1Finished Products1

1Product Details1

[ Metal extrusion machine ]

Cdocast metal extruding machine is the latest multi-purpose four column horizontal machine developed by our company, which is controlled by microcomputer PLC.

This metal extruder is mainly applicable to:

1. It is applicable to the extrusion of various specifications of copper and copper alloy wires (rods).

2. It is applicable to the extrusion of silver and aluminum alloy wires (rods) of various specifications.

3.cdocast metal extruder is suitable for the extrusion of zinc materials and non-ferrous metal wires.

Metal Extrusion Machine adopts the extrusion die head and adopts the front mode (that is, the extrusion die head is set between the front seat of the oil cylinder and the piston rod), which can completely extrude the materials in the die head at one time, and there are no excessive tailings left in the die head. In the extrusion process, the die head is fixed, and the die is fixed in the die head. After extrusion, each rod does not need to cut off the extruded tailings. It is extruded one by one. The extruded wire rod is continuous, and the joint connection is tight. The die head is designed with an automatic opening and closing structure. The die head is opened and closed. When replacing the die, just press the die opening button, and the two front oil cylinders will push the die head open, which can easily remove the die

Machine Details

Parameter

| Model number | CDO-EX250T | CDO-EX350T | CDO-EX500T | CDO-EX600T | CDO-EX800T |

| Master cylinder maximum thrust | 250T | 350T | 500T | 600T | 800T |

| Voltage | 380V | 380V | 380V | 380V | 380V |

| Master cylinder maximum pressure | 22 MPa | 25 MPa | 24 MPa | 24 MPa | 31.5MPa |

| Billet size | Φ40*140mm | Φ50*150mm | Φ60*150mm | Φ70*150mm | Φ80*150mm |

| Main Cylinder Length | 450mm | 450mm | 500mm | 500mm | 650mm |

| Forward Speed | 150mm/s | 150mm/s | 150mm/s | 150mm/s | 200mm/s |

| Withdraw Speed | 200mm/s | 200mm/s | 200mm/s | 200mm/s | 250mm/s |

| Main motor power | 7.5KW | 11KW | 11KW | 11KW | 22KW |

| General Power | 14KW | 19KW | 30KW | 30KW | 32KW |

| Machine dimension | 4000*1500*1400mm | 4200*1500*1400mm | 5000*1600*1600mm | 5000*1600*1600mm | 5500*1800*1600mm |

| Weight | 4000KGS | 4500KGS | 6000KGS | 7000KGS | 8000KGS |

Feature

Metal Extrusion Machine Feature:

1. Master cylinder: piston cylinder (German technology) is adopted. working pressure error (0.002kg), with the characteristics of strong and constant speed stability, the hydraulic system ensures the stability of metal flow extrusion and makes the connection firm at the interface.

2. The Metal Extrusion Machine comes with Built-in sub cylinder: It has the function of rapid oil filling, reducing no-load time, quickly reaching the working pressure, and improving efficiency.

3. CDOCAST metal extruder adopts four guide rod structure, which makes the rigidity of the machine better and fully improves the balance of extrusion.

4. The die head of the machine adopts the front mode, and the extrusion die head is set between the front seat of the oil cylinder and the piston rod. Because the machine adopts the continuous extrusion mode, there is no need to make the extrusion discus used by other manufacturers in the extrusion process, so many intermediate processes and actions are simplified.

5.5. The die head of the machine adopts the front, and an opening and closing movable plate is added. The extrusion die head is installed on this plate, and two oil cylinders are provided to support it from both sides to prevent the movable plate from retreating. When it needs to be opened, the movable plate is pulled and slid through the two oil cylinders to facilitate the assembly and disassembly of the extrusion die.

6. The extrusion die head adopts double-layer structure and is made of special high-temperature resistant materials through special heat treatment process. It has the characteristics of high pressure resistance, high temperature resistance and high hardness, so as to prevent the risk of hardness reduction due to the increase of die head temperature. The die head of the machine is heated by electromagnetic induction heating, which is efficient and fast, which can not be realized by using resistance heating ring. However, the use of electromagnetic induction heating can realize various temperatures required by the die head process, and can better meet the requirements of various production processes.

7. The Metal Extrusion Machine has the ability of automatic mold opening and closing and mold out. It is equipped with two mold opening and closing oil cylinders, which are placed on the left and right sides of the machine. After the oil cylinder pushes open the movable plate of the movable die head, it is equipped with a mold-out oil cylinder, which is installed on the front seat. The mold-out oil cylinder pushes the mold base plate. The mold base plate is equipped with two holes, one for extruding the outlet hole and the other for mold out hole, When the die base plate is pushed to the die outlet hole, after the die base movable plate is attached, the extrusion ejector rod can push the die out of the die base, which is easy and convenient, and the die change is convenient and fast.

8. The extrusion die and extrusion rod are forged with high temperature resistant special materials and processed by a special heat treatment process. They have the characteristics of high pressure resistance, high temperature resistance and high wear resistance. Because the machine does not need to use extrusion pad in the extrusion process, it has higher requirements for the performance and accuracy of ejector rod and die, so as to ensure the stability and continuity of extrusion.

9. The front seat and rear seat of the machine are made of steel castings to ensure the strength and rigidity of the machine, and ensure the coaxiality and perpendicularity of the ejector rod and the die head are still maintained under high pressure during extrusion.

10. The Metal Extrusion Machine adopts an advanced hydraulic system and is equipped with two sets of systems, which are divided into a high-pressure system and low-pressure system. The main cylinder and fast cylinder adopt high-pressure system, and the mold opening, closing and ejection devices adopt low-pressure system. The high-pressure system is composed of two oil pump motors. The main pump motor is mainly used to squeeze the workpiece, and the other is an auxiliary motor for rapid oil filling and pressure starting. When the rapid oil filling is completed, it will be converted to circulating hydraulic oil for cooling through the cooler to prevent the oil temperature from rising

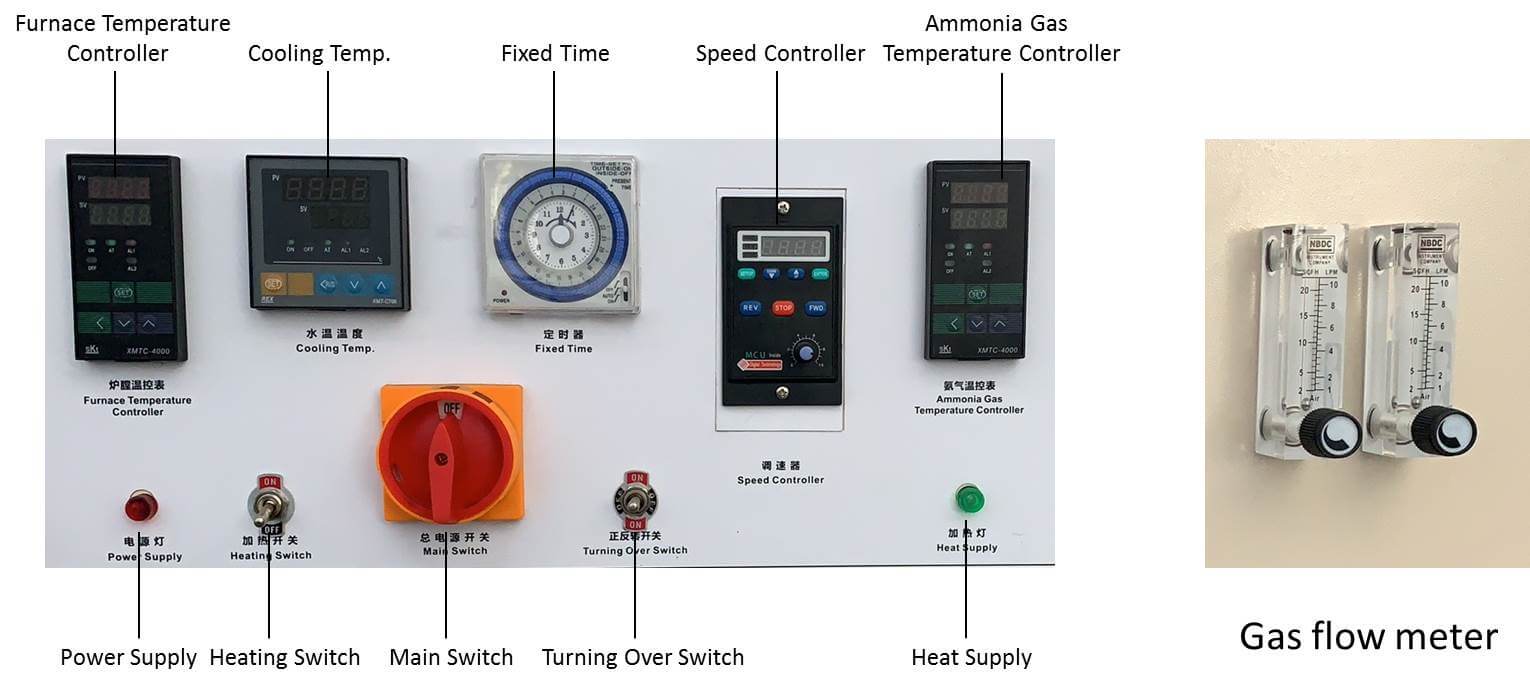

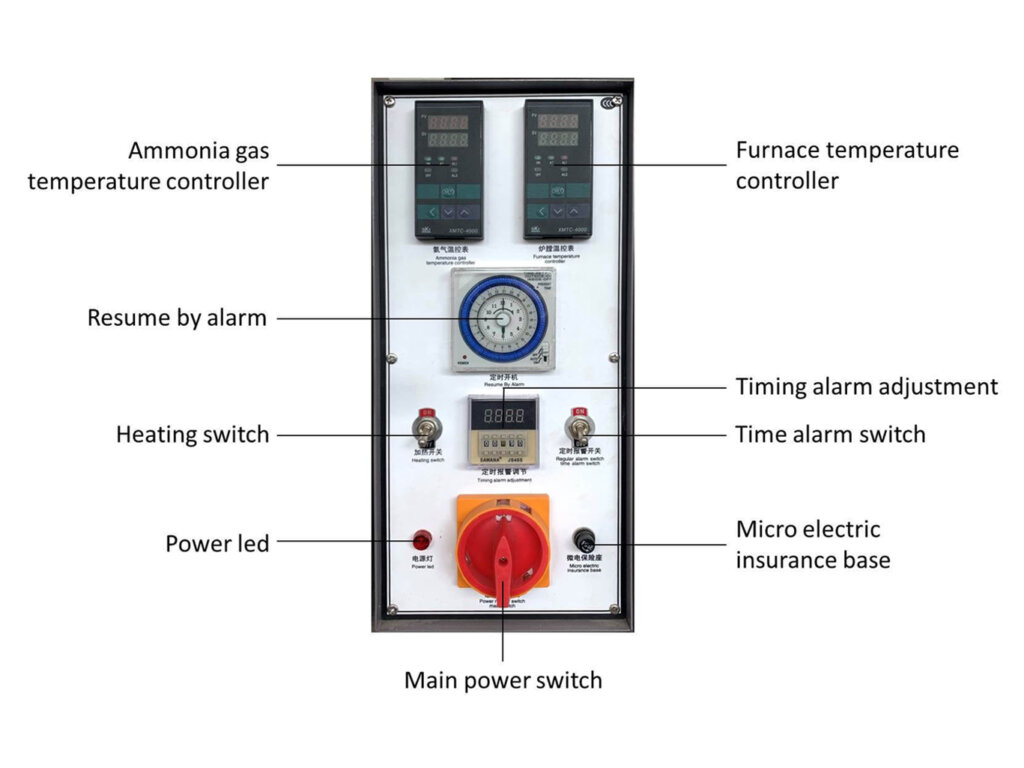

Operation panel:

Operation panel:

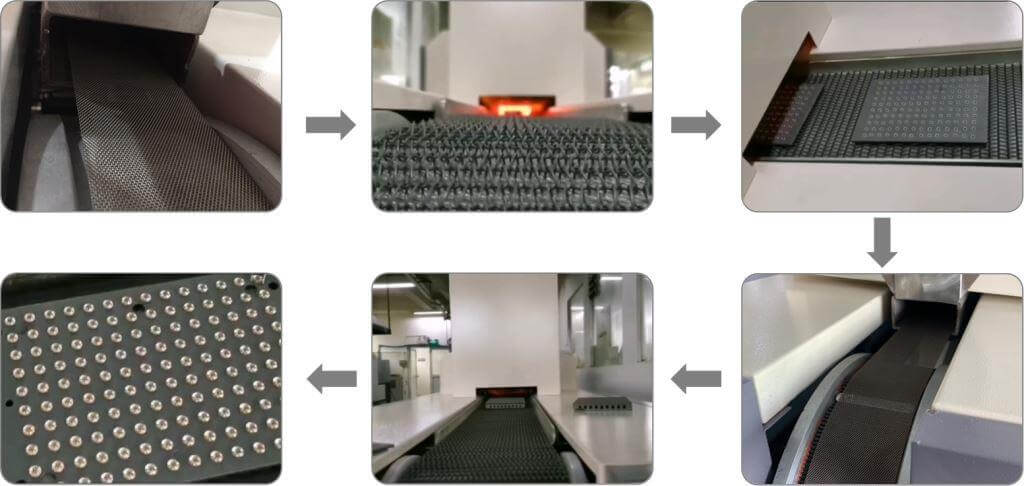

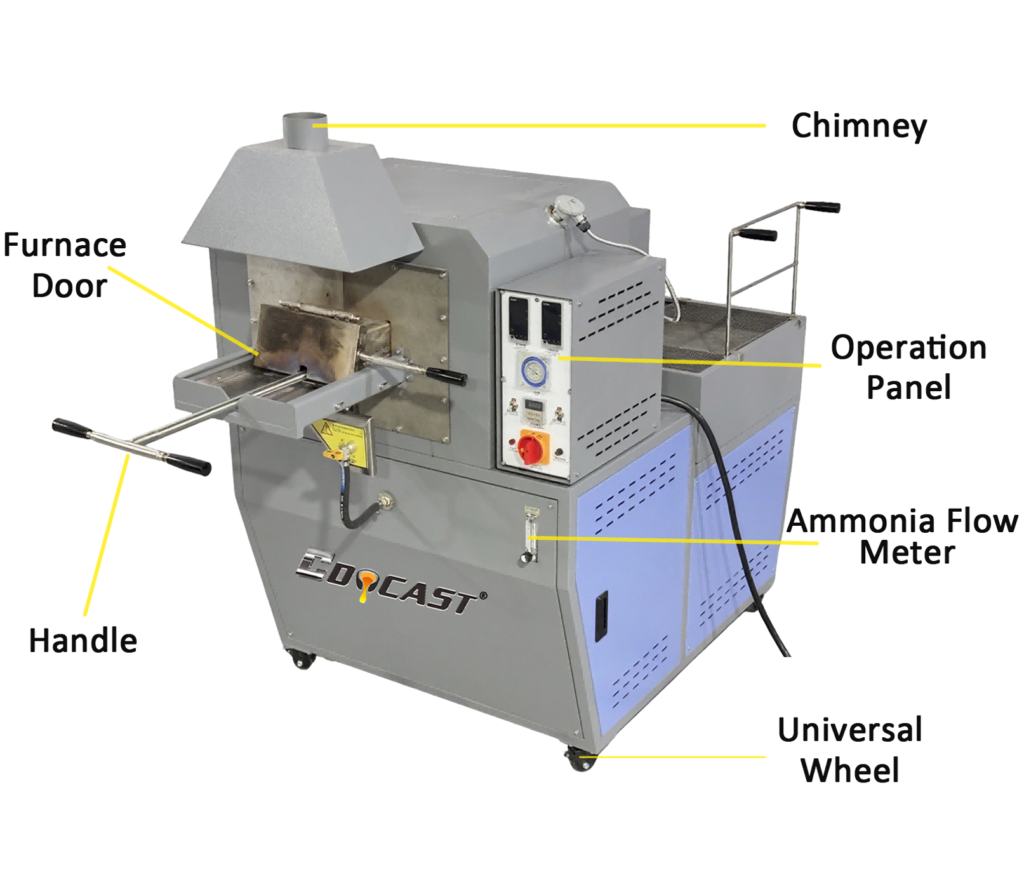

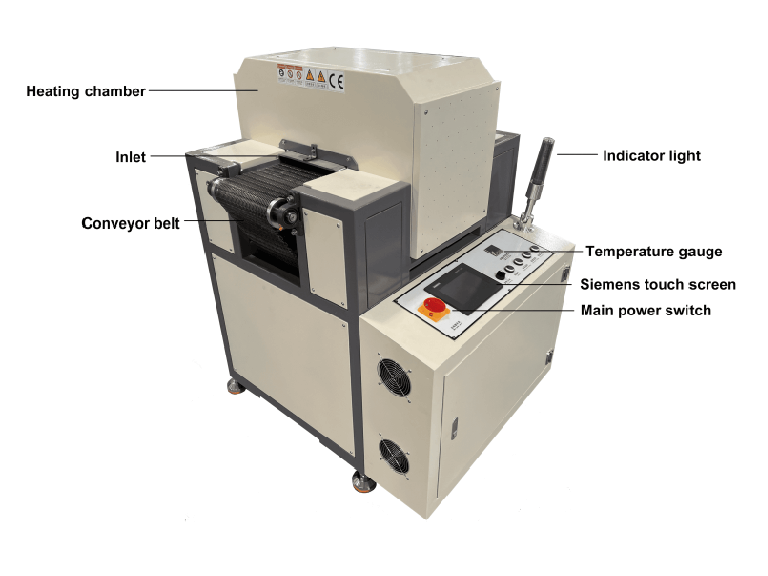

1 Meter Channel Annealing Furnace:

1 Meter Channel Annealing Furnace:

Precious Metal Laser Cutting Machine

Precious Metal Laser Cutting Machine