- Call Us: 008615168765707

- Mail Us: [email protected]

The most popular vacuum gold bar making machine for sale, Inquiry Now!

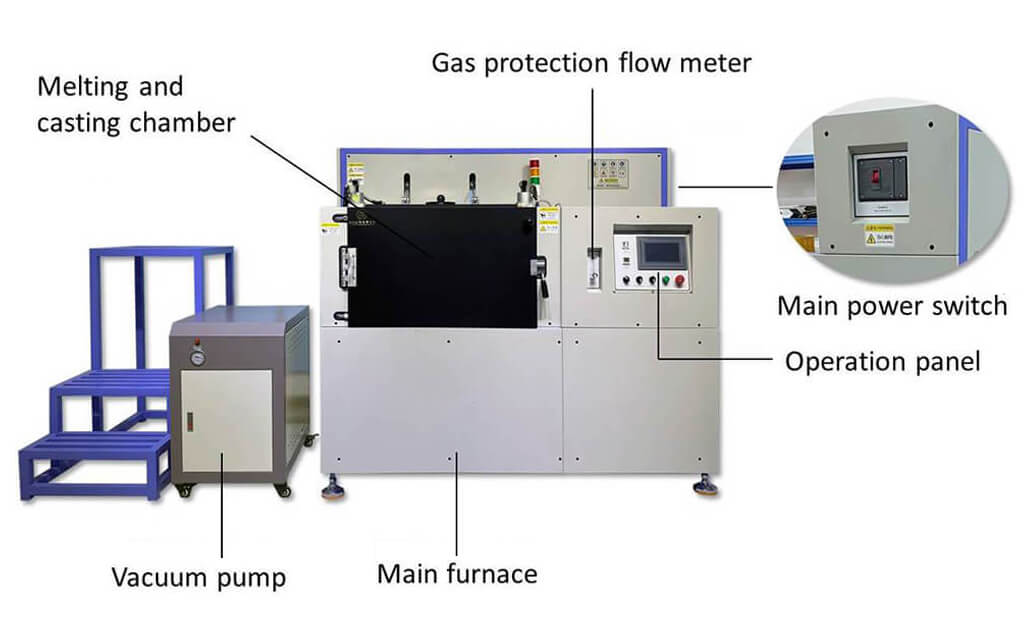

In the world of precious metals, every gram counts. CDOCAST’s advanced vacuum Gold Silver Bar casting machines are engineered for those who demand perfection — delivering flawless, high-purity gold and silver bars with uncompromised surface quality and minimal metal loss.

Whether you’re producing investment-grade bars or custom ingots, the CDOCAST vacuum gold bar casting machine offers unmatched flexibility and precision.

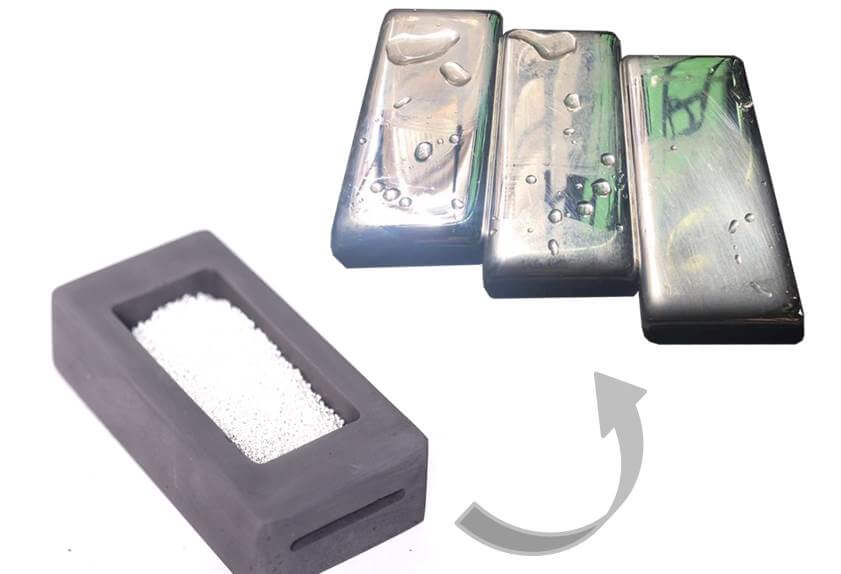

Batch Capacity: Cast up to 4 x 1kg ingots per cycle or a single 15kg large bullion bar. Custom sizes are also supported.

Vacuum + Argon Protection: Melt and cast in an oxygen-free environment to eliminate oxidation, porosity, and surface defects such as water ripples.

Maximized Yield: With near-zero precious metal loss, our systems help protect your margins and enhance metal recovery.

Scalable Power: From 75kW for standard 15kg bars to custom configurations — the right power for your output needs.

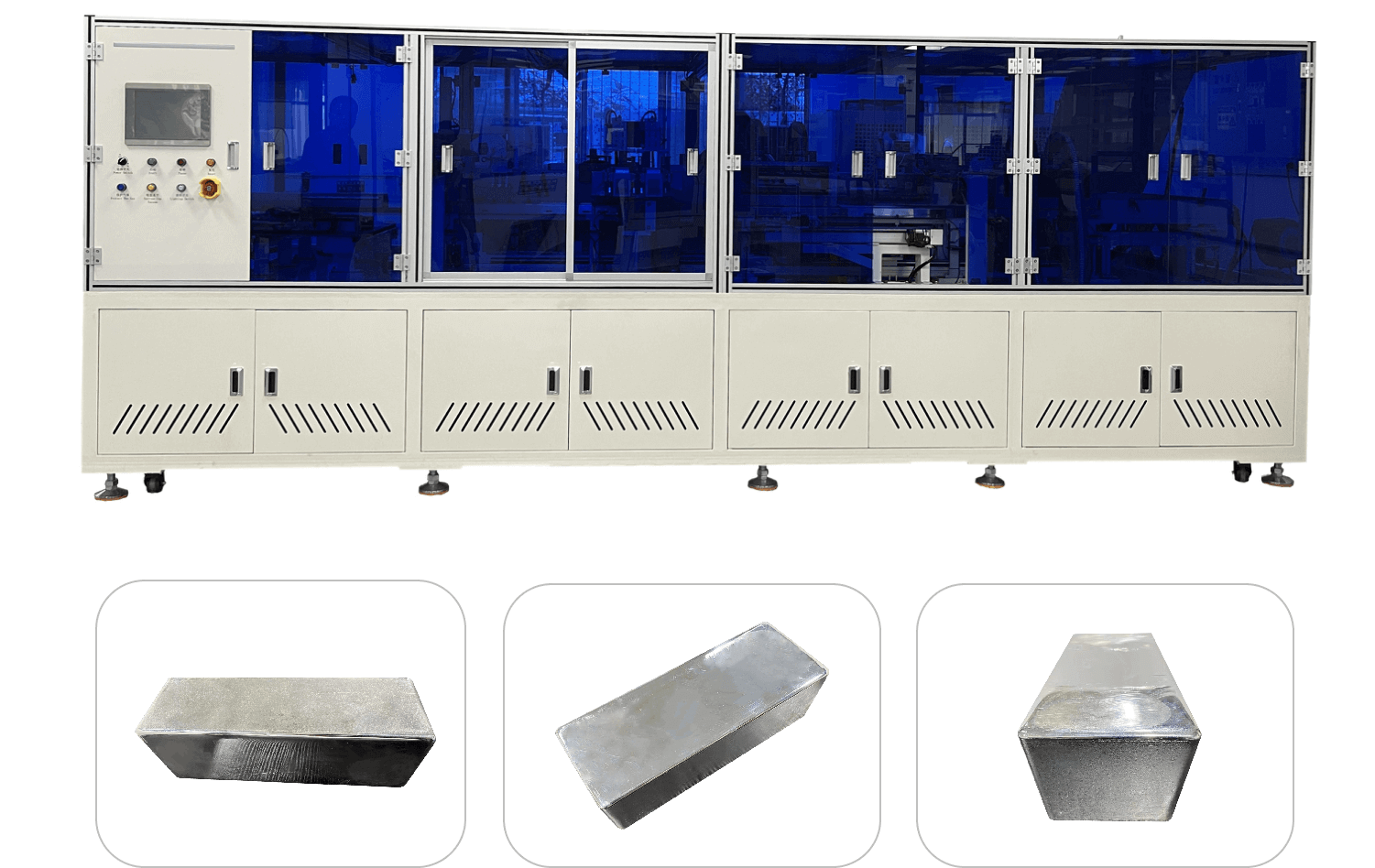

Produce mirror-finish silver bars that stand out in the market. CDOCAST’s silver bullion vacuum casting machines combine German IGBT induction technology with high-vacuum performance for industrial-grade reliability.

Multi‑Size Output: Cast 1kg, 5kg, 15kg, 30kg, or 1000oz bars in every batch.

Power‑Driven Efficiency: Choose from 25kW to 90kW models — a 90kW unit produces three 5kg silver bars per cycle.

High‑Vacuum Pumps: Equipped with German‑imported vacuum pumps to ensure brilliant surface quality and higher density.

Rapid Cycle Times: Melt in 6–15 minutes, cool in 8–15 minutes — produce 10kg of silver bars in under 25 minutes per cycle.

High‑Life Graphite Molds: Each custom mold lasts 200+ casting cycles, reducing downtime and tooling costs.

Energy‑Efficient Operation: Advanced induction heating ensures stable performance with lower operating costs.

Global Client Trust: Trusted by mints, refineries, and precious metal producers worldwide for performance-driven bullion solutions.

Whether you’re expanding production or launching a new bullion product line, CDOCAST delivers the technology, reliability, and finish that investors recognize and respect.

CDOCAST — Where Innovation Meets Precious Metals Mastery

Why Industry Leaders Choose CDOCAST:

– *Intuitive Operation: Minimal training required for expert-level results

– *Consistent Quality: Perfectly finished bars with mirror-like surfaces

– *Durable Performance: Engineered for long-term reliability

– *Rapid ROI: High throughput with minimal operational overhead

*Ready to transform your bullion production? Contact our engineering team to discover how our vacuum casting solutions can elevate your operation.

Click here to watch the video»

Click here to watch the video»

-2.jpg)

Click here to watch the video»

Click here to watch the video»

| Model number | CDO-F1 | CDO-F2 | CDO-F4 |

| Power source | Three phase 380V±10%, 50/60Hz | Three phase 380V±10%, 50/60Hz | Three phase 380V±10%, 50/60Hz |

| Power | 25kw | 35kw | 45kw |

| Control system | PLC/Manual | PLC/Manual | PLC/Manual |

| Applicable metal | Gold and silver | Gold and silver | Gold and silver |

| Melting time | About 6 mins | About 7 mins | About 7-8 mins |

| Casting time | About 6-7 mins | About 7-8 mins | About 7-10 mins |

| The Max capacity | 1 pc 1 kg bar | 2 pcs 1 kg bar | 4 pcs 1 kg bar |

| Dimension | 950*750*1070mm | 1100*880*1100mm | 1520*900*1080mm |

| Weight | About 200 kg | About 300 kg | About 550 kg |

| Protective gas | Nitrogen or argon | Nitrogen or argon | Nitrogen or argon |

| Vacuum pump | 40 m³/hour | 40 m³/hour | 40 m³/hour |

| Heating technology | Induction heating | Induction heating | Induction heating |

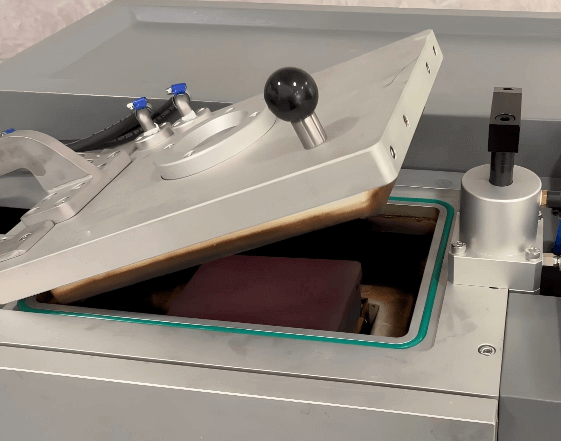

| Auto lid opening and closing | Yes | Yes | Yes |

Experience the next generation of precision casting technology with CDOCAST’s advanced vacuum bullion machines. Engineered for both exceptional results and remarkable ease of use, our systems transform raw materials into market-ready gold and silver bars with unmatched efficiency.

