Gold Silver Coin Minting Machine

Gold and silver have long been regarded as safe-haven assets, especially during times of economic uncertainty, political instability, or financial crisis. While traditional investments like stocks, real estate, and mutual funds can be highly volatile, gold and silver tend to retain—or even increase—in value. This makes them an excellent hedge against inflation and currency devaluation.Precious metals are commonly transformed into jewelry, bars, and coins. Among these, gold and silver coins are particularly popular due to their portability, recognition, and aesthetic appeal.

Key Advantages of Gold and Silver Coins:

- Safety: Globally recognized as a secure store of value.

- Liquidity: Traded 24/7 in global markets, easily converted to cash.

- Stability: Often appreciate when fiat currencies lose value.

- Scarcity: Limited supply with growing demand.

- Investment Potential: Low-risk, long-term growth potential with minimal market manipulation.

Title

How to Mint a Fine Gold/Silver Coin:

*Chapter I – Introduction to coins

1.1. Development

1.2 Coins Type

*Chapter II – How To Make Shinning Gold/Silver Bullion?

2.1 Step 1: Gold/Silver Vacuum Bullion Casting Machine

2.2 Step 2: Hydraulic logo stamping for bullion

*Chapter III – The Production Process of Coin

3.1 Step 1: Silver/Gold strip casting

3.2 Step 2 .Rolling mill treatment of gold bar surfaces

3.3 Step 3: Obtaining Coin Blank

3.4 Embossing

*Chapter IV – Guide purchase of minting machine

*Chapter V – Conclusion

*Chapter I – Introduction to coins

Gold and silver coins are not only financial assets but also powerful tools for wealth preservation. Their ability to withstand economic downturns and inflation is unmatched by paper currencies.

1.1 Historical Development

The value of commemorative gold and silver coins is influenced by several factors: material value, thematic significance, minting technology, and limited mintage. While the face value may be lower than the metal value, their collectible and artistic worth often leads to significant appreciation.

Popular gold coins traded worldwide include:

South African Krugerrand

British Britannia

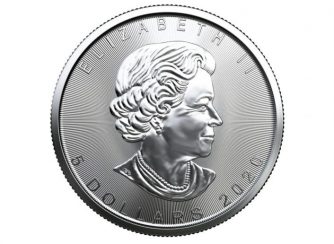

Canadian Maple Leaf

American Eagle & Buffalo

Mexican Gold Peso

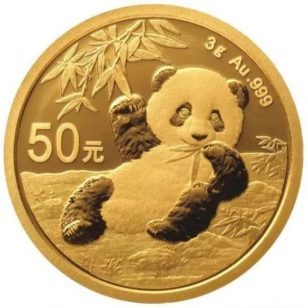

Chinese Panda Coin

Commemorative coins, especially limited editions, often carry higher premiums due to their rarity and craftsmanship.

1.2 Prominent Coin Types

Krugerrand Gold Coin: The original modern bullion coin, made from a durable 22K gold alloy (916.7 fineness).

Maple Leaf Gold Coin :Renowned for its 9999 pure gold content and intricate radial lines.

American Buffalo Gold Coin: The first 9999 fine gold coin issued by the United States Mint.

American Eagle Gold Coin: A iconic 22K gold coin, containing alloy for added durability.

Chinese Panda Gold Coin: Famous for its annual changing design and high 999 fine gold quality.

*Chapter II: The Production Process of Gold/Silver Bullion

Introduction:

Traditional bullion casting methods often result in products with surface imperfections like bubbles, ripples, and oxidation, which deter discerning investors. Modernvacuum casting technology is the solution, producing mirror-finish, high-density bullion** that commands a premium in the market.

2.1 Step 1:Precision Bullion Casting with Vacuum Technology

Vacuum gold/silver bullion casting machine

The CDOCAST Vacuum Gold/Silver Bullion Casting Machine is engineered to produce flawless, investment-ready bullion. This vacuum induction melting furnace operates in a completely sealed environment, either under a high vacuum or an inert gas atmosphere (Argon/Nitrogen), to eliminate oxidation entirely.

Workflow:

1. Pre-weighed metal is placed into a custom graphite mold.

2. The chamber is sealed, and an automated cycle begins.

3. The system automatically creates a vacuum, melts the metal, and back-fills with inert gas.

4. Controlled cooling ensures a perfect, ripple-free surface with a mirror finish.

Technical Features & Advantages:

PLC & Siemens Touchscreen Control: For full automation, repeatability, and ease of use.

Zero Oxidation & Metal Loss: The closed vacuum/inert gas system guarantees maximum metal yield and purity.

Mirror-Finish Surface: Eliminates the need for extensive post-casting polishing.

Integrated Safety Alarms: Monitors for over-voltage, over-current, and water cooling issues.

Industrial-Grade Durability: Designed for 24/7 continuous operation in high-volume refineries.

↓↓↓

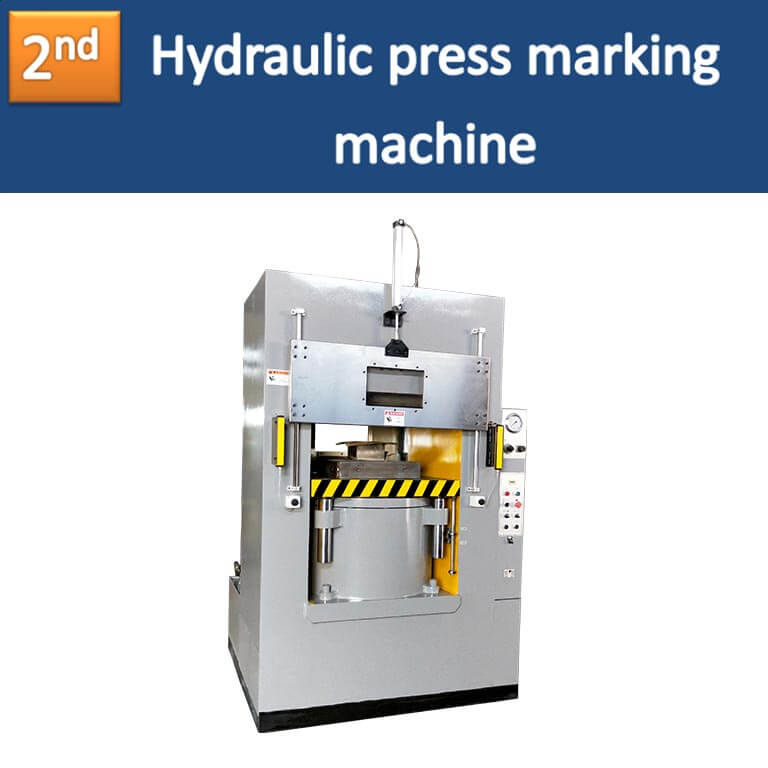

2.2 Step 2:High-Pressure Hydraulic Logo Stamping

After casting, a precise impression is made using the CDOCAST Hydraulic Press Machine. This machine delivers the immense, controlled force required to stamp sharp, deep logos and designs onto the bullion.

Stamping Process:

1. The smooth bullion is placed in the press.

2. A custom-fabricated, hardened stamping die is positioned on top.

3. The hydraulic system applies dozens to hundreds of tons of pressure, transferring the design perfectly.

4. The result is a professional, branded bullion bar.

Customization is Key: We can create custom dies based on your 3D engineering drawings for any logo, pattern, or shape, ensuring your product stands out.

↓↓↓

*Chapter III: Gold and Silver Coin Minting Process

This process is more complex than bullion production, involving multiple stages to create a finished, legal-tender-style coin.

3.1 Step 1: Continuous Casting of Gold/Silver Strips

Continuous casting machine for gold/silver strip casting

The Continuous Casting Machine for Gold/Silver Strips produces a consistent, uniform strip of metal, which is the raw material for coin blanks. It uses intermediate frequency induction heating in a graphite crucible and mold system under inert gas protection.

Key Features:

Customizable Graphite Molds: Produce strips of exact width and thickness required for your coin blanks.

High Efficiency & Automation: Enables continuous production of strip metal for high-volume minting.

Integrated Hydraulic Shear: Casts the continuous strip into manageable lengths.

↓↓↓

The features and advantages of the continuous casting machine:

1. The heating system with graphite crucible and induction technology can ensure 24-hour continuous operation to meet the production requirements of different customers

2. Graphite mold design can be customized according to the shape type to meet the casting requirements of various shapes

3. High production efficiency, can produce different shapes and sizes of alloy or semi-finished products in the shortest time.

4. Siemens control system can guarantee the quality of our jewelry casting machine

5. The whole process will be carried out under the complete inert gas protection of the crucible and mold system, of course, the vacuum design can also be used

6. With hydraulic shear, it is very convenient to cut large plate

3.2 Step 2:Precision Rolling to Gauge

The cast strips are then passed through a Precision Rolling Mill. This machine uses incredibly hard rollers to compress the metal to the exact thickness (gauge) required for the final coin. The process also work-hardens the metal and improves its surface finish. Intermediate annealing in a furnace may be used to restore ductility between rolling passes.

↓↓↓

3.3 Step 3: Obtaining the Coin Blank

The Hydraulic Punching Machine cuts precise coin blanks from the rolled strips. It supports various shapes and ensures minimal burring.

Features:

Four-column structure for stability

Programmable hydraulic system

Annealing and polishing options for superior finish

↓↓↓

Last but not least, in order to ensure the minimum burr and edge of the blank and avoid any pollution and scratch, annealing and polishing are carried out immediately. But be careful not to polish too much, which may make the coin lose its mirror effect.

3.4 Step 4: Embossing – The Art of Coin Stamping

The final and most critical step is embossing, where the blank is struck with dies under immense pressure to create the coin’s obverse and reverse designs. The CDOCAST Hydraulic Coining Press is built for this task, delivering the necessary force to create sharp, high-relief images.

Safety & Control:

Photoelectric Safety Guards: Protect the operator’s hands.

Emergency Stop System: For immediate shutdown.

Programmable Logic Controller (PLC): Manages the strike cycle for consistency.

Chapter IV: A Guide to Purchasing Your Minting Machine

Selecting the right equipment is crucial. Consider:

Production Goal: Are you focusing on bullion bars or detailed coins?

Material & Purity: What metals and purities will you be using?

Output Volume: Do you need benchtop units or industrial 24/7 production lines?

Level of Automation: Fully automatic, semi-automatic, or manual control?

Customization Needs: Will you require custom graphite molds or stamping dies?

CDOCAST provides end-to-end solutions, from single machines to complete, integrated minting lines, tailored to your specific requirements.

Chapter V: Conclusion

Investing in a modern gold and silver coin minting machine not only enhances production efficiency but also ensures high-quality, market-ready products. With advanced technologies like vacuum casting, hydraulic pressing, and automated rolling, minting has never been more accessible or reliable.

Whether you’re a private mint, refinery, or collector, understanding the full minting process helps in making informed decisions and maximizing investment returns.

CDOCAST hydraulic logo marking machine is equipped with the following electrical protection device, so the operation will be safe:

1. Short circuit protection of main circuit and control circuit is realized by fuse.

2. Overload protection of motor is realized by thermal relay.

3. This machine is equipped with “emergency stop” button SB1 to realize emergency stop.

4. The machine has been installed with photoelectric protection device to ensure the safety of the operator.

5. The machine is equipped with a special grounding device for the electrical box.

*Chapter IV – Guide purchase of minting machine

If you want to mint high-quality coins, purchasing good Gold Silver Coin Minting Machine is very significant. The following machines are essential for you to make good coins:

1. Jewelry Continuous Casting Machine/ Vacuum Bullion Casting Machine

2. Rolling Mill

3. Annealing Furnace

4. Hydraulic Punch Machine

5. Hydraulic Press Machine

When selecting the equipment or machine for gold silver coin minting, it is necessary to identify whether the equipment has the following functions:

1. Does the machine provide gas (vacuum) protection?

A good gold coin has a glossy surface. In the manufacturing process, it needs to provide a vacuum environment to prevent oxidation and shrinkage. Otherwise there will be rust layer on the surface, affecting sales and causing great loss. Therefore, gas protection is very essential. The jewelry continuous casting machine / vacuum bull casting machine sold by CDOCAST are all vacuum protected, and the gold bars produced have mirror effect.

2. Is the coin minting line automatic?

With the development of technology, high efficiency and intelligent operation are pursued by every manufacturers. Additionally, it can help reduce the labor. 1-2 workers is enough for the whole coin minting line. Press the button to start the machine and it will be produce the goods as you want. If you want full automatic line, CDOCAST can also offer you with the manipulator. More details, please contact us.

3. Is your gold coin making machine compatible with other equipment?

Most of the coin making machines are used alone. They need to be collaborated with other devices to complete the work. Therefore, it is important that the equipment you purchase can work smoothly with other types of equipment.

4. Is coin minting line environmentally friendly?

The issue of environment protection is always a focus in our current world, and will be a long-term problem existing in future. In some countries, the requirements for environmental protection are strictly and clearly stipulated. So you have to focus on whether the machine will produce waste gas and waste water, which will pollute the air, soil, water and so on.

5. Will the equipment supplier provide instructions or video guide?

You may be in contact with the production line for the first time, and you are not familiar with the operation and production process of the new line. A manual or the guidance of an experienced person will help you quickly get familiar with the whole process and operation soon , improving efficiency and avoiding mistakes. Additionally, the instructions needs to mention the maintenance methods and troubleshooting to help you maintain your own machine better.

6. Whether the manufacturer can provide satisfactory after-sales service?

Normally, the manufacturer will provide a one-year warranty period. In case of non-human damage, if there is mechanical failure, you can return the machine for repair or replace the parts for free. For brand new machines, there may be few problems. But some gold coin manufacturers will buy second-hand machines considering the cost, there’s gonna be a lot of glitches. So don’t consider the manufacturer that the warranty is less than one year or even not provided, CDOCAST will offer 2-year warranty.

Additionally, mold design is a unique and important link in the coinage process. After strict examination and approval of the subject matter, patterns, through the sophisticated and exquisite carving of the mint, combined with the use of modern precision equipment, the design intent is expressed in the mold. In order to highlight the visual effect, the main relief of the depression has a fine frost surface, and the higher places need to be ground into a mirror surface.

In order to maintain the original color of the coins within a certain period of time, the surface of each coin must be protected. At the same time, it should be placed in a plastic box, sealed with a plastic film, and then put into a specially designed packaging box, and all the finished products should be subject to strict inspection.