- Call Us: 008615168765707

- Mail Us: [email protected]

Metal granulator with medium frequency induction heating technology

In the world of precious and non-ferrous metal processing, achieving consistent, spherical, and high-purity metal granules is essential for a wide range of industrial and commercial applications. Our metal granulation machines are expertly engineered to meet these demands, offering unmatched precision, reliability, and flexibility for metals like gold, silver, copper, and various alloys. With capacities ranging from 2kg to 500kg, our systems are designed to serve both small-scale workshops and large industrial production facilities.

The metal granulator produced by CDOCAST is applied to produce various metal grains, such as gold, silver, K gold, copper, etc. The metal granulator includes three parts: the furnace, the water tank, and the loading frame. The molten metal will flow through the pure graphite comes with multiple at the bottom, and the whole granulation process is protected by inert gas argon or nitrogen, which minimizes the oxidation of metal.

We understand that different production volumes require different solutions. That’s why we offer two distinct structural designs optimized for efficiency and ease of use:

– Integrated Units (2kg – 50kg):

These compact, all-in-one systems are perfect for laboratories, R&D centers, and small-batch producers. The melting and granulating components are housed within a single robust structure, saving space while ensuring seamless operation. Their user-friendly design allows for quick setup and minimal operator training.

– Platform-Based Systems (50kg – 500kg):

For medium to high-volume production, our platform-type systems provide enhanced stability and efficiency. The melting unit is positioned on an elevated platform, allowing molten metal to flow smoothly into the granulation water tank below. This separation not only improves operational safety but also facilitates maintenance and process monitoring.

At the heart of each system lies our advanced medium-frequency induction melting technology. It ensures rapid, uniform heating and precise temperature control—critical for maintaining metal integrity and fluidity.

The granulation process begins once the metal is fully melted. The molten material flows through precision-drilled holes at the bottom of the crucible into a cooling water tank, forming perfectly round and uniform granules.

What sets our machines apart is the **customizable hole size** at the base of the crucible. Depending on whether you require 1mm, 3mm, or larger granules, we tailor the discharge holes to meet your exact specifications, giving you full control over the final product size.

Producing high-quality alloy granules requires more than standard equipment. To address this, we offer:

– Stirring Granulation Technology:

Our stirring-type granulators are specifically recommended for alloy processing. By stirring the molten metal during the heating process, these machines achieve a homogenous mixture, resulting in uniform composition and perfectly shaped alloy granules with consistent properties.

– Vacuum Granulation for Superior Results:

For metals that are prone to oxidation (such as certain copper and silver alloys), we provide vacuum granulation systems. These units operate in an oxygen-free environment, preventing oxidation and producing exceptionally bright, clean, and spherical granules. While this advanced technology represents a higher investment, it is indispensable for applications where purity and surface quality are critical.

CDOCAST can customized different metal granulator for customers according to different metals ,different capacities, and different production efficiency for each client, welcome to inquiry us now!

Small Metal Granulation Tank

6-12kg Gold Silver Grain Making Machine

20-50kg Metal Granulator with Graphite Plug

10-50kg Vacuum Metal Granulator

50-500kg Platform Type Metal Granulating Machine

Structure of Gold &Silver Granulator

A gold silver granulator is a specialized machine used to produce high-quality gold granules, which are essential for applications in jewelry making, electronics, and industrial processes. One of the key components of a gold silver granulator is the **graphite crucible with a stopper rod**, which plays a critical role in controlling the flow of molten gold and ensuring consistent granule production. Below is an overview of the structure and functionality of this system.

### **1. Graphite Crucible**

The graphite crucible is the core component of the gold granulator, designed to withstand high temperatures and chemical corrosion. It is made from high-purity graphite, which offers excellent thermal conductivity and durability. The crucible is responsible for holding and melting the gold or silver

– **Material**: High-purity graphite ensures minimal contamination of the molten gold or silver.

– **Design**: The crucible is typically cylindrical with a tapered bottom to facilitate the flow of molten gold.

– **Heating**: The crucible is heated using an induction Heating furnace to melt the gold or silver at temperatures above 1,064°C (1,947°F).

### **2. Stopper Rod System**

The stopper rod is a precision mechanism that controls the flow of molten gold from the crucible into the granulation chamber. It consists of several key parts:

– **Rod Material**: The stopper rod is also made from high-quality graphite or ceramic to withstand high temperatures and resist wear.If the material is easily contaminated by graphite, we will also use boron nitride material as the plug rod

– **Sealing Mechanism**: The rod fits tightly into an opening at the bottom of the crucible, creating a seal to prevent molten gold from leaking.

– **Actuation System**: The stopper rod is connected to a manual or automated control system (e.g., pneumatic or electric actuator) that allows precise adjustment of the rod’s position. This controls the flow rate of the molten gold.

### **3. Granulation Chamber**

Below the crucible and stopper rod is the granulation chamber, where the molten gold is transformed into granules. This chamber typically includes:

– **Cooling Medium**: Water is mostly used to rapidly cool the molten gold droplets, solidifying them into granules.

– **Collection Tray**: A tray or container collects the solidified granules for further processing. CDOCAST granulator adopt the automatic lifting up tray to collect the granules, which can greatly reduce the cost the the production labour

### **4. Control System**

The gold granulator is equipped with a control system to regulate the melting and granulation process. This system includes:

– **Temperature Control**: Ensures the gold is melted at the optimal temperature.

– **Inert Gas Flow Control**: Adjusts the Inert Gas Flow Rate to get the most shinning and fine granules.

– **Automation**: Advanced granulators may feature automated controls for precise and repeatable operation.

### **5. Advantages of the Graphite Crucible with Stopper Rod**

– **Precision**: The stopper rod allows precise control over the flow of molten gold, ensuring uniform granule size.

– **Durability**: Graphite components are highly resistant to thermal and chemical degradation.

– **Efficiency**: The system enables continuous and efficient production of high-quality gold granules.

### **Conclusion**

The graphite crucible with a stopper rod is a critical component of a gold and Silver granulator, enabling precise control over the melting and granulation process. Its robust design and high-temperature resistance make it ideal for producing consistent, high-quality gold granules. By understanding the structure and functionality of this system, manufacturers can optimize their granulation processes and achieve superior results.

| Model | CDO-MG05 | CDO-MG10 | CDO-MG25 | CDO-MG35 | CDO-MG45 | CDO-MG55 |

| Power | 12kw | 15kw | 18kw | 35kw | 45kw | 55kw |

| Voltage | 380V(220V), 3 phase, 50/60Hz | 380V(220V), 3 phase, 50/60Hz | 380V, 3 phase, 50/60Hz | |||

| Applicable metal | Gold, K-Gold, Silver, Copper, Brass, Bronze | |||||

| Max temperature | 1600℃ | 1600℃ | 1600℃ | 1600℃ | 1600℃ | 1600℃ |

| Melting time | 2-5mins | 2-5mins | 5-8mins | 10-15mins | 10-20mins | 20-30mins |

| Granulating time | About 5mins | About 5mins | About 10mins | About 15mins | About 20mins | About 30mins |

| Casting method | Gravity granulation | Gravity granulation | Gravity granulation | Gravity granulation | Gravity granulation | Gravity granulation |

| Max capacity | Gold: 2kg Silver: 1 kg |

Gold: 4 kg Silver: 2 kg |

Gold: 6-12 kg Silver: 3-6 kg |

Gold: 40 kg Silver: 20 kg |

Gold: 60 kg Silver: 30 kg |

Gold: 100 kg Silver: 50 kg |

| Overall size | 1000*500*965mm | 1000*500*965mm | 1150*500*1100mm | 1610*1550*1930mm | 1610*1550*1930mm | 1610*1550*1930mm |

| Weight | 150kg | 150kg | 270kg | 600kg | 700kg | 750kg |

1. The granulator is used to produce high-quality precious metal particles and alloy particles with uniform color. The finished beads have no oxidation, high density, and no pores, with especially good spherical surfaces, uniform particles, and stable color.

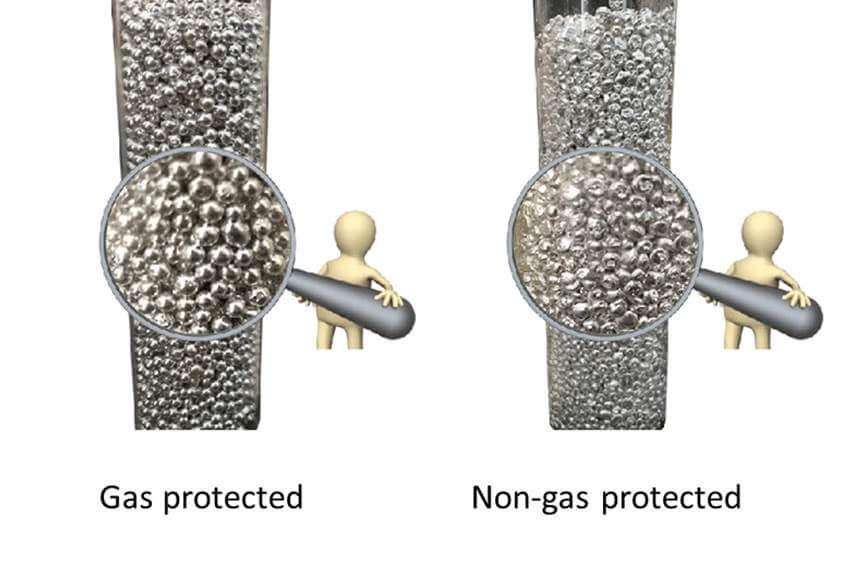

2. The metal granulator comes with Inert gas protection system, which minimizes oxidation in the process of metal melting and casting, especially suitable for precious metals and alloy metals that are easily oxidized. It also reduces the loss of smelted metal and increases the life of the crucible.

3. Applied with the Intermediate frequency induction heating technology, rapid melting speed, it takes about 15 minutes to melt one batch, and the casting time is about 15 minutes, which means that you will get high-quality metal grains within half an hour.

4. The temperature can reach 1600°C, the granulation time is 20-30 minutes, and the melting and granulation are completed in one. After the casting is completed, the pelletizing barrel is easy to take out.

5. Pure graphite crucible comes with quartz jacket as protection, the multihole design at the bottom can act as a breaker to make the molten metal cast into grains. What is more, it only takes 5 minutes to replace new crucible, which is very convenient for the operator

6. Special cooling water to prevent adhesion of metal particles and make particles more evenly formed.

7. Metal granulator melting chamber and water tank can be designed separately or as an integrated unit. If there is not enough space for the user, we will recommend the integrated unit, which takes up less space.

8. The detailed and complete self-diagnosis system and protection function ensure that the equipment failure rate is low.

9. After the melt is completed, the casting speed is fast, making the metal particles smooth and smooth without sand holes.

10. CDOCAST provides 2 years of after-sales service, which minimizes customers’ concerns about after-sales service.

– Uniform Granules: Every batch produces smooth, round, and size-consistent metal particles.

– High Efficiency: Medium-frequency melting ensures quick processing with low energy consumption.

– Durability & Low Maintenance: Built with industrial-grade materials for long-term reliability.

– Customization Options: From discharge hole sizing to overall configuration, we adapt the machine to your needs.

✔ Precious metal refining and recycling

✔ Jewelry and decorative item manufacturing

✔ Electronic component production

✔ Metal powder and additive manufacturing feedstock

✔ Catalysts and chemical processing

We know that every customer has unique production requirements and budget considerations. Whether you need a standard model for copper granulation or a vacuum system for high-purity silver granules, our team is ready to assist you in selecting the ideal equipment.

Whether you need a standard machine for copper granulation or a vacuum system for high-purity gold granules, we are here to support your production goals with cutting-edge technology and expert guidance.

*Contact us today* for a detailed consultation or request a personalized quotation. Let us help you optimize your metal granulation process with machines designed for quality, efficiency, and reliability.

Q1: What is the warranty period for the machines?

A: All CDOCAST machines come with a comprehensive 2-year warranty. During this period, we provide free remote video diagnostics. Any components that fail or are damaged under non-abusive conditions will be replaced free of charge. If a machine fails due to a manufacturing defect, we will provide a complete machine replacement at no cost.

Q2: What is the typical service life for graphite crucibles, nozzles, and stopper rods?

A: The lifespan varies by component and usage:

*Graphite Crucible: 30 – 50 cycles

*Nozzle (Tip): 10 – 20 cycles

*Stopper Rod: 20 – 30 cycles

Q3: Do you provide operation manuals and instructional videos?

A: Yes, every machine is shipped with a detailed specification sheet and a comprehensive operation manual. If you require on-site technical support, we can dispatch an engineer for installation and commissioning. The service fee is USD $150 per day, excluding airfare, visa, and accommodation.

Q4: Can the voltage and frequency be customized?

A: Our standard granulators support 380V, 50Hz/60Hz, 3-Phase. Models with a capacity below 4kg also support 220V, 50Hz/60Hz, 1-Phase. The input voltage can fluctuate within a ±10% range. For other voltage requirements, we recommend using a transformer.

Q5: How do I choose the right granulator for melting alloys or easily oxidized metals?

A: For Alloys (e.g., K-gold): We recommend a granulator with a stirring device. This ensures a homogeneous mixture by preventing the different metal components from stratifying during melting, resulting in uniform alloy granules.

For Oxidizable Metals: We recommend a granulator with a vacuum system. This actively removes oxygen from the melting chamber, drastically reducing oxidation for a higher-quality final product.

Q6: Can I use the same nozzle for different materials?

A: No. Different materials have varying fluidity, melting points, and stability. Using the same nozzle can lead to clogging. Each material requires a nozzle with a specific number and diameter of holes. For example:

Gold Granules: Nozzle diameter of 0.8mm

Silver Granules: Nozzle diameter of 1.0mm

Copper Granules: Nozzle diameter of 1.2mm

Q7: What is the cycle time for melting and granulation per batch?

A: The time varies by machine capacity. For example:

4kg Granulator: Melting time 2-5 minutes; Granulation time 2-3 minutes.

10kg Granulator: Melting time 5-8 minutes; Granulation time 3-5 minutes.

Please refer to the specific technical parameters for each machine model.

Q8: Can the machine perform melting and granulation simultaneously?

A: Yes, but this is only feasible with our 2kg to 4kg models. These machines can be used for both functions by switching between a crucible with a hole (for granulation) and one without (for melting). For 6kg and larger models, the crucible is located inside a sealed furnace chamber, making it dangerous to remove during operation; therefore, these are designed for granulation only.

Q9: How should I preheat a new graphite crucible?

A: When using a new crucible or one that has been idle for several days, always preheat it at low power (20-30%) for 1 minute before adding raw material. Avoid 100% full-power preheating, as rapid temperature rise can cause trapped moisture to expand violently and crack the crucible.

Q10: For large raw materials, can I remove the stopper rod and add material while melting?

A: This is possible for high-purity metals like pure gold, silver, or copper. However, it is not recommended for alloys or K-gold. These materials have poorer fluidity, and without the stopper rod to control the flow, a small amount of residual metal may not have enough gravitational force to overcome its own viscosity, leading to material loss and incomplete drainage.

Q11: What is the minimum amount of material required for granulation?

A: The material weight must reach at least one-third (1/3) of the crucible’s capacity. Insufficient material will not generate enough gravitational force for complete drainage, resulting in residue and loss.

Q12: Is it necessary for me to buy a vacuum granulator?

A: For melting pure gold and pure silver, a vacuum system is typically not necessary. These high-purity precious metals are inherently resistant to oxidation, and our machines are equipped with an inert gas protection system (Argon/Nitrogen) that flows throughout the process.

A vacuum granulator is highly recommended for alloys like K-gold or 925 silver to minimize oxidation and ensure high-quality granules. However, as vacuum machines are more expensive, the choice depends on your specific production needs and budget. We strongly advise consulting with our technical engineers before purchasing to determine the best solution for you.

Graphite crucible can be customized to suit different needs, the porous design of the bottom acts as a crusher to cast the molten metal into pellets

The integrated design of the power cabinet and furnace facilitates operation and mobility and reduces space requirements

Argon gas to protect the metal from oxidation during the melting process, and the finished product is bright and free of impurities

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST metal granulator

Contact Our Engineer Team

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….