1. Seamless Automation from Start to Finish

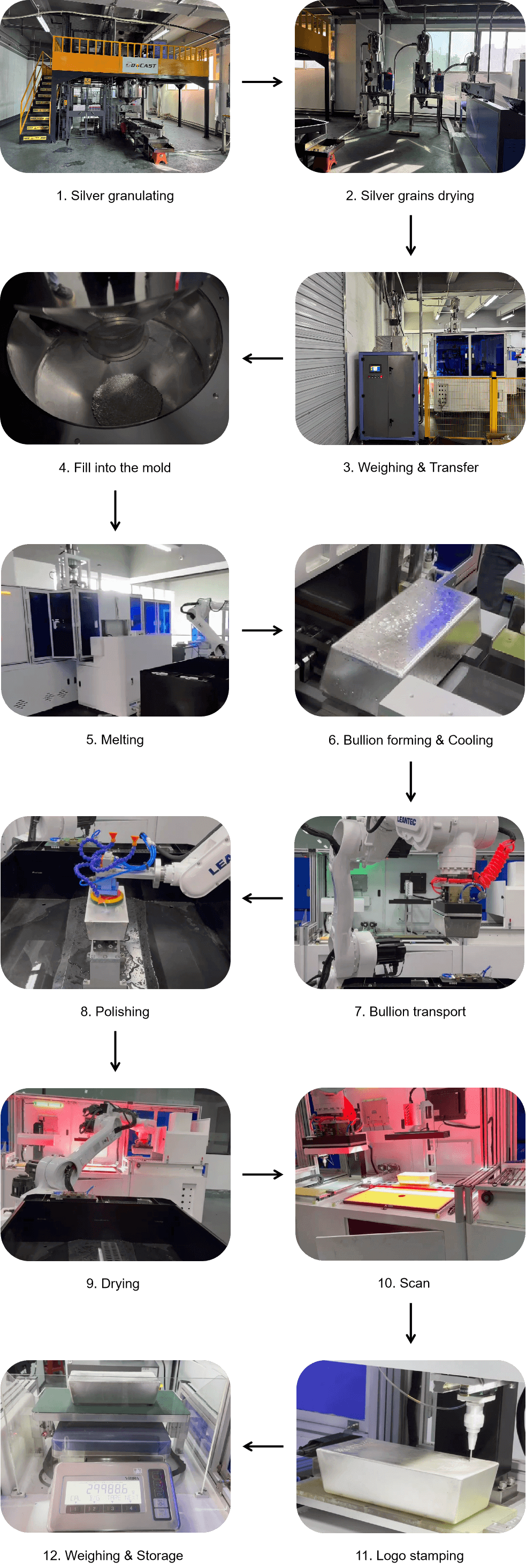

Our PLC touch screen interface puts complete control at your fingertips. Simply load pre-weighed material into the graphite mold, secure the chamber door, and press start. The system executes a fully automated cycle, delivering perfectly cast bars with zero manual intervention.

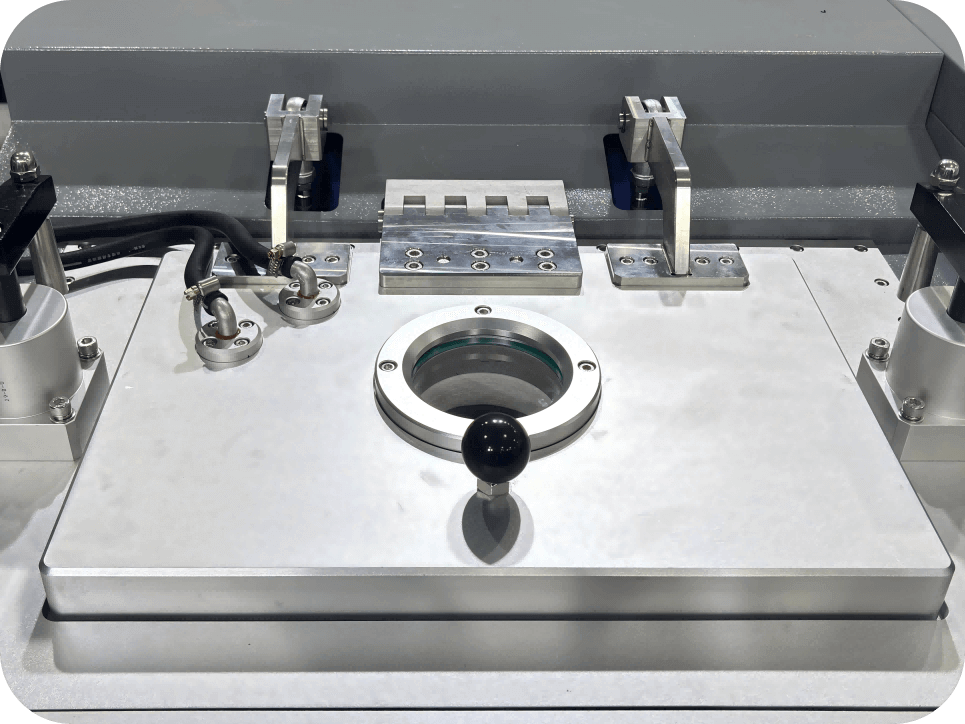

2. Advanced Thermal Management for Superior Surface Quality

Featuring custom-shaped induction coils with integrated cooling technology, our proprietary process ensures uniform temperature distribution. The intelligent cooling system actively regulates mold temperature throughout the cycle, producing consistently brilliant, flawlessly flat surfaces that meet the highest market standards.

3. Optimized Production Cycles for Maximum Efficiency

Each casting sequence combines precisely calibrated melting and cooling phases. With melting cycles of 6-12 minutes and optimized cooling protocols, we balance production speed with mold longevity – delivering superior throughput while protecting your investment in tooling.

4. Engineered for Continuous Industrial Performance

Built for round-the-clock operation, our machines maintain consistent performance under demanding production schedules. The robust construction and refined thermal management ensure reliable output for high-volume manufacturing environments.

5. Self-Sufficient Installation and Operation

Forget complex onsite engineering. Every system includes comprehensive video guidance for installation and commissioning. Each unit undergoes rigorous factory testing, arriving ready to produce quality results from day one

6. Confidence-Backed Warranty Protection

We stand behind every system with a comprehensive Two-year warranty, ensuring your complete peace of mind and investment security.

Unveiling How Our Cooling System Achieves a Mirror Effect on the Bar

| Component | Other Companies | CDOCAST |

|

Control Panel |

Unbranded touchscreen with unresponsive controls over time and no quality assurance.

|

Imported Siemens touchscreen & PLC control system for full automation and durability. Casting data can be viewed, saved, and adjusted directly on the screen.

|

|

Indicator Light |

No status lights. |

Clear visual status indicators for standby, operation, and alarm modes.

|

|

Mold Size |

1kg mold: 135*72.5mm |

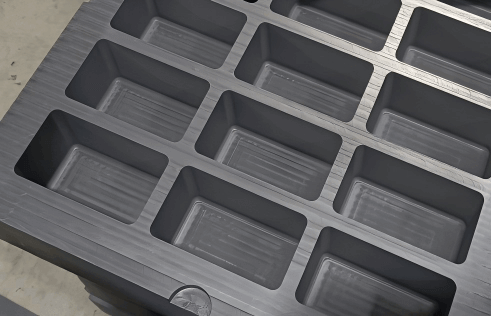

Larger cooling plates enable bigger mold sizes: 1kg mold: 176*90mm 4kg mold: 280*144mm Substantially higher casting capacity |

|

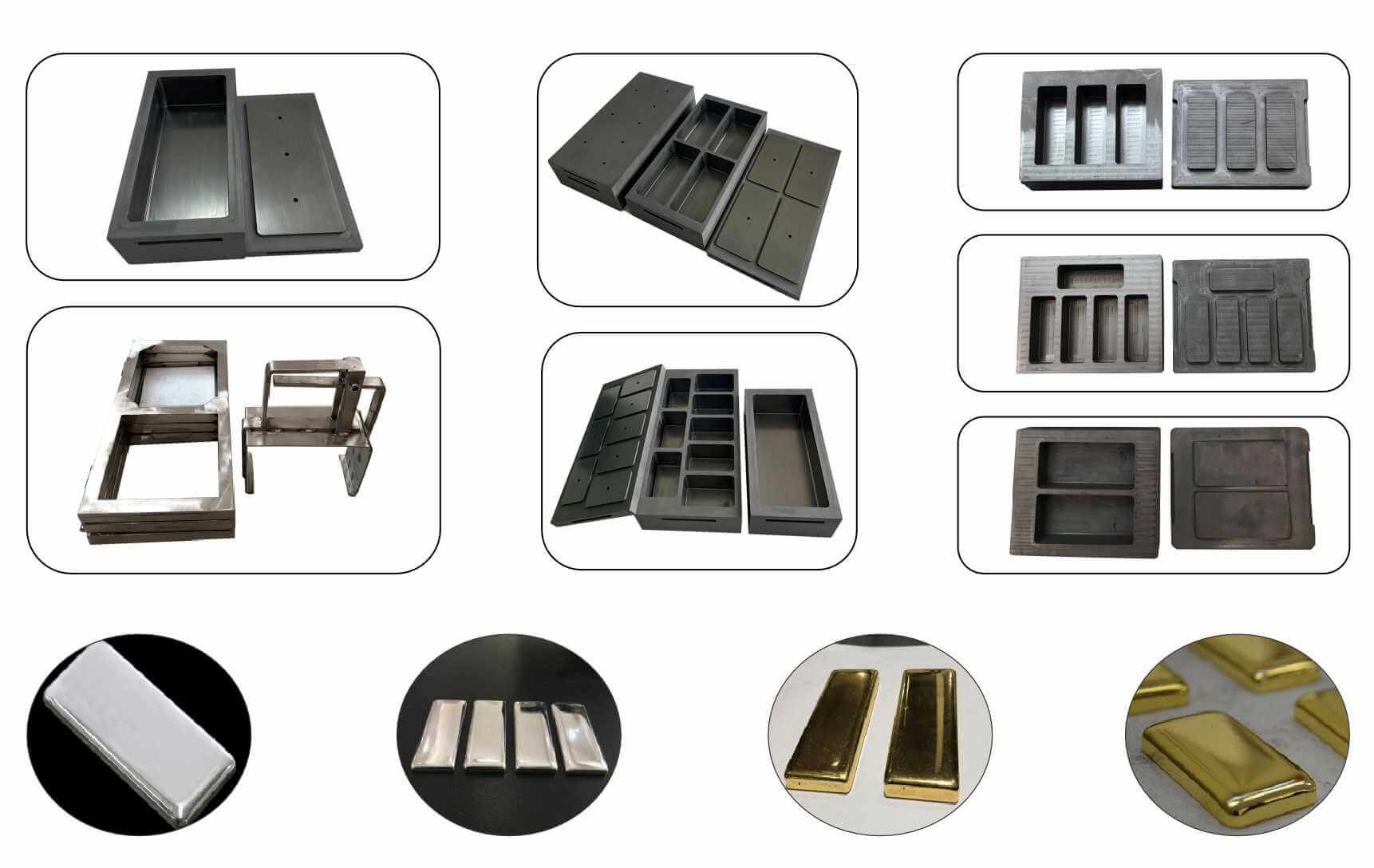

Graphite Mold |

Lower grade graphite (e.g., -5), inexpensive but prone to damage, requiring frequent replacement |

High purity -6 grade graphite: Superior hardness, elasticity, and compression resistance → Highly durable and heat-resistant.

|

|

Lid |

Manual opening, labor-intensive. |

Fully automated pneumatic lid for effortless operation.

|

|

Machine Housing |

Welded assembly with standard paint that chips easily. |

High-purity, one-piece aluminum casing – lightweight with excellent heat dissipation. Heat-resistant baked enamel finish for superior aesthetics & durability.

|

|

Spare Parts |

Standard domestic or refurbished components. |

Premium imported parts: Siemens touchscreens, Infineon IGBT modules (Germany), power boards, etc. |

|

Thermocouple |

Standard Type K, max temperature 1300°C, easily damaged. |

Specialized Type S/R for precious metals, withstands up to 1600°C, high quality and reliability

|

|

Vacuum Pump |

Typically 63m³/h pumps without safety enclosures, posing risks. Some use small built-in pumps with poor vacuum results & difficult repair. |

Powerful 100m³/h pump for flawless, dense castings without pores. Includes safety enclosure & easy to read pressure gauge.

|

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation

A: We use only high-density, premium graphite blocks to craft our molds, ensuring superior durability compared to standard market options. Under normal operating conditions, each mold is guaranteed for 200+ casting cycles without loss of quality

A: All CDOCAST machines include a 2-year comprehensive warranty. During this period, we begin with free remote video diagnostics. If any components are faulty, we replace them at no cost. Should the machine fail due to manufacturing defects, we offer a full machine replacement—free of charge.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: Melting typically takes 6–8 minutes, depending on bar size and material. For a standard 1kg gold or silver bar, melting is complete in about 6 minutes. We recommend a minimum 8-minute cooling phase—longer cooling not only ensures better surface finish but also extends your mold’s service life.

