- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the most advanced annealing furnace in the market, inquiry now!

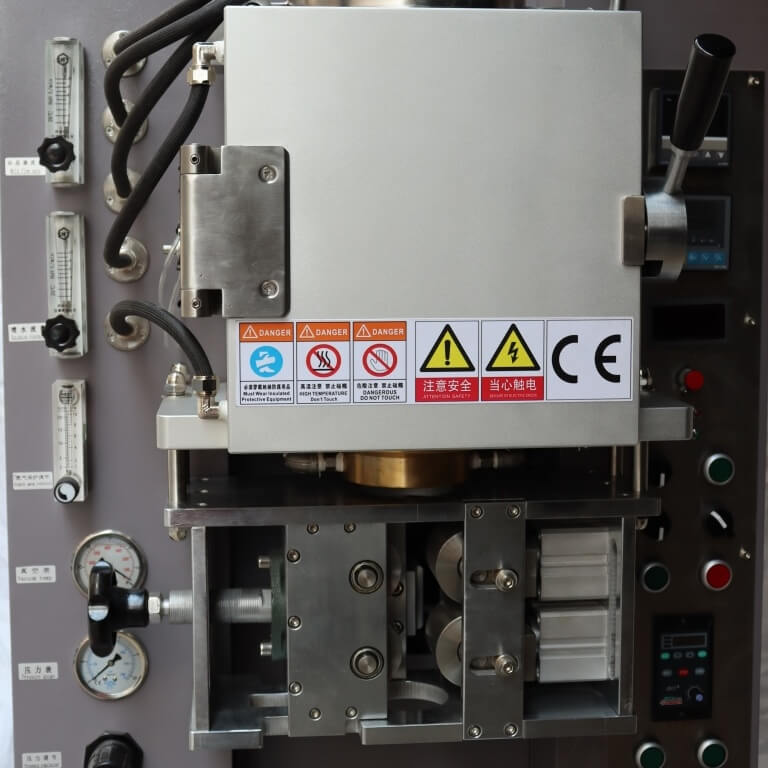

Annealing precious metals requires a perfect balance of temperature control, atmospheric purity, and operational efficiency. CDOCAST annealing furnaces are engineered to deliver precisely that. Designed specifically for the annealing of gold, silver, platinum, and other precious metals, our furnaces integrate innovative technology to ensure superior results in every cycle.

At the core of the CDOCAST annealing furnace is a high-temperature resistance wire heating system. This technology enables exceptional temperature distribution across the heating chamber, eliminating hot spots and ensuring consistent annealing. With fully programmable controls, users can tailor the heating process to specific material requirements, achieving optimal ductility and material integrity.

The integrated cooling water tank allows workpieces to be rapidly cooled after heating, significantly reducing processing time while preserving metallurgical characteristics. Moreover, the furnace supports inert gas environments, such as nitrogen, to prevent oxidation during annealing. This ensures that precious metals retain their luster and purity, free from tarnish or surface degradation.

For customers seeking additional flexibility and cost savings, CDOCAST offers an optional ammonia heating and decomposition device. When heated, ammonia breaks down into nitrogen and hydrogen, creating a reducing atmosphere that enhances workpiece brightness. This solution not only improves visual quality but also lowers operational costs, making it an ideal choice for high-volume applications.

Constructed from high-grade stainless steel, the heating chamber combines durability with exceptional heat resistance. A specially designed combustion device at the furnace entrance actively prevents oxygen ingress, maintaining an oxygen-free environment throughout the annealing process. This critical feature safeguards against oxidation, ensuring flawless results batch after batch.

The CDOCAST furnace simplifies operation with its user-friendly design. Once annealing is complete, the loaded metal rack can be effortlessly pushed and rotated, allowing workpieces to descend directly into the cooling pool for immediate quenching. The annealed components are then easily retrieved, ready for the next production stage. This seamless workflow minimizes handling time and maximizes throughput.

Whether you are crafting jewelry, producing industrial components, or refining high-purity materials, CDOCAST annealing furnaces offer the reliability and precision demanded by today’s competitive markets. By combining advanced heating, atmospheric control, and operational simplicity, our furnaces help manufacturers achieve higher quality outcomes while reducing energy consumption and costs.

Explore how CDOCAST can transform your annealing process. Contact us today to learn more about our customizable solutions and industry-leading support.

1 Meter Channel Annealing Furnace:

1 Meter Channel Annealing Furnace:

| Model number | CDO-AF16 |

| Voltage | Three phase 380V±10%, 50/60Hz |

| Power | 16kw |

| Weight | 350kg |

| External dimensions | 850*1800*1200mm(L*W*H) |

| Maximum temperature | 1000℃ |

| Protective gas | Ammonia, nitrogen, or nitrogen-hydrogen mixture |

| Furnace chamber material | High temperature resistant burnt gems |

| Stainless steel material of chamber and furnace door | 310s Stainless steel |

| Heating zone | 450*200*100mm(L*W*H) |

1:Uniform heating with minimum difference of temperature.

2:The entire annealing is completed in inert gas protection, the workpiece does not have oxide scale, which can greatest guarantees the quality of workpiece

3:Small foot print design , no need to send engineers to debug, end-user can install by themselves

4:Heating Temperature curve program can be set

5:Installed with a timer, you can set the start-up time at any time.

6:Optionally, an ammonia heating and decomposing unit is available, allowing direct annealing with ammonia

Q1. What types of metals can be annealed?

A: It can anneal various precious metals such as gold, silver, and platinum, as well as metals like copper, brass, and stainless steel.

Workpiece forms: Capable of bright annealing for rods, tubes, wires, plates, sheets, and small workpieces.

Q2. What protective gases can be used?

A: Ammonia, nitrogen, or a nitrogen-hydrogen mixture.

Q3. Does the annealing furnace include an ammonia dissociator?

A: We offer two models: one with an ammonia dissociator and one without. Clients must specify their requirements before purchase.

The ammonia dissociator decomposes ammonia into hydrogen and nitrogen. Nitrogen prevents metal oxidation, while hydrogen acts as a reducing agent, resulting in a brighter metal surface.

Q4. What is the maximum achievable temperature?

A:The maximum temperature reaches 1000°C, which is sufficient for most applications.

Q5. What is the temperature fluctuation range?

A: Once the set temperature is reached, the fluctuation is within ±2°C, ensuring consistent heat treatment results.

Q6. What are the heating zone dimensions? Can a larger heating zone be customized?

A: The standard heating zone is 450*200*100mm (L*W*H). The heating zone can be customized based on production volume and workpiece size. However, an excessively large heating zone is not recommended, as increased size can amplify the temperature difference between the furnace wall and the central area, leading to reduced temperature uniformity and compromised heat treatment consistency.

Q7. What is the heating principle of the machine?

A: It employs high-temperature resistance wire heating elements arranged around the furnace chamber, ensuring even temperature distribution inside.

Q8. How are heated metals cooled?

A: After annealing, simply push and rotate the loaded metal rack to directly tip the high-temperature workpieces into the water tank on the side of the furnace for immediate quenching. Quenched metal materials can then be removed directly.

Q9. Besides protective gas, are there other anti-oxidation measures?

A: Yes. This equipment features a dual anti-oxidation design:

A gas combustion device at the inlet creates a high-temperature flame curtain, effectively isolating external oxygen.

Positive pressure atmosphere inside the furnace: Continuously supplied protective gas maintains a slight positive pressure within the chamber, further preventing air infiltration.

Q10. What preparations are required for machine installation?

A: Protective gas and gas supply must be prepared in advance. The protective gas flow rate requirement is 6-8L per minute. There is no special requirement for gas flow rate; normal combustion is sufficient.

Q11. How are heating time and temperature determined?

A: Heating time depends on the size, thickness, and quantity of the material being annealed. Temperature is determined by the material, for example: gold around 750°C, platinum around 800-850°C. First-time users can consult our engineers and adjust parameters based on annealing results in subsequent uses.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Argon Annealing Furnace

Contact Our Engineer Team

CDOCAST Jewelry Continuous Casting Machine For making jewelry into wire, rod , plate

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….