- Call Us: 008615168765707

- Mail Us: [email protected]

Are you looking for push out melting equipment in the market,YOU ARE RIGHT PLACE.

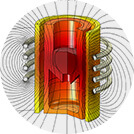

Push Out Metel Melting Equipment is a lifting metal melting furnace. It can lift the furnace body from the ground to a predetermined height through a lifting mechanism so that the crucible is completely located in the furnace body, and then heated and melted.

Discover the future of metal melting with our cutting-edge Push out Design Medium Frequency Melting Furnace—engineered for efficiency, safety, and unmatched performance. Designed for foundries, jewelers, and precision casting applications, this furnace combines advanced medium frequency induction technology with a unique bottom-release mechanism for seamless operation.

Push Out Metal Melting Equipment usually consists of a furnace body and a lifting mechanism. An induction coil is provided inside the furnace body. The furnace body is raised to a predetermined height through a lifting mechanism, and the crucible is heated to melt the metal. When the metal reaches the required temperature or is smelted, the lifting mechanism lowers it back to the ground.

The push out melting equipment has the advantages of high efficiency, high precision, and a high degree of automation. It is suitable for heating and smelting various metal materials, such as iron, steel, copper, aluminum, etc. In industrial production, it is widely used, especially in the steel and non-ferrous metal smelting industries.

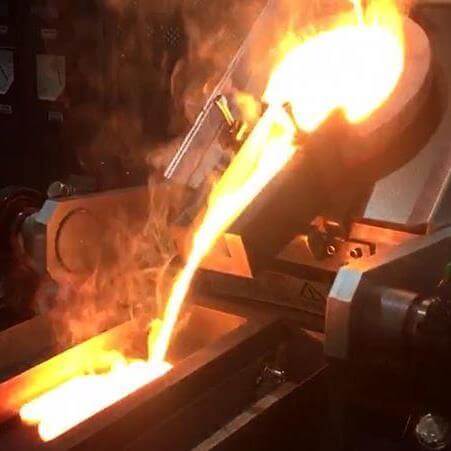

Our unique Push out structure sets us apart. By eliminating traditional tilting mechanisms, we minimize spill risks, improve operator safety, and ensure a smoother workflow. The automated exposure of the crucible streamlines the pouring process, making it ideal for high-frequency melting operations where speed and accuracy are critical.

Precision casting of jewelry, dental alloys, and decorative items.

Small to medium-scale foundries for non-ferrous metal production.

Research and development labs requiring consistent melting conditions.

| Model number | CDO-PO40 | CDO-PO45 | CDO-PO60 | CDO-PO70 |

| Applicable metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | |||

| Voltage | 3p, 380V, 50/60Hz | 3P, 380 V, 50/60Hz | 3P, 380 V, 50/60Hz | 3P, 380 V, 50/60Hz |

| Power | 40 Kw | 45 Kw | 60 Kw | 70 Kw |

| Capacity | 30KG silver | 50KG silver | 80KG silver | 100KG silver |

| Melting time | 10-20 min | 15-25 min | 10-20 min | 15-30 min |

| Dimension | Control box: 650*600*1300mm Furnace: 410*475*320mm |

Control box: 650*600*1300mm Furnace: 410*475*320mm |

Control box: 800*730*1560mm Furnace: 880*1100*2240mm |

Control box: 800*730*1560mm Furnace: 880*1100*2240mm |

| Max temperature | 1800℃ | 1800℃ | 1800℃ | 1800℃ |

| Weight | 500 KG | 560 KG | 680 KG | 700 KG |

Advanced Medium Frequency Induction Technology: Ensures rapid, uniform heating with exceptional energy efficiency, reducing melting times and operational costs.

Exclusive Bottom-Exit Design: After melting, the furnace body descends automatically, fully exposing the silicon carbide graphite crucible for easy access. No more risky tilting or manual handling!

Premium Silicon Carbide Graphite Crucible: Built to withstand extreme temperatures, ensuring longevity and consistent melting performance for non-ferrous metals like gold, silver, copper, and aluminum.

Crucible Tongs Integration: Designed to work seamlessly with crucible tongs, allowing operators to safely extract the crucible and pour molten metal directly into molds with precision.

Compact & Space-Saving: Ideal for facilities with limited space, this furnace delivers industrial-grade capacity without the bulk.

User-Friendly Control System: Intuitive interfaces enable precise temperature control and process automation, reducing human error and enhancing reproducibility.

CDOCAST Provide 2 Warranty time, and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST push out metal melting equipment

Contact Our Engineer Team

CDOCAST provide you types of Electric Melting Furnace for you to choose when you want to invest in the furnace.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

The chain tilting melting furnaces are designed with an automatic tilting mechanism, with a motor-driven chain to rotate the furnace which can ensure the tilting operation safe and stable

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….