A: A brilliant, mirror-like surface requires high-purity material—at least 99.9% fine gold or silver. Lower purity levels will result in a less reflective finish and may affect overall bar appearance.

A: Yes—as long as your chiller meets our technical specifications for flow rate and temperature control, you’re welcome to use it. We also offer compatible CDOCAST water chillers optimized for our systems.

A: We offer hydraulic pressing systems capable of imprinting custom designs, logos, or text onto bars. Additionally, we provide casting Bar die design and production services. For serial numbering or fine markings, we supply laser marking or logo stamping machines tailored to your needs.

A: Several technical factors—such as mold temperature, cooling rate, or material purity—can affect surface finish. Our technical team has prepared an in-depth article detailing common issues and solutions

A: Yes. We recommend using argon or nitrogen for optimal oxidation prevention during melting. The gas flow is program-controlled and activated only at critical stages—not continuously—ensuring efficiency and cost-effectiveness. Typical consumption ranges between X L/min and Y L/min, depending on bar size and process phase.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: We use only high-density, premium graphite blocks to craft our molds, ensuring superior durability compared to standard market options. Under normal operating conditions, each mold is guaranteed for 200+ casting cycles without loss of quality.

A: All CDOCAST machines include a 2-year comprehensive warranty. During this period, we begin with free remote video diagnostics. If any components are faulty, we replace them at no cost. Should the machine fail due to manufacturing defects, we offer a full machine replacement—free of charge.

A: Melting typically takes 6–8 minutes, depending on bar size and material. For a standard 1kg gold or silver bar, melting is complete in about 6 minutes. We recommend a minimum 8-minute cooling phase—longer cooling not only ensures better surface finish but also extends your mold’s service life.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: A brilliant, mirror-like surface requires high-purity material—at least 99.9% fine gold or silver. Lower purity levels will result in a less reflective finish and may affect overall bar appearance.

A: Yes—as long as your chiller meets our technical specifications for flow rate and temperature control, you’re welcome to use it. We also offer compatible CDOCAST water chillers optimized for our systems.

A: We offer hydraulic pressing systems capable of imprinting custom designs, logos, or text onto bars. Additionally, we provide casting Bar die design and production services. For serial numbering or fine markings, we supply laser marking or logo stamping machines tailored to your needs.

A: Several technical factors—such as mold temperature, cooling rate, or material purity—can affect surface finish. Our technical team has prepared an in-depth article detailing common issues and solutions:

[Click the Link to the Technical Article Here]

A: No. Platinum and palladium have significantly higher melting points and require specialized furnace engineering. We recommend our Tilting-Type Vacuum Bar Casting Furnace, specifically designed for high-temperature precious metals. Learn more here:

[Click the Link to Tilting Furnace Product Page]

A: Yes. We recommend using argon or nitrogen for optimal oxidation prevention during melting. The gas flow is program-controlled and activated only at critical stages—not continuously—ensuring efficiency and cost-effectiveness. Typical consumption ranges between X L/min and Y L/min, depending on bar size and process phase.

A: No. Platinum and palladium have significantly higher melting points and require specialized furnace engineering. We recommend our Tilting-Type Vacuum Bar Casting Furnace, specifically designed for high-temperature precious metals. Learn more here:

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: We use only high-density, premium graphite blocks to craft our molds, ensuring superior durability compared to standard market options. Under normal operating conditions, each mold is guaranteed for 200+ casting cycles without loss of quality.

A: All CDOCAST machines include a 2-year comprehensive warranty. During this period, we begin with free remote video diagnostics. If any components are faulty, we replace them at no cost. Should the machine fail due to manufacturing defects, we offer a full machine replacement—free of charge.

