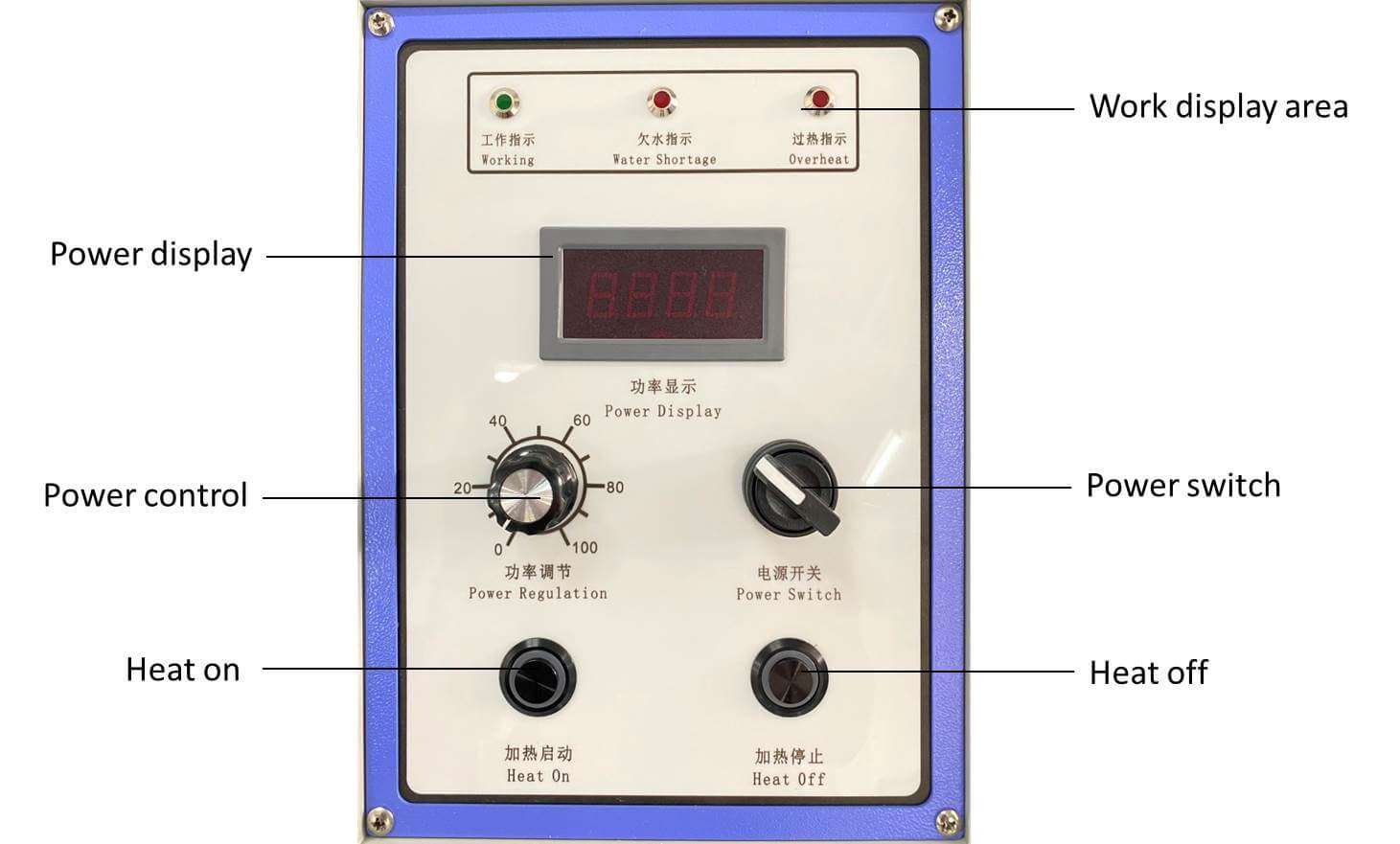

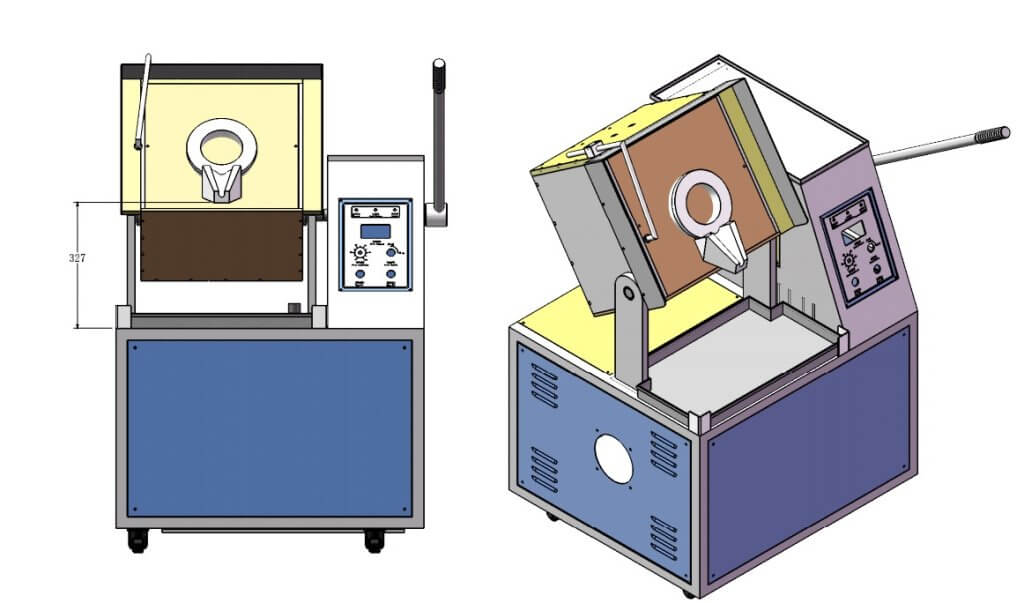

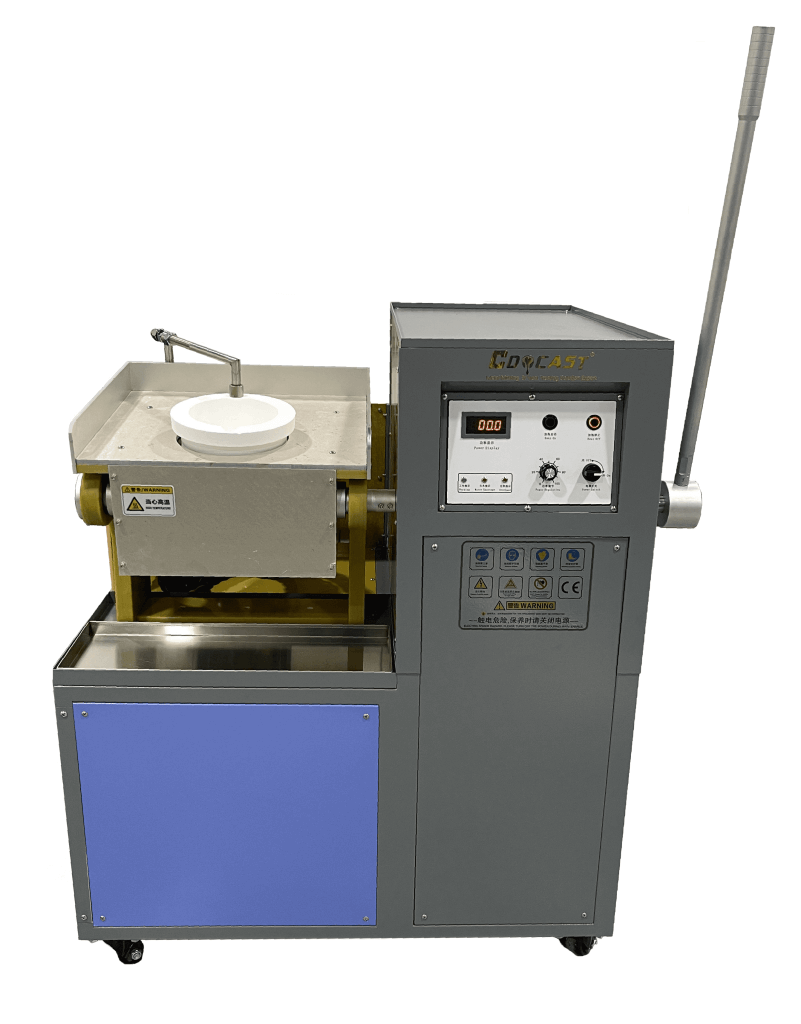

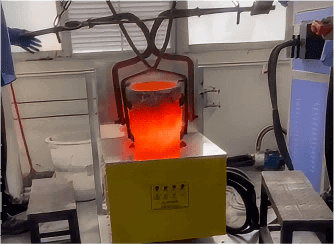

Silver Melting Furnace Details:

Silver Melting Furnace Details: