- Call Us: 008615168765707

- Mail Us: [email protected]

If you are looking for the Vacuum centrifugal casting machine? Inquiry Now

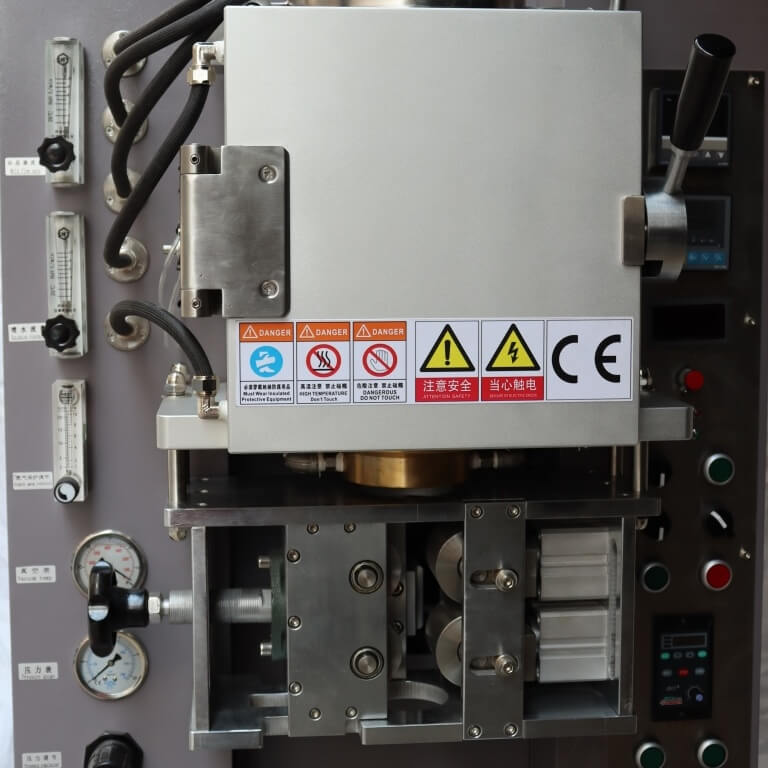

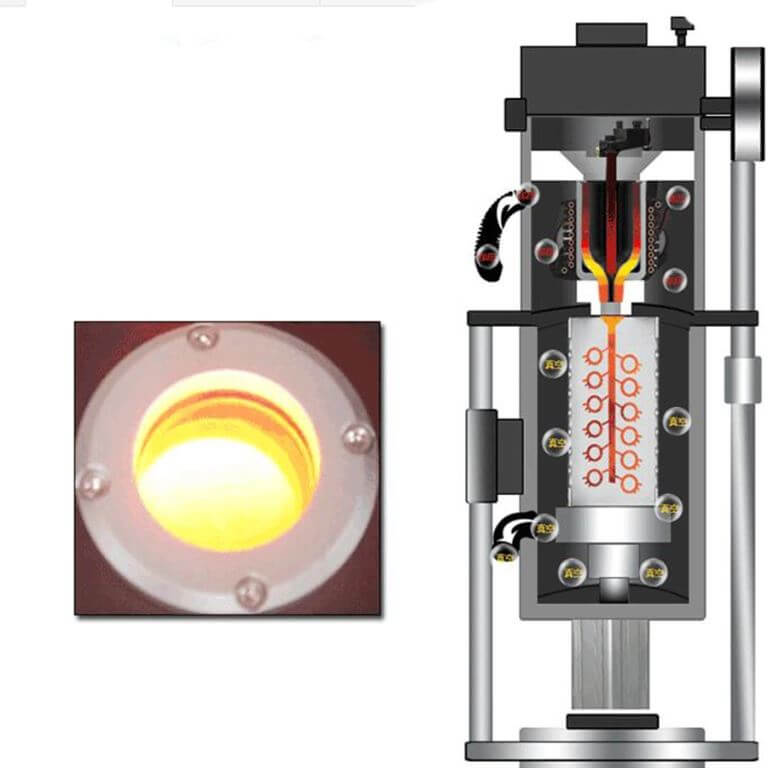

This Centrifugal Vacuum Casting Machine adopts the latest Japanese crystal intermediate frequency generator, the output power is continuously adjustable, the oscillation frequency is stable with working ability of 24 hrs continuously working.

The centrifugal motor adopts a quick-start motor which can be driven immediately when the machine starts. It can reach the maximum speed in 0.2 seconds, and the speed is continuously adjustable.

CDOCAST centrifugal casting machine is equipped with perfect protection functions, including overvoltage, overheating, and water shortage protection. The switch is designed with mutual locking to prevent misoperation. Special pulse step function, mixing evenly and casting automatically, ensuring uniform product quality

CDOCAST centrifugal vacuum casting machine is specially designed for small-volume platinum, palladium, and stainless steel casting, this centrifugal casting machine comes with a vacuum pump design, thus the whole casting process will be in a vacuum condition, which can minimize the oxidation of the metal, When the charge is molten, the coil is retracted and the arm starts to spin in a high speed. During the rotating process, the metal gets out from the crucible and enters the flask.

This centrifugal vacuum casting machine is very suitable for small-volume platinum, palladium, and stainless steel casting. The maximum casting weight is 500g. Of course, we can also customize other platinum-casting machines.

In case you are interested in getting a quotation for a non-standard casting machine do not hesitate to send us your technical specifications

| Model | CDO-CE15 | CDO-CE20 |

| Power | 15kw | 20kw |

| Voltage | 3P, 380V, 50/60Hz | 3P, 380V, 50/60Hz |

| Applicable metal | Platinum / Palladium / Steel / Stainless steel | |

| Melting time | 1-3 min | 2-3 min |

| Max capacity | 300g / 500g (platinum) | 1kg (stainless steel) |

| Max temperature | 2000℃ | 2000℃ |

| Overall Size | 1026*1017*1040mm | 1294*1267*1130mm |

| Weight | 230kg | 450kg |

Feature of centrifugal vacuum casting machine:

Q1. Which metal materials is this Vacuum Centrifugal Casting Machine suitable for?

A: This machine is specifically designed for casting high-grade jewelry and is perfectly suited for various precious metals and alloys, including stainless steel, platinum, palladium, Karat gold, and silver.

Q2. What is the maximum melting capacity of this Vacuum Centrifugal Casting Machine, and what is the flask size?

A: The designed capacity range for this machine is between 300 grams and 1 kilogram, making it highly suitable for small to medium-batch jewelry production.

The common standard flask size is φ 3.5 x 4 inches. To accommodate diverse production needs, we support customization of other, larger flask sizes, such as φ 5 x 7 inches.

Please refer to the specification parameters for specific machine models for precise capacity, or inquire about custom machine options.

Q3. What is the working principle of the Vacuum Centrifugal Casting Machine?

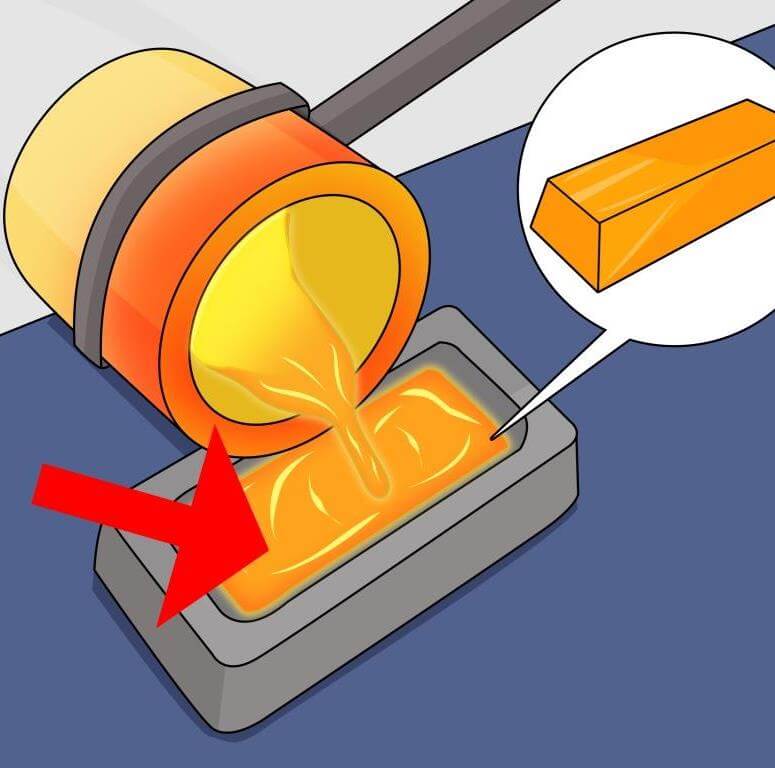

A: Vacuum Centrifugal Casting involves conducting both the metal melting and pouring processes within a vacuum chamber. Subsequently, centrifugal force generated by high-speed rotation propels the molten metal from the crucible at high velocity, forcing it to fill every intricate detail of the investment mold, ensuring sharp definition and defect-free castings.

Q4. What are the main advantages of the Centrifugal Casting Machine compared to other methods like Vacuum Pressure Casting?

A: *Superior Mold Filling Power and Feeding Capability: Centrifugal casting holds a natural advantage for components requiring extreme density and superior mechanical properties.

*Ideal for Highly Reactive and High-Melting-Point Metals: Such as platinum, palladium, and stainless steel.

*Higher Casting Purity, Better Inclusion Control: Due to density differences, inclusions tend to be pushed towards the casting’s inner surface by centrifugal force, making them easier to remove during subsequent machining.

*Smoother Mold Filling, Lower Risk of Gas Entrapment: The laminar flow filling characteristic of centrifugal casting promotes smooth surfaces and minimizes gas porosity in the castings.

Q5. What level of vacuum can this Centrifugal Casting Machine achieve? Is the rotation speed adjustable?

A: The machine utilizes a #100 type vacuum pump, capable of achieving a vacuum level of 0.1 MPa. The maximum rotation speed is steplessly adjustable from 0-700 rpm.

Q6. Is this Centrifugal Casting Machine equipped with temperature control and a touchscreen system?

A: Infrared temperature measurement control and a Siemens PLC touchscreen control system are available as optional features.

Q7. How long does it take to produce one batch with this Centrifugal Casting Machine?

A: It is equipped with a latest-generation Japanese transistorized medium-frequency generator with continuously adjustable output power, this centrifugal casting machine achieves high production efficiency of 4-5 minutes per batch (melting time approximately 1-3 minutes, centrifugal casting time approximately 1-2 minutes).

Q8. Besides the casting machine itself, what other equipment do I need for operation?

A: Yes, you will also need a water chiller, an air compressor, and an inert gas supply:

Water Chiller: Required for cooling the machine’s induction coil to prevent overheating. Water pressure requirement is ≥ 0.2 MPa.

Air Compressor: Needed for the automated opening and closing of the machine lid. Required air pressure range: 0.4 – 0.8 MPa.

Inert Gas: Argon or Nitrogen can be used.

Q9. What consumables are required for this Centrifugal Casting Machine, and what is their typical service life?

A: The main consumables for this machine are quartz crucibles, investment powder, and flasks. Quartz crucibles are fragile items subject to high wear; their typical service life is around 2-5 uses. The specific service life depends on the customer’s operating environment and daily maintenance practices.

Q10. Why is vacuum application necessary before casting? What is its purpose?

A: Applying vacuum serves two core purposes:

① Prevents Metal Oxidation: Precious metals in a molten state are highly reactive and readily form oxide slag when exposed to oxygen, compromising casting quality and aesthetics. The vacuum environment eliminates this issue.

② Removes Gases from the Plaster Mold: Evacuating the air removes gases trapped within the investment mold surrounding the wax tree, ensuring the molten metal perfectly replicates the finest details and avoiding gas porosity in the final castings.

Q11. How should castings be cleaned and handled after the casting process is complete?

A: After casting is finished, use tongs to remove the flask. Then, submerge the entire flask in water for “quench cleaning.” The investment mold will disintegrate upon contact with water, revealing the casting tree inside. Finally, cut the individual castings from the sprue and proceed with subsequent finishing steps, like polishing.

Q12. What are the key maintenance points for this Centrifugal Casting Machine?

A: *Cleaning: After each use, thoroughly clean any spilled metal debris and investment material, especially from the centrifugal arm and bearing areas.

*Consumable Replacement: Monitor the condition of quartz crucibles and replace them promptly when needed.

*Vacuum Pump: Regularly check the vacuum pump oil level and oil condition. Change the oil according to the manufacturer’s schedule to maintain specified vacuum levels.

*Rotating Components: Periodically inspect the balance of the rotation arm and the flexibility of the release mechanism. Lubricate bearings as appropriate.

*Electrical System: Keep the equipment dry and clean. Regularly inspect power cords and connections.

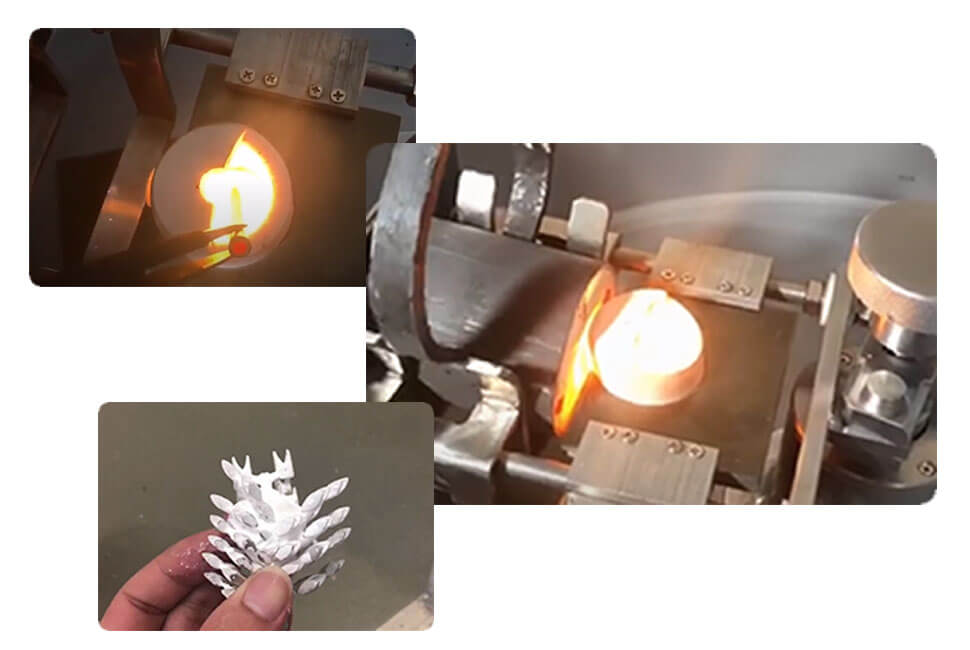

Centrifugal vacuum casting machine coil rise and fall controlled by operation panel

After metal completely melted in a vacuum, the metal comes out of the crucible by spinning and into the flask.

Specially designed for small volume platinum, palladium, stainless steel casting

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Vacuum centrifugal casting machine

Contact Our Engineer Team

CDOCAST Jewelry Continuous Casting Machine For making jewelry into wire, rod , plate

FAQ On Precious Metal Melting Furnace Purchase- Here you can find all the answers to the questions when you purchase precious metl casting machine

Video of Jewelry Vacuum Pressurized Casting Machine, you can learn more how the jewelry is cast

Platinum Centrifugal Casting Machine -Vacuum Centrifugal casting for platinum ,steel,& stainless steel