- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the most economical platinum melting furnace in china

In the field of precious metal metallurgy, platinum Melting furnaces are considered an efficient and precise tool for melting and refining precious metals such as platinum, gold, silver, etc. This advanced metallurgical equipment combines medium-frequency induction heating technology and precision control systems, bringing revolutionary changes to the precious metal processing industry.

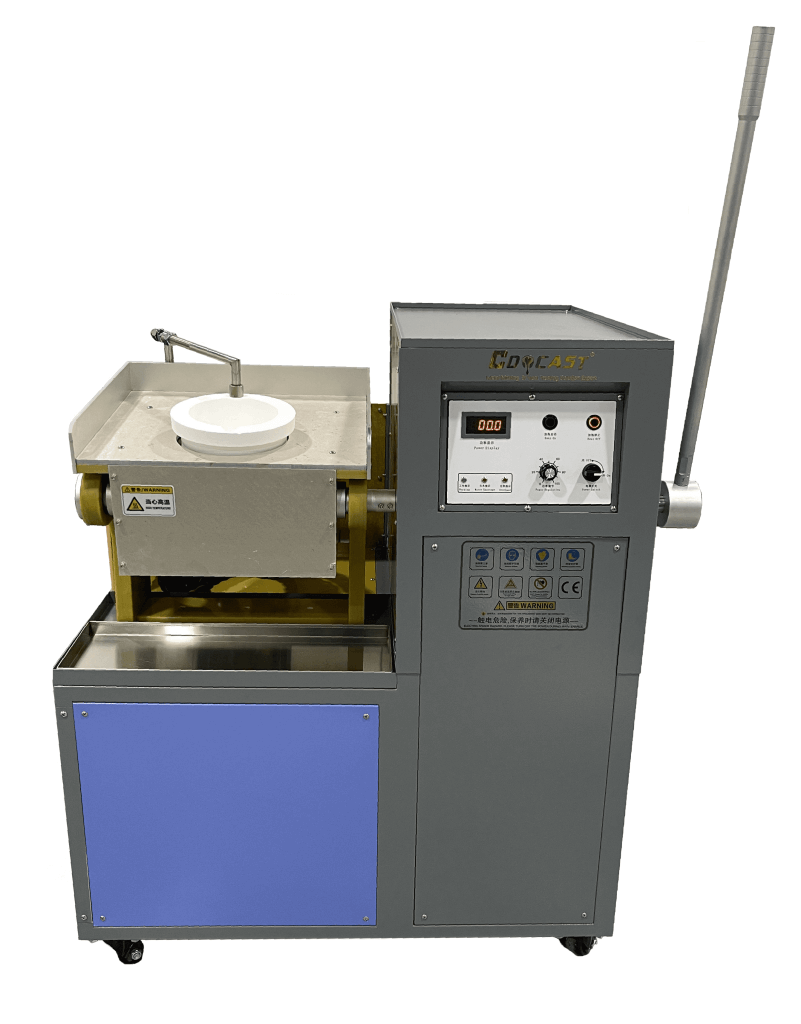

CDOCAST platinum melting furnace is specially designed for the small amount melting of platinum and palladium as well as high-temperature metals such as steel and stainless steel in quartz crucibles with capacities from 1kg to 15kg.

Is an extremely versatile induction melter in order to meet a wide range of needs. This platinum melting furnace is specially designed on the IGBT induction technology.

CDOCAST platinum melting machines are designed to be sourced in two styles, the Integrated model platinum melting furnace and the tilting model platinum melting furnace, the Integrated platinum melting machine comes with the design of a crucible that is picked up by a crucible clamp and then poured into the graphite molds, whereas tilting platinum melting machine is designed with the molds attached on the front side of the furnace body and can be poured directly from the crucible

Quartz crucibles or zirconia crucibles are adopted in this platinum melting machine, the melting speed of the platinum melting machine is rapid, which means it can reach a temperature of up to 1800 degrees in less than two minutes.

CDOCAST platinum melting furnace adopts the newest Induction Heating Technology which comes with a warranty time of 2 years, if any quality problem within 2 years, we will be in charge of all fees for maintenance.

CDOCAST platinum melting furnace can melt all types of high melting point metal, such as steel, iron, stainless steel platinum, palladium, rhodium, and metal powder, which is the most ideal furnace for your choice. Inquiry our engineer today.

1kg Small Platinum Melting Furnace:

1kg-10kg Integrated Platinum Melting Furnace:

10kg-15KG Integrated Platinum Melting Furnace:

1kg-15kg Manual Tilting Platinum Melting Furnace:

30kg Manual Tilting Platinum Melting Furnace:

| Description | Size(mm) | ||

| Capacity | Ø1(external) | Ø2(internal) | H1(height) |

| 500g | 48 | 35 | 87 |

| 1kg | 60 | 46 | 100 |

| 3kg | 86 | 60 | 120 |

| 5kg | 90 | 65 | 155 |

| 8kg | 146 | 90 | 190 |

| 10kg | 146 | 100 | 190 |

| Model number | CDO-FM16 | CDO-FM17 | CDO-FM18 | CDO-FM19 | CDO-FM20 |

| Applicable metal | Platinum, palladium, steel , stainless steel | ||||

| Voltage | 3P, 380V, 50/60Hz | 3P, 380 V, 50/60Hz | 3P, 380 V, 50/60Hz | 3P, 380 V, 50/60Hz | 3P, 380 V, 50/60Hz |

| Power | 15kw adjustable | 20kw adjustable | 25kw adjustable | 30kw adjustable | 30kw adjustable |

| Weight | 72 kg | 72kg | 75 kg | 78 kg | 78 kg |

| Max capacity(platinum) | 1kg | 3kg | 5kg | 8kg | 10kg |

| Melting time | 1-3min | 2-4 min | 2-5 min | 3-8 min | 3-10 min |

| Dimension(LWH) | 500*500*860mm | 500*500*860mm | 500*500*860mm | 500*500*860mm | 500*500*860mm |

| Max temperature | 2000℃(Quartz crucible)/2600℃(Zirconia crucible) | ||||

| Cooling way | Water cooling | Water cooling | Water cooling | Water cooling | Water cooling |

| Water pump | Build-in | Build-in | Build-in | Build-in | Build-in |

| Crucible Size | outer:Φ60mm inner:Φ46mm height:100mm |

outer:Φ86mm inner:Φ60mm height:120mm |

outer:Φ90mm inner:Φ65mm height:155mm |

outer:Φ146mm inner:Φ90mm height:190mm |

outer:Φ146mm inner:Φ100mm height:190mm |

1: The Powerful electromagnetic stirring ability can make the molten elted metal more uniform, especially when melting high-temperature alloy, the melting effect is more significant.

2: CDOCAST platinum melting furnace comes with a Built-in water pump, Can Directly work without an external water chiller.

3: Infrared temperature control tester can be installed, and the entire melting temperature can be controlled, to achieve a more accurate melting temperature.

4: The platinum melting furnace is specially designed in Small size &light weight, with sliding wheels on the bottom of each stove. So the full furnace movable

5: Rapid melting speed which can completely melt the platinum or Palladium within 3 mins

6. CDOCAST platinum melting Machine can reach melting temp up to 2000 degrees, Quartz or zirconia crucible can be adopted to this furnace.

Our high temperature platinum melting furnace utilizes advanced medium-frequency induction heating. It can reach up to 2000°C with a quartz crucible. For even higher temperatures, a zirconia crucible enables an extreme melting point of 2600°C. It is perfectly suited not only for platinum (white gold) but also for melting palladium, rhodium, gold, silver, as well as high-melting-point metals like stainless steel and iron, making it a versatile induction melting furnace for precious metals.

Leveraging advanced IGBT solid-state induction technology, our fast melting platinum furnace offers rapid heating. Under normal conditions, it takes only 1-2 minutes to melt 1kg of platinum, significantly boosting production efficiency for jewelers and refiners.

The electromagnetic stirring system is a key feature of our platinum casting furnace. This powerful stirring action causes the molten metal to circulate continuously, ensuring homogeneous distribution of alloying elements and preventing segregation. This is particularly crucial for precise platinum alloy formulation, guaranteeing consistent purity and quality in every casting.

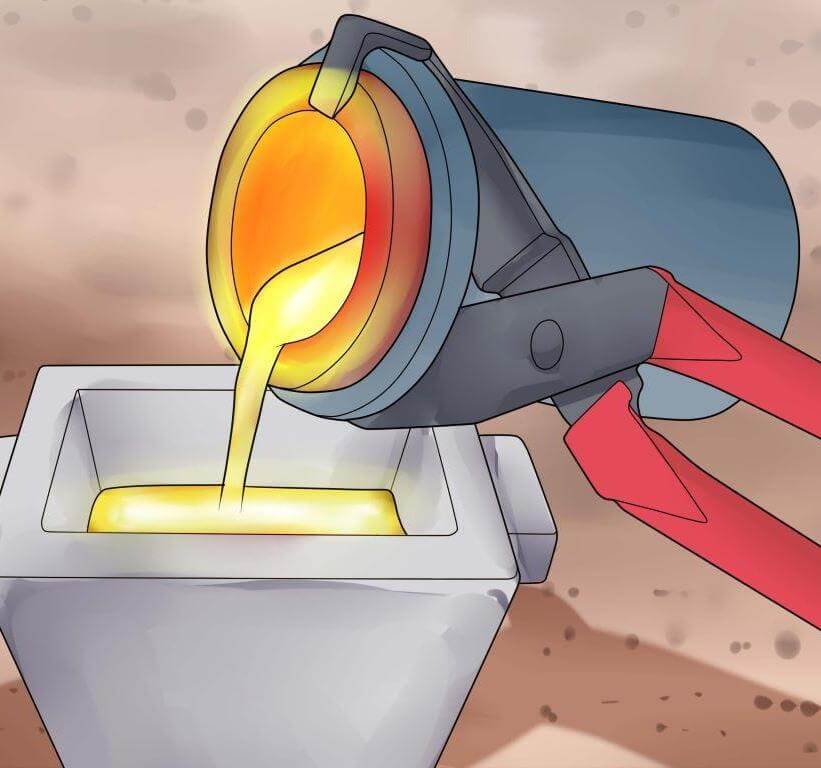

Integrated Model: The crucible is removed using tongs. This model is ideal for small batch platinum melting and offers flexibility for pouring into various molds.

Tilting Model: The mold is typically fixed in front of the furnace, and the entire unit tilts manually or hydraulically for pouring. This design is better suited for large capacity platinum melting (5kg-15kg), offering greater ease of use and enhanced safety.

For platinum and precious metal smelting, we generally recommend the tilting furnace. It allows you to pre-tilt the furnace, bringing the molten metal closer to the spout to pre-heat it. This effectively prevents platinum from solidifying in the spout during pouring by counteracting rapid cooling.

Absolutely. We support global voltage customization for melting furnaces, including 220V single-phase, 220V three-phase, 440V, and others to match your local power standards. The control panel also offers multi-language interfaces including English, Spanish, and Russian.

The CDOCAST furnace comes with a built-in efficient water pump. For small-scale or short-duration operations, connecting it to a water tank is sufficient. For continuous high-intensity melting operations, we recommend connecting an external industrial water chiller for optimal cooling system protection (we can provide a complete cooling solution).

We offer an industry-leading 2-year comprehensive warranty (the standard is typically 1 year). During this period, CDOCAST covers all repair and spare parts costs for any quality-related issues.

Our furnace can be equipped with an optional infrared pyrometer for temperature control. It provides real-time monitoring of the actual metal temperature inside the crucible and feeds data back to the control system, enabling precise temperature regulation for platinum. This ensures precious metals are not damaged or lost due to excessive heat or volatilization.

Note: If the metal has low purity, excessive dross/scum on the surface can significantly impact the accuracy of infrared temperature measurement. In such cases, we do not recommend relying solely on the infrared pyrometer.

Yes, quartz or zirconia crucibles are considered consumables. Their service life depends on the material being melted and the duration of each operation. With proper handling, a quartz crucible can typically be reused approximately 10 times. We maintain ample stock of genuine crucibles in various capacities (1kg-15kg) for easy purchase.

Best for: Continuous production, extreme temperatures (Platinum, Palladium, Rhodium), and high-purity melting applications.

Zirconia Crucible Advantages:

Higher Temperature Resistance: Zirconia’s melting point is near 2700°C, maintaining structural integrity well above 2000°C. Platinum melts at ~1768°C, so zirconia provides a wider safety margin, ideal for a high temperature furnace for platinum.

Superior Chemical Inertness: It has minimal reaction with molten precious metals, effectively preventing contamination and ensuring high platinum melt purity.

Better Thermal Shock Resistance: High-quality zirconia withstands rapid heating/cooling cycles better than standard ceramics.

Zirconia Crucible Disadvantages:

Higher Cost: Significantly more expensive than quartz, classifying it as a premium consumable.

Pre-Heating Requirement: Zirconia crucibles usually require a slow pre-heat cycle before first use or after prolonged storage to prevent micro-cracking from thermal stress, demanding higher user expertise.

Best for: Experimentation, small-batch melting, and budget-conscious operations.

Quartz Crucible Advantages:

Low Cost: Very inexpensive, making frequent replacement less of a financial burden.

Excellent Thermal Shock Resistance: Quartz has an extremely low coefficient of thermal expansion, allowing it to withstand being taken directly from high heat without cracking.

Transparency: Its translucent nature can be helpful for observing the molten metal state in some applications.

Quartz Crucible Disadvantages:

Lower Temperature Limit: Quartz begins to soften and devitrify (become brittle) above 1600°C. While it can be used for platinum, its lifespan at temperatures near 1800°C is very short, often making it a “single-use” or limited-use item for platinum smelting.

Susceptibility to Erosion: At sustained high temperatures, quartz can react with certain metal oxides, leading to inner wall degradation. It is not recommended for customers with stringent requirements on final metal composition.

Our high temperature platinum melting furnace utilizes advanced medium-frequency induction heating. It can reach up to 2000°C with a quartz crucible. For even higher temperatures, a zirconia crucible enables an extreme melting point of 2600°C. It is perfectly suited not only for platinum (white gold) but also for melting palladium, rhodium, gold, silver, as well as high-melting-point metals like stainless steel and iron, making it a versatile induction melting furnace for precious metals.

Leveraging advanced IGBT solid-state induction technology, our fast melting platinum furnace offers rapid heating. Under normal conditions, it takes only 1-2 minutes to melt 1kg of platinum, significantly boosting production efficiency for jewelers and refiners.

The electromagnetic stirring system is a key feature of our platinum casting furnace. This powerful stirring action causes the molten metal to circulate continuously, ensuring homogeneous distribution of alloying elements and preventing segregation. This is particularly crucial for precise platinum alloy formulation, guaranteeing consistent purity and quality in every casting.

Integrated Model: The crucible is removed using tongs. This model is ideal for small batch platinum melting and offers flexibility for pouring into various molds.

Tilting Model: The mold is typically fixed in front of the furnace, and the entire unit tilts manually or hydraulically for pouring. This design is better suited for large capacity platinum melting (5kg-15kg), offering greater ease of use and enhanced safety.

For platinum and precious metal smelting, we generally recommend the tilting furnace. It allows you to pre-tilt the furnace, bringing the molten metal closer to the spout to pre-heat it. This effectively prevents platinum from solidifying in the spout during pouring by counteracting rapid cooling.

Absolutely. We support global voltage customization for melting furnaces, including 220V single-phase, 220V three-phase, 440V, and others to match your local power standards. The control panel also offers multi-language interfaces including English, Spanish, and Russian.

The CDOCAST furnace comes with a built-in efficient water pump. For small-scale or short-duration operations, connecting it to a water tank is sufficient. For continuous high-intensity melting operations, we recommend connecting an external industrial water chiller for optimal cooling system protection (we can provide a complete cooling solution).

We offer an industry-leading 2-year comprehensive warranty (the standard is typically 1 year). During this period, CDOCAST covers all repair and spare parts costs for any quality-related issues.

Our furnace can be equipped with an optional infrared pyrometer for temperature control. It provides real-time monitoring of the actual metal temperature inside the crucible and feeds data back to the control system, enabling precise temperature regulation for platinum. This ensures precious metals are not damaged or lost due to excessive heat or volatilization.

*Note: If the metal has low purity, excessive dross/scum on the surface can significantly impact the accuracy of infrared temperature measurement. In such cases, we do not recommend relying solely on the infrared pyrometer.

Yes, quartz or zirconia crucibles are considered consumables. Their service life depends on the material being melted and the duration of each operation. With proper handling, a quartz crucible can typically be reused approximately 10 times. We maintain ample stock of genuine crucibles in various capacities (1kg-15kg) for easy purchase.

Best for: Continuous production, extreme temperatures (Platinum, Palladium, Rhodium), and high-purity melting applications.

Zirconia Crucible Advantages:

Higher Temperature Resistance: Zirconia's melting point is near 2700°C, maintaining structural integrity well above 2000°C. Platinum melts at ~1768°C, so zirconia provides a wider safety margin, ideal for a high temperature furnace for platinum.

Superior Chemical Inertness: It has minimal reaction with molten precious metals, effectively preventing contamination and ensuring high platinum melt purity.

Better Thermal Shock Resistance: High-quality zirconia withstands rapid heating/cooling cycles better than standard ceramics.

Zirconia Crucible Disadvantages:

Higher Cost: Significantly more expensive than quartz, classifying it as a premium consumable.

Pre-Heating Requirement: Zirconia crucibles usually require a slow pre-heat cycle before first use or after prolonged storage to prevent micro-cracking from thermal stress, demanding higher user expertise.

Best for: Experimentation, small-batch melting, and budget-conscious operations.

Quartz Crucible Advantages:

Low Cost: Very inexpensive, making frequent replacement less of a financial burden.

Excellent Thermal Shock Resistance: Quartz has an extremely low coefficient of thermal expansion, allowing it to withstand being taken directly from high heat without cracking.

Transparency: Its translucent nature can be helpful for observing the molten metal state in some applications.

Quartz Crucible Disadvantages:

Lower Temperature Limit: Quartz begins to soften and devitrify (become brittle) above 1600°C. While it can be used for platinum, its lifespan at temperatures near 1800°C is very short, often making it a "single-use" or limited-use item for platinum smelting.

Susceptibility to Erosion: At sustained high temperatures, quartz can react with certain metal oxides, leading to inner wall degradation. It is not recommended for customers with stringent requirements on final metal composition.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST platinum melting furnace

Contact Our Engineer Team

CDOCAST provide you types of Electric Melting Furnace for you to choose when you want to invest in the furnace.

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

CDOCAST furnace is absolutely inventive designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….