1Product Shows1

1Product Details1

[what is Air cooled water chiller]

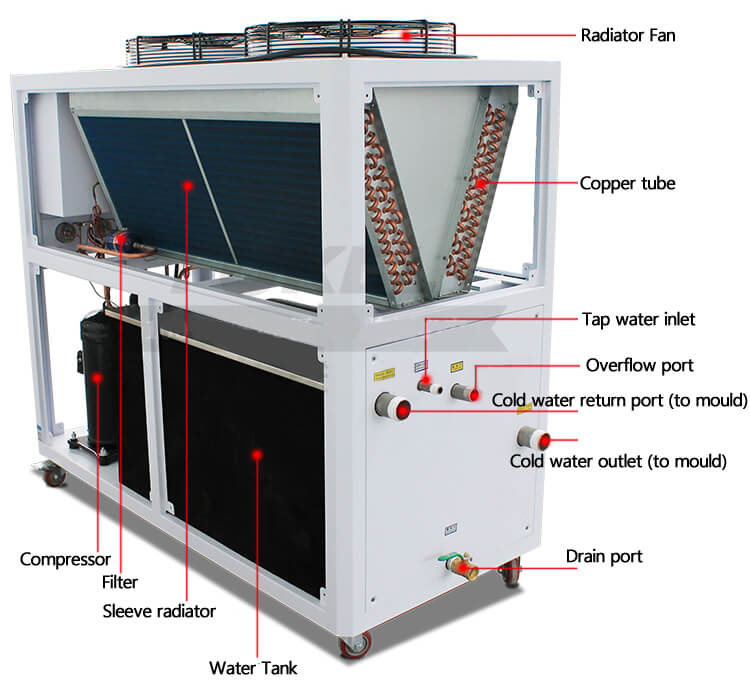

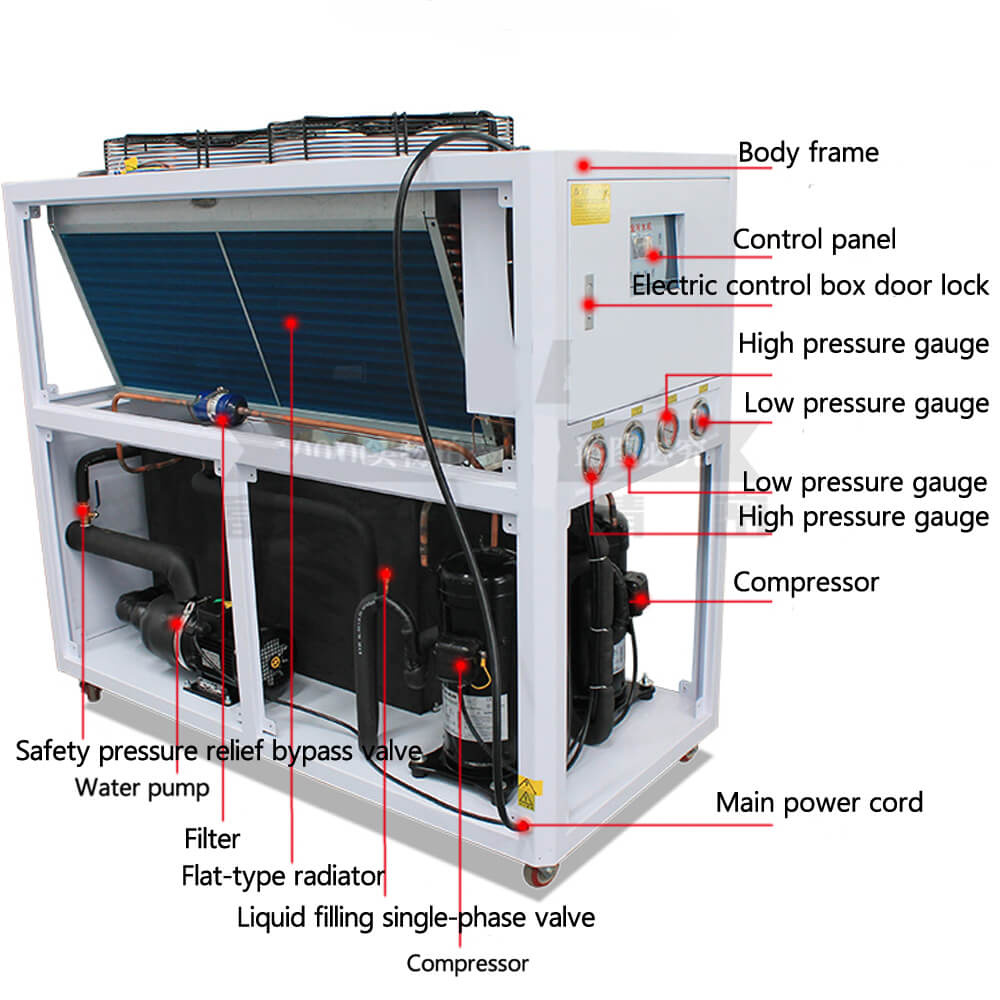

Air-cooled water chiller is one of the models of water chiller, the normal temperature water will be cooled to a certain temperature through the compressor of the chiller to strengthen the cooling mold or machine, as a stand-alone use, the radiator is a built-in fan, there are three interconnected systems: refrigerant circulation system, water circulation system, electric automatic control system.

The air-cooled water chiller model is compact, small and movable. CDOCAST water chillers are mainly used in the cooling of intermediate frequency furnace and continuous casting, mainly applied in the process of lowering the temperature of the power supply furnace, to protect the whole equipment from the damage of high temperature. Sometimes, it is also used in the cooling of semi-products cooling.

Machine Pictures

Parameter

| Model number | CDO-W3P | CDO-W5P | CDO-W10P | CDO-W15P | CDO-W20P | CDO-W30P |

| Cooling temperature | 5-35℃ | |||||

| Voltage | 380V, 3P, 50/60Hz | |||||

| Refrigerating capacity | 7216Kcal/h | 12790Kcal/h | 28184Kcal/h | 44419 Kcal/h | 59442Kcal/h | 87741Kcal/h |

| Total power | 3.6KW | 5.5KW | 11KW | 17KW | 22.7KW | 30KW |

| Max current | 8.8A | 13.3A | 26.3A | 41.3A | 55.4A | 76.8A |

| Compressor power | 2.25KW | 3.75KW | 7.5KW | 11.25KW | 15KW | 22.5KW |

| Air fan power | 0.36KW | 0.36KW | 0.6KW | 1.1KW | 1.1KW | 3.3KW |

| Cooling water flow | 5m³/h | 5 m³/h | 12 m³/h | 16m³/h | 16m³/h | 20m³/h |

| Water tank capacity | 65L | 110L | 188L | 350L | 400L | 480L |

| Pump power | 0.55kw | 0.55kw | 1.5KW | 1.85KW | 2.2KW | 3KW |

| Hydraulic head | 20M | 25M | 20M | 20M | 30M | 28M |

| Weight | 100KG | 220KG | 350KG | 490KG | 590KG | 850KG |

| Overall dimension(cm) | 118*60*100 | 130*55*135 | 156*70*137 | 170*70*162 | 190*80*173 | 260*100*180 |

Feature

1:The compressor unit adopts vortex type hermetically sealed compressor and electric control components, and is equipped with condenser and evaporator made of high quality copper tube for heat transfer and high efficiency.

2:CDOCAST water chiller Equipped with all kinds of safety protection devices, stable performance, low noise, long service life, simple operation; the use of liquid crystal display man-machine interface, simple and convenient operation, operating conditions at a glance.

3:The water chiller are equipped with single compressor or multi-compressor combined refrigeration system. The compressor can automatically alternate the operation according to the load change and balance the running hours of each compressor to save energy and extend the service life of the chiller set. It is convenient for energy adjustment and more energy-saving at partial load.

4:the whole water chiller designed with shell box structure & attractive appearance &compact structure, the chiller can be checked at any time; the chiller comes with its own water tank and circulating water pump according to the cooling capacity, without the need for installation of cooling tower and cooling water pump, installation and maintenance is simple and convenient.

Catalog

Q1. Why is your water chiller priced higher than some competitors?

Our chillers are high-end industrial cooling systems powered by Siemens Control Systems, offering significant advantages over standard brands:

(1) Unmatched Stability:** Siemens PLC and touchscreens are designed for harsh industrial environments, providing superior resistance to electromagnetic interference, vibration, and humidity. This minimizes downtime risks for your melting line.

(2) Precision Temperature Control:** Utilizing advanced **PID algorithms**, our system achieves ultra-precise cooling with fluctuations as low as **±0.1°C to ±0.3°C**.

(3) Energy Efficiency:** The intelligent control dynamically adjusts the speed of the **compressor, pump, and fan** based on the actual heat load, preventing energy waste.

(4) Easy Installation:** Our air-cooled design requires no external cooling tower, making it ideal for facilities with limited water sources or high mobility requirements.

Q2: What determines the actual cooling performance of a chiller?

Cooling capacity is determined by how much heat can be moved from the source (Melting Furnace) to the environment per unit of time. (1) Refrigeration System (90% Impact):** The real "heat mover" is the combination of the **Compressor (Copeland or Panasonic)**, **Evaporator (Copper)**, and **Condenser**. The compressor's power directly dictates the maximum cooling capacity. (2) Water Tank (10% Impact):** A larger tank provides "thermal inertia" and stability, acting as a buffer during load fluctuations, but it does not generate cooling power itself.

Q3: Why do you use Stainless Steel water tanks instead of Cast Iron?

Most low-cost suppliers use cast iron, but we prioritize water purity and longevity for precious metal casting.

Q4: How long is the service life of your water chiller?

(1)Continuous 24/7 Operation: Refrigerant typically needs replacement every 6-7 years.

(2)Daily Use (2-3 Hours): Service life can extend to 10 years before refrigerant replacement.

Note: We do not recommend use in strong acid/base environments or unprotected outdoor settings.

Q5. What is the ideal installation spacing for multiple chillers?

Proper ventilation is key to preventing high-temperature alarms:

Between Units: Maintain 1.0 - 1.5 meters.

Against a Wall: Maintain at least 0.8 - 1.0 meter for optimal heat dissipation.

Q6. My chiller has a High-Temperature Alarm. What should I do?

Common causes include:

(1)Poor Ventilation: Ensure the unit isn't in a cramped space. Moving it to a well-ventilated outdoor area (under a rain cover) can help.

(2)Dirty Water:** Change the water every 2-3weeks, especially when melting gold and silver, to maintain efficiency.

Q7: Is a more powerful water pump always better?

No. Excessive pump pressure or power can lead to high-load damage or even cause water pipes and joints to burst. Conversely, insufficient pressure leads to poor cooling. We match the pump power specifically to your melting equipment's needs.

Q8: How do I choose the right chiller model for my melting furnace?

Model selection is customized based on your furnace power (kW), usage frequency, and ambient temperature. Please provide your equipment specs, and our engineers will design the most cost-effective cooling solution for you.

Common Questions about Water Chiller

Our chillers are high-end industrial cooling systems powered by Siemens Control Systems, offering significant advantages over standard brands:

(1) Unmatched Stability: Siemens PLC and touchscreens are designed for harsh industrial environments, providing superior resistance to electromagnetic interference, vibration, and humidity. This minimizes downtime risks for your melting line.

(2) Precision Temperature Control:Utilizing advanced PID algorithms, our system achieves ultra-precise cooling with fluctuations as low as ±0.1°C to ±0.3°C.

(3) Energy Efficiency:The intelligent control dynamically adjusts the speed of the compressor, pump, and fan** based on the actual heat load, preventing energy waste.

(4) Easy Installation: Our air-cooled design requires no external cooling tower, making it ideal for facilities with limited water sources or high mobility requirements.

Cooling capacity is determined by how much heat can be moved from the source (Melting Furnace) to the environment per unit of time.

(1) Refrigeration System (90% Impact): The real “heat mover” is the combination of the Compressor (Copeland or Panasonic), Evaporator (Copper), and Condenser. The compressor’s power directly dictates the maximum cooling capacity.

(2) Water Tank (10% Impact): A larger tank provides “thermal inertia” and stability, acting as a buffer during load fluctuations, but it does not generate cooling power itself.

Most low-cost suppliers use cast iron, but we prioritize water purity and longevity for precious metal casting

(1) Continuous 24/7 Operation:Refrigerant typically needs replacement every 6-7 years.

(2) Daily Use (2-3 Hours):Service life can extend to 10 years before refrigerant replacement.

Note: We do not recommend use in strong acid/base environments or unprotected outdoor settings.

(1) Proper ventilation is key to preventing high-temperature alarms:

(2) Between Units: Maintain 1.0 – 1.5 meters.

Against a Wall: Maintain at least 0.8 – 1.0 meter for optimal heat dissipation.

(1) Poor Ventilation: Ensure the unit isn’t in a cramped space. Moving it to a well-ventilated outdoor area (under a rain cover) can help.

(2) Dirty Water:** Change the water every2-3weeks, especially when melting gold and silver, to maintain efficiency.

No. Excessive pump pressure or power can lead to high-load damage or even cause water pipes and joints to burst. Conversely, insufficient pressure leads to poor cooling. We match the pump power specifically to your melting equipment’s needs.

Model selection is customized based on your furnace power (kW), usage frequency, and ambient temperature. Please provide your equipment specs, and our engineers will design the most cost-effective cooling solution for you.

Q1. Why is your water chiller priced higher than some competitors?

Our chillers are high-end industrial cooling systems powered by Siemens Control Systems, offering significant advantages over standard brands:

(1) Unmatched Stability:** Siemens PLC and touchscreens are designed for harsh industrial environments, providing superior resistance to electromagnetic interference, vibration, and humidity. This minimizes downtime risks for your melting line.

(2) Precision Temperature Control:** Utilizing advanced **PID algorithms**, our system achieves ultra-precise cooling with fluctuations as low as **±0.1°C to ±0.3°C**.

(3) Energy Efficiency:** The intelligent control dynamically adjusts the speed of the **compressor, pump, and fan** based on the actual heat load, preventing energy waste.

(4) Easy Installation:** Our air-cooled design requires no external cooling tower, making it ideal for facilities with limited water sources or high mobility requirements.

Q2: What determines the actual cooling performance of a chiller?

Cooling capacity is determined by how much heat can be moved from the source (Melting Furnace) to the environment per unit of time. (1) Refrigeration System (90% Impact):** The real "heat mover" is the combination of the **Compressor (Copeland or Panasonic)**, **Evaporator (Copper)**, and **Condenser**. The compressor's power directly dictates the maximum cooling capacity. (2) Water Tank (10% Impact):** A larger tank provides "thermal inertia" and stability, acting as a buffer during load fluctuations, but it does not generate cooling power itself.

Q3: Why do you use Stainless Steel water tanks instead of Cast Iron?

Most low-cost suppliers use cast iron, but we prioritize water purity and longevity for precious metal casting.

Q4: How long is the service life of your water chiller?

(1)Continuous 24/7 Operation: Refrigerant typically needs replacement every 6-7 years.

(2)Daily Use (2-3 Hours): Service life can extend to 10 years before refrigerant replacement.

Note: We do not recommend use in strong acid/base environments or unprotected outdoor settings.

Q5. What is the ideal installation spacing for multiple chillers?

Proper ventilation is key to preventing high-temperature alarms:

Between Units: Maintain 1.0 - 1.5 meters.

Against a Wall: Maintain at least 0.8 - 1.0 meter for optimal heat dissipation.

Q6. My chiller has a High-Temperature Alarm. What should I do?

Common causes include:

(1)Poor Ventilation: Ensure the unit isn't in a cramped space. Moving it to a well-ventilated outdoor area (under a rain cover) can help.

(2)Dirty Water:** Change the water every 2-3weeks, especially when melting gold and silver, to maintain efficiency.

Q7: Is a more powerful water pump always better?

No. Excessive pump pressure or power can lead to high-load damage or even cause water pipes and joints to burst. Conversely, insufficient pressure leads to poor cooling. We match the pump power specifically to your melting equipment's needs.

Q8: How do I choose the right chiller model for my melting furnace?

Model selection is customized based on your furnace power (kW), usage frequency, and ambient temperature. Please provide your equipment specs, and our engineers will design the most cost-effective cooling solution for you.

-150x150.png)