A: Melting typically takes 6–8 minutes, depending on bar size and material. For a standard 1kg gold or silver bar, melting is complete in about 6 minutes. We recommend a minimum 8-minute cooling phase—longer cooling not only ensures better surface finish but also extends your mold’s service life.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: A brilliant, mirror-like surface requires high-purity material—at least 99.9% fine gold or silver. Lower purity levels will result in a less reflective finish and may affect overall bar appearance.

A: Yes—as long as your chiller meets our technical specifications for flow rate and temperature control, you’re welcome to use it. We also offer compatible CDOCAST water chillers optimized for our systems.

A: We offer hydraulic pressing systems capable of imprinting custom designs, logos, or text onto bars. Additionally, we provide casting Bar die design and production services. For serial numbering or fine markings, we supply laser marking or logo stamping machines tailored to your needs.

A: Several technical factors—such as mold temperature, cooling rate, or material purity—can affect surface finish. Our technical team has prepared an in-depth article detailing common issues and solutions:

[Click the Link to the Technical Article Here]

A: No. Platinum and palladium have significantly higher melting points and require specialized furnace engineering. We recommend our Tilting-Type Vacuum Bar Casting Furnace, specifically designed for high-temperature precious metals. Learn more here:

[Click the Link to Tilting Furnace Product Page]

A: Yes. We recommend using argon or nitrogen for optimal oxidation prevention during melting. The gas flow is program-controlled and activated only at critical stages—not continuously—ensuring efficiency and cost-effectiveness. Typical consumption ranges between X L/min and Y L/min, depending on bar size and process phase.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: We use only high-density, premium graphite blocks to craft our molds, ensuring superior durability compared to standard market options. Under normal operating conditions, each mold is guaranteed for 200+ casting cycles without loss of quality.

A: All CDOCAST machines include a 2-year comprehensive warranty. During this period, we begin with free remote video diagnostics. If any components are faulty, we replace them at no cost. Should the machine fail due to manufacturing defects, we offer a full machine replacement—free of charge.

A: Melting typically takes 6–8 minutes, depending on bar size and material. For a standard 1kg gold or silver bar, melting is complete in about 6 minutes. We recommend a minimum 8-minute cooling phase—longer cooling not only ensures better surface finish but also extends your mold’s service life.

A: Yes. Every machine is accompanied by comprehensive bilingual (English and Chinese) manuals, featuring detailed step-by-step guides for straightforward installation and commissioning. Should you require technical assistance, we can dispatch our engineers for on-site support at a service fee of USD 150 per day, exclusive of flight tickets, visa arrangements, and accommodation.

A: A brilliant, mirror-like surface requires high-purity material—at least 99.9% fine gold or silver. Lower purity levels will result in a less reflective finish and may affect overall bar appearance.

A: Yes—as long as your chiller meets our technical specifications for flow rate and temperature control, you’re welcome to use it. We also offer compatible CDOCAST water chillers optimized for our systems.

A: We offer hydraulic pressing systems capable of imprinting custom designs, logos, or text onto bars. Additionally, we provide casting Bar die design and production services. For serial numbering or fine markings, we supply laser marking or logo stamping machines tailored to your needs.

A: Several technical factors—such as mold temperature, cooling rate, or material purity—can affect surface finish. Our technical team has prepared an in-depth article detailing common issues and solutions:

[Click the Link to the Technical Article Here]

A: No. Platinum and palladium have significantly higher melting points and require specialized furnace engineering. We recommend our Tilting-Type Vacuum Bar Casting Furnace, specifically designed for high-temperature precious metals. Learn more here:

[Click the Link to Tilting Furnace Product Page]

A: Yes. We recommend using argon or nitrogen for optimal oxidation prevention during melting. The gas flow is program-controlled and activated only at critical stages—not continuously—ensuring efficiency and cost-effectiveness. Typical consumption ranges between X L/min and Y L/min, depending on bar size and process phase.

The Vuum Bar Making Machine is equipped with an automatic cover opening and closing device, which does not require manual opening and closing of the furnace cover. Easy and safe operation.

High Quality Graphite molds can be customized according to different bar size,and we have professional engineer team to provide the design drawing

After vacuum pressure casting,the products are with flat and shiny surface and density

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST gold bar making machine

Contact Our Engineer Team

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

FAQ On Precious Metal Melting Furnace Purchase- Buyer Guider To Help you buy the most suitable Furnace in precious metals

CDOCAST Vacuum gold bar Making machine video to help you learn more how our furnace is working.

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine