- Call Us: 008615168765707

- Mail Us: [email protected]

The Most Advanced Laboratory Vacuum Induction Melting Furnace

*Ultimate Guide to Laboratory Vacuum Induction Melting Furnaces: Precision Engineering for Advanced Materials Research

*Introduction:

In the realm of materials science and metallurgical research, precision, control, and adaptability are paramount. Our laboratory vacuum induction melting furnace stands as a pinnacle of innovation, engineered to meet the rigorous demands of modern research and development. Designed for applications ranging from alloy development to advanced ceramics processing, this furnace combines cutting-edge technology with practical flexibility, making it an indispensable tool for academic institutions, industrial laboratories, and R&D facilities worldwide.

*Key Features and Benefits:

1. Versatile Capacity for Diverse Research Needs

– With a capacity range of 1kg to 10kg, our vacuum furnace accommodates both small-scale experiments and pilot production runs. This versatility ensures that researchers can efficiently process materials without compromising on precision or control. Whether you’re sintering metal powders, heat-treating alloys, or growing single crystals, this furnace delivers consistent results across a broad spectrum of applications.

2. Customizable Vacuum Systems for Precision Atmosphere Control

– The heart of any vacuum furnace lies in its ability to maintain a controlled environment. Our systems offer configurable vacuum pumping options to meet specific experimental requirements:

– Diffusion Pumps: Ideal for cost-effective high-vacuum applications, these pumps achieve vacuum levels suitable for most common metals and alloys.

– Molecular Pumps: For ultra-high vacuum environments (up to 10⁻⁸ mbar), molecular pumps are essential for processing oxygen-sensitive materials like titanium, nickel-based superalloys, and rare earth metals. This flexibility ensures that your research is never limited by atmospheric constraints.

3. Crucible Compatibility and Customization

▪ The choice of crucible material is critical to preventing contamination and achieving accurate results. Our furnace supports a wide range of crucible options, including:

▪ Silicon Carbide (SiC): Excellent thermal shock resistance and durability, ideal for high-temperature applications.

▪ Graphite: Perfect for non-oxide metals and alloys, offering superior thermal conductivity and stability.

▪ Zirconia (ZrO₂) and Magnesia (MgO): These refractory materials are suited for processing reactive metals and ceramics at extreme temperatures.

▪ Additionally, we offer custom-designed water-cooled copper molds for specialized applications such as rapid solidification, directional solidification, and unique geometric requirements.

4. Broad Material Applications

✔ Our vacuum furnace is designed to handle a diverse array of materials, including:

✔ Non-ferrous metals (e.g., aluminum, copper, and their alloys).

✔ Refractory metals (e.g., tungsten, molybdenum, and tantalum).

✔ Reactive metals (e.g., titanium, zirconium, and rare earth elements).

✔ Advanced ceramics and composites.

✔ The combination of precise temperature control and vacuum integrity ensures minimal contamination, making it possible to achieve high-purity results consistently.

5. User-Friendly Design and Robust Construction

– Built with researchers in mind, our furnace features an intuitive interface, programmable temperature cycles, and real-time monitoring capabilities. The robust construction ensures longevity and reliability, even under continuous operation. Safety features such as over-temperature protection, emergency cooling, and automated shutdown protocols are integrated to safeguard both the equipment and the user.

*Ideal Applications:

– Alloy Development and Testing: Perfect for homogenization, solution treatment, and aging studies.

– Sintering and Powder Metallurgy: Achieve uniform density and microstructure in powdered materials.

– Crystal Growth and Single Crystal Production: Precise temperature gradients and vacuum conditions enable the growth of high-quality crystals.

– Heat Treatment of Advanced Materials: From annealing to quenching, our furnace offers unparalleled control over thermal cycles.

– Academic and Industrial Research: Suitable for fundamental studies as well as applied research in aerospace, automotive, and energy sectors.

Click here to see the video link for the Laboratory Vacuum Induction Melting Furnace:

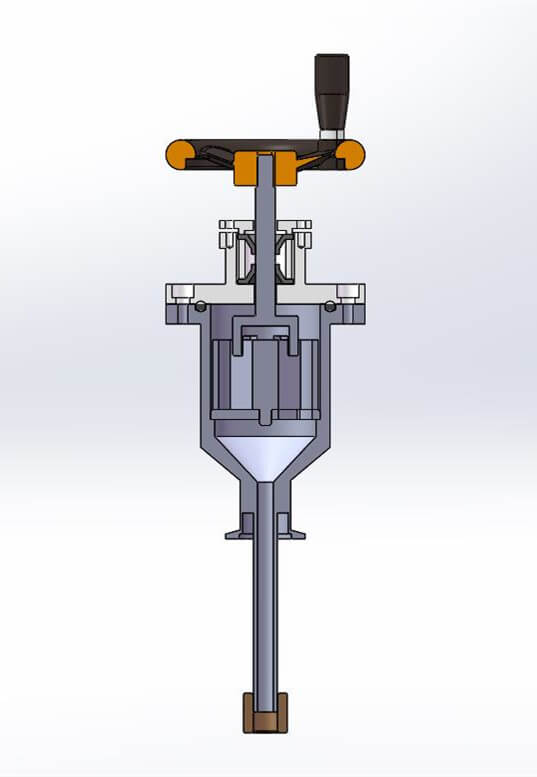

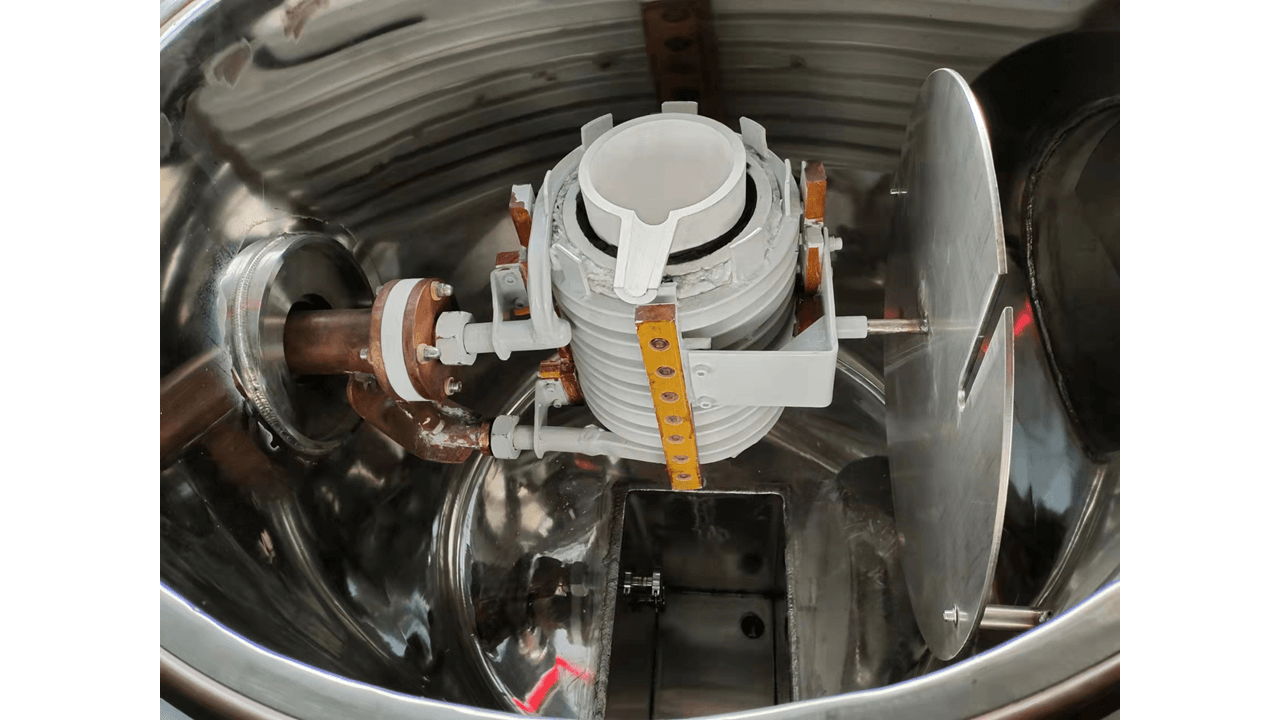

CDOCAST Vacuum Melting furnace can be equipped with a stirring device, which can stir materials at a uniform speed. The stirring rod is driven by a speed-regulating motor. Wilson or magnetic fluid and corrugated pipe are used to seal the stirring rod and furnace body. The stirring rod and motor can slide up and down freely under the drive of an electric moving screw rod, enter and leave the crucible.

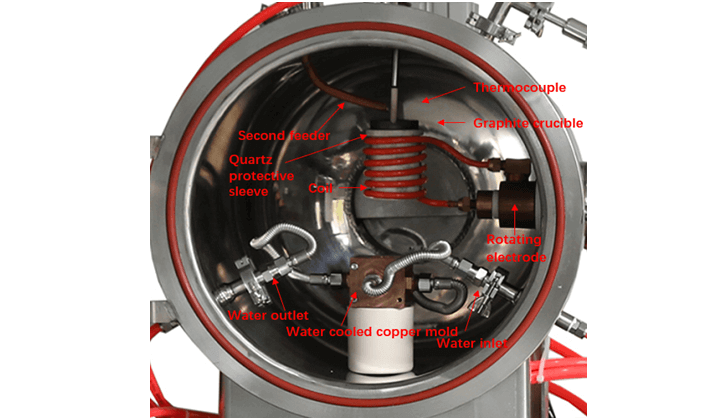

The secondary feeding device is designed to add various metal elements in the vacuum smelting process. Therefore, we will design a special 4-grid feeder hopper in the feeding device. The feeding device contains a lid, which can vacuum seal the feeding device. Before melting and vacuum pumping, put the metal elements in the hopper of the feeding device in advance. When feeding, rotate the hopper of the feeding device with the hand wheel, and the metal will flow out of the feeder mouth and into the molten metal level to avoid splashing.

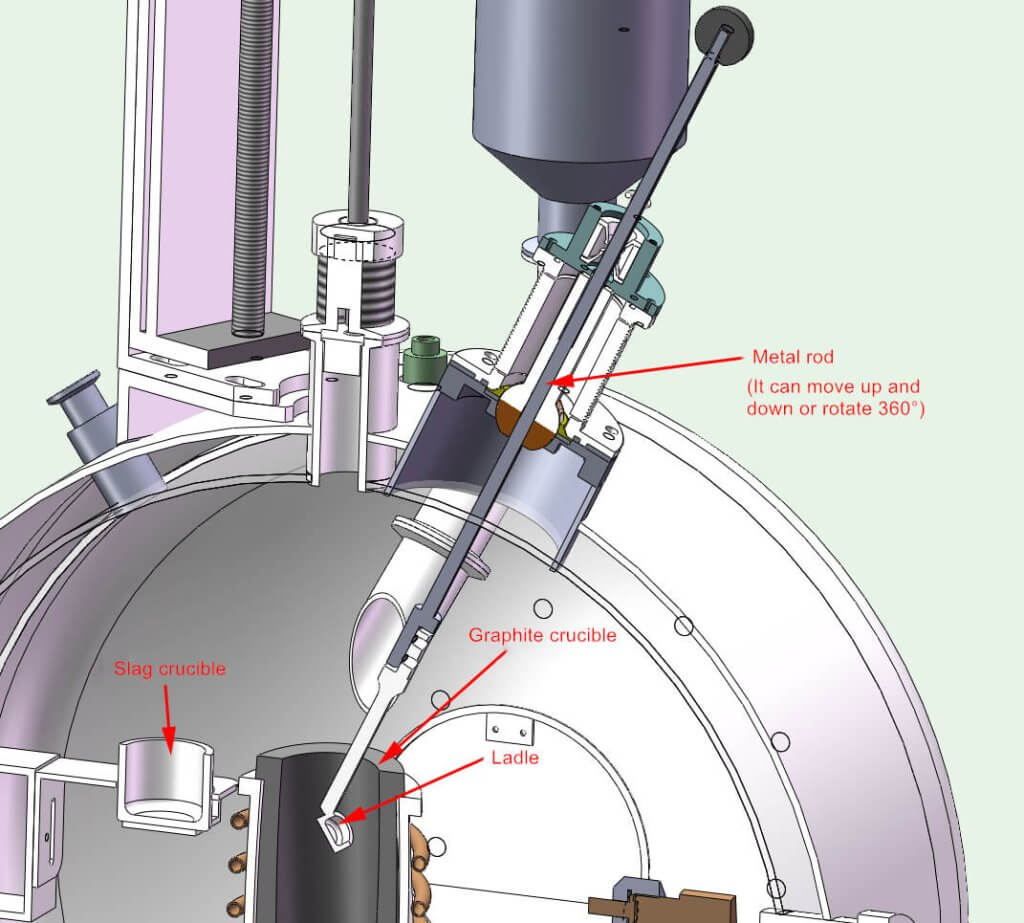

The slag raking device consists of a metal rod that can move up and down and rotate 360 degrees, a quartz spoon and a slag crucible. Use a quartz spoon to transfer the slag generated in the experiment to the slag crucible nearby.

There are many pieces of quartz glass in the observation window. You can rotate the contaminated quartz glass to one side and turn the clean glass to the observation hole to observe the melting of materials in the crucible.

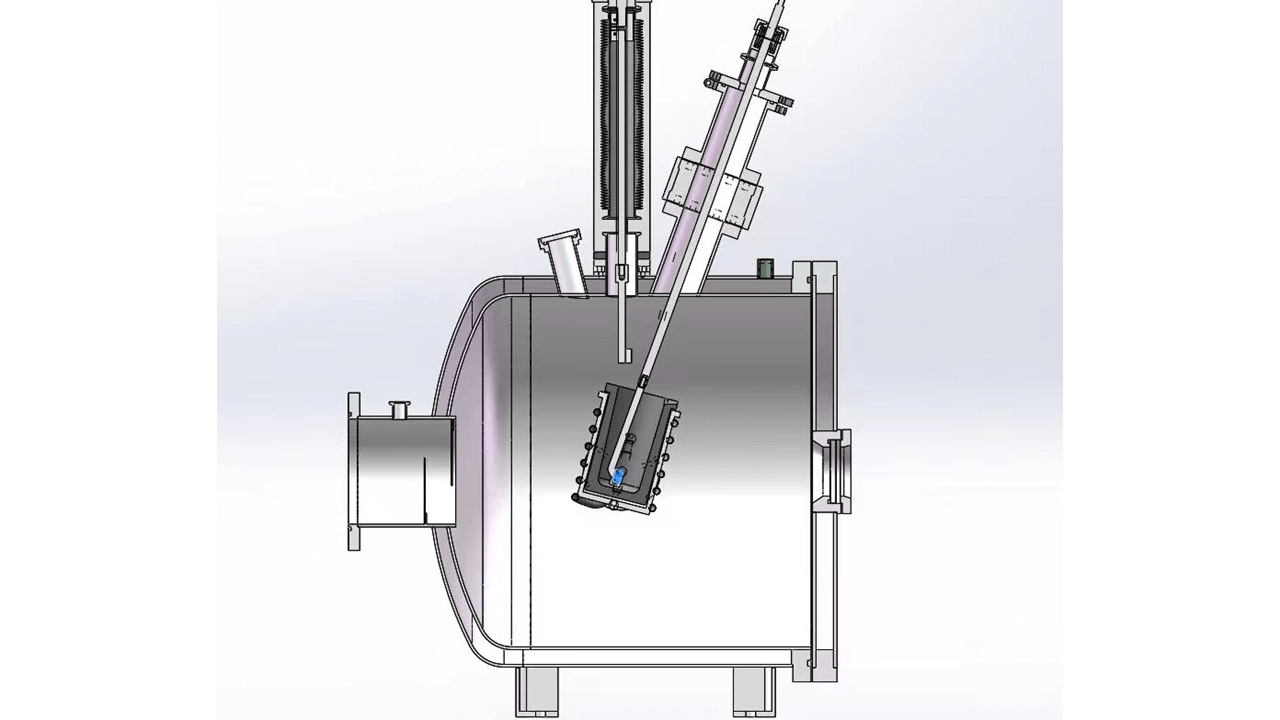

The vacuum reclaiming device is composed of stainless steel pushrod, transition bin, high vacuum gate valve, quartz reclaiming spoon, etc; A reclaiming spoon is installed at the lower end of the push-pull rod. The push-pull rod is sealed with a JO seal ring between the push-pull rod and the transition chamber. The transition chamber and the vacuum chamber are connected through a high vacuum gate valve. When the chamber is vacuumized, open the flapper valve, and the reclaiming chamber will be vacuumized accordingly. After the materials are melted, the push-pull rod will push down for reclaiming, then pull to the transition chamber, close the gate, and open the transition chamber door to take the materials just taken out for testing. If it is necessary to take materials again, install the push rod again, close the transition bin door, and then vacuum the transition bin. After vacuum pumping, open the flapper valve to realize continuous vacuum reclaiming.

| Model | CDO-VIF-0.5 | CDO-VIF-1 | CDO-VIF-1-G | CDO-VIF-2 | CDO-VIF-3 | CDO-VIF-5 | CDO-VIF-10 | CDO-VIF-25 |

| Max Capacity | 0.5kg(iron) | 1kg(iron) | 1kg(iron) | 2kg(iron) | 3kg(iron) | 5kg(iron) | 10kg(iron) | 25kg(iron) |

| Max Temperature | 1800℃ | 1800℃ | 2100℃ | 1800℃ | 1800℃ | 1700℃ | 1700℃ | 1700℃ |

| Power Supply | HF induction power supply |

HF induction power supply |

HF induction power supply |

HF induction power supply |

MF induction power supply |

MF induction power supply |

MF induction power supply |

MF induction power supply |

| Oscillation frequency | 30-80KHZ | 30-80KHZ | 30-80KHZ | 30-80KHZ | 1-20KHZ | 2KHZ | 1-20KHZ | 1-20KHZ |

| Chamber Inner Dia | 300mm | 400/500mm | 400/500mm | 500mm | 500mm | 600mm | 750mm | 800mm |

| Power Supply | AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

AC/3P/380V/ 50/60Hz |

| Max Input Power | 15KW | 15/25KW | 35KW | 25KW | 35KW | 80KW | 80KW | 120-160KW |

| Heating Current | 2-50A | 2-50A | 12-70A | 2-50A | 10-70A | 134A | 167A | 201A |

| Cold Ultimate Vacuum | < 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

< 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

< 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

< 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

< 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

< 5X10 -4Pa (molecular pump); 5×10-3 Pa (Diffusion pump) |

5×10-3 Pa (Diffusion pump) |

8×10-3Pa (molecular pump) |

| Chamber Filling Pressure | < 0.05MPa | < 0.05MPa | < 0.05MPa | < 0.05MPa | < 0.05MPa | < 0.05MPa | < 0.05MPa | < 0.05MPa |

| Pressure Rise Rate | <4Pa/h | <4Pa/h | <4Pa/h | <4Pa/h | <4Pa/h | <4Pa/h | <4Pa/h | <4Pa/h |

| Vacuum Pump | Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

Molecular pump/ diffusion pump |

| Control Accuracy | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C | ±1 to 5°C |

1. Laboratory Vacuum Induction Melting Furnace has fashionable appearance and compact structure, covering an area of less than 2 square meters.

2. The vacuum furnace can be designed as a side door opening structure, which is convenient for taking and placing materials.

3. The furnace shell adopts a double-layer water cooling structure, and the surface temperature does not exceed 40 ℃, which is safer and reliable.

4. An observation window is arranged on the furnace cover to facilitate the observation of material melting. Gas inlet and outlet are installed on the furnace body, and multiple KF interfaces are reserved to facilitate connection to other devices.

5. The electrode can rotate.

6. Equipped with a secondary feeding device, other elements can be added in the smelting process to make various alloy materials.

7. IGBT special power supply and all digital circuits are adopted. The electrical system is equipped with overcurrent, overvoltage feedback, and protection circuit. The electric control panel box is made according to Siemens standard, with high temperature control accuracy and convenient operation.

8. Our small laboratory vacuum induction melting furnace can adopt two-stage pump, that is, mechanical pump and molecular pump, and the vacuum degree can reach 8 × 10-4P.

– Proven Reliability: Backed by years of engineering expertise, our systems are trusted by leading research institutions worldwide.

– Customization Options: We understand that no two research projects are alike. Our team works closely with you to tailor the furnace to your specific needs, from vacuum pump configurations to crucible materials.

– Comprehensive Support: From installation and training to maintenance and troubleshooting, we provide end-to-end support to ensure seamless integration into your workflow.

– Temperature Range: Up to 2000°C (optional upgrades available for higher temperatures).

– Vacuum Level: Configurable from medium vacuum (10⁻³ mbar) to ultra-high vacuum (10⁻⁸ mbar).

– Heating Elements: Graphite or molybdenum disilicide (MoSi₂) options, depending on application.

– Cooling System: Advanced water-cooling circuitry for rapid quenching and efficient thermal management.

– Control System: PLC-based interface with data logging and remote monitoring capabilities.

In the competitive landscape of materials research, having the right tools can make all the difference. Our laboratory vacuum furnace offers the precision, flexibility, and reliability needed to push the boundaries of innovation. Whether you’re exploring new alloys, developing advanced ceramics, or conducting fundamental studies, this furnace is designed to empower your research.

*Contact us today to learn more about how our vacuum furnace can elevate your laboratory’s capabilities. Request a personalized quote or schedule a demo to see the system in action!

All material crucibles can be used in this small furnace, which can suit for different metal

Sampling System and Secondary Alloy Adding Can be added, during melting process, you can take sample or add materail into the crucible

Inner Tilting Design,After melting, the crucible can be tilt manually or by hydraulic tilting into the casting mold,

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About Laboratory Vacuum Induction Melting Furnace

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….