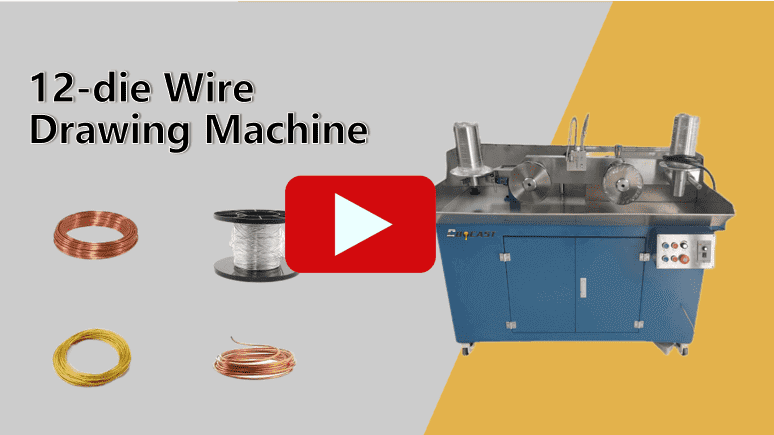

12-die Wire Drawing Machine

12-die Wire Drawing Machine

2.Structure

1.Wire release device

The reel for storing the original thick wire releases the wire smoothly through tension control.

2.Wire drawing die set

– 12 carbide or diamond dies (die holes), arranged in order from large to small according to the hole diameter.

– The compression rate (diameter reduction) of each die needs to be precisely designed, usually 10%-20%.

3.Drawing reel

– A power reel is configured behind each die to provide tensile force through rotation.

– The surface of the reel has grooves or coatings to prevent the wire from slipping.

4.Lubrication system

The circulation pump delivers lubricant to the contact surface between the die and the wire to reduce friction loss.

5.Wire take-up device

The stretched thin wire is rewound into a reel, and the take-up speed is synchronized with the drawing speed.

3.Process

1.Pay-off: The thick wire is drawn out from the pay-off reel and enters the first die through the guide wheel.

2.Step-by-step stretching:

– The wire passes through 12 dies in sequence, and the diameter of each die decreases and the length increases.

– After each stretching, the wire is pulled by the corresponding reel and accumulates tension.

3.Lubrication and cooling: Spray lubricant throughout the process and dissipate heat at the same time.

4.Winding: The final thin wire is wound by the take-up reel to complete the processing.

4.Technical Features

– Efficient production: 12 continuous stretching, one-time forming, suitable for large-scale fine wire manufacturing.

– Precision control: The mold aperture tolerance is small (±0.001mm) to ensure uniform wire diameter.

– Energy-saving design: Multi-stage transmission optimizes energy consumption, and some models are equipped with variable frequency speed regulation.

– Applicable materials: copper, aluminum, stainless steel, alloy and other metal wires.

5.Application Areas

– Wires and cables: wire drawing of copper and aluminum wires.

– Metal products: processing of steel wire ropes, spring wires, and welding wires.

– Precision industry: preparation of electronic component leads and ultra-fine metal wires.

Through multi-stage stretching and precision control, the 12-die wire drawing machine can efficiently and stably process coarse metal wires into high-precision fine wires, and is one of the core equipment in the metal wire manufacturing industry.

Please contact us if you are interested!

+86-15168765707

Email: [email protected]

Website: www.cdocast.com