- Call Us: 008615168765707

- Mail Us: [email protected]

Buy jewelry vacuum casting machine with the most advanced technology

With the continuous development of modern industry, material science, and manufacturing technology are also constantly innovating. In the field of casting, vacuum pressure casting furnace has attracted widespread attention as a key technology. It achieves significant improvements in material properties and casting quality by applying vacuum and pressure during the casting process. This article will delve into the principles, advantages, and application fields of vacuum pressure casting furnaces, aiming to demonstrate the importance and potential of this technology.

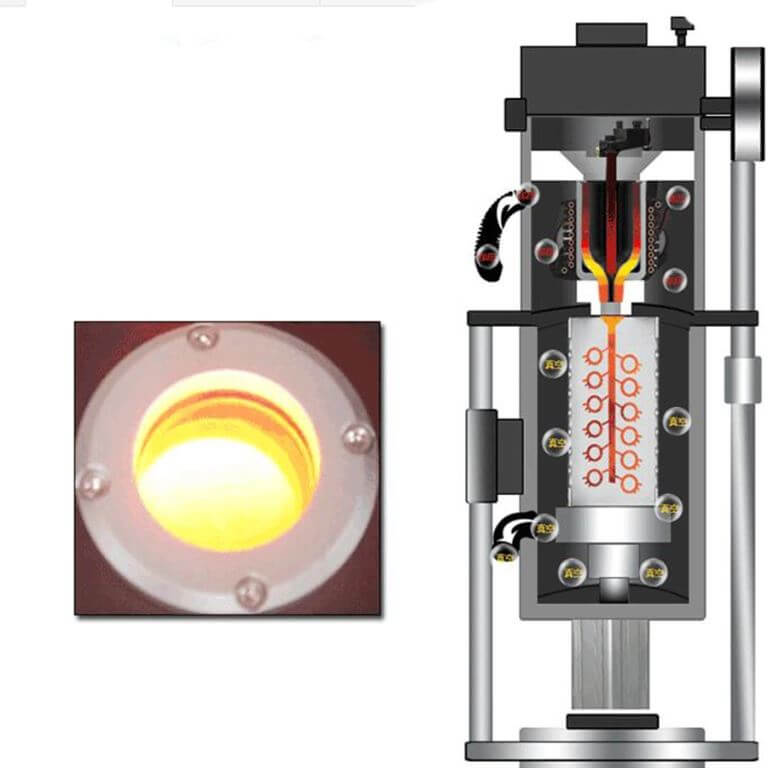

Vacuum pressure casting furnace is an advanced casting technology, whose core lies in controlling the atmosphere during the casting process to achieve a high vacuum environment and apply additional pressure. This process involves the following key steps

1.1 Vacuum treatment: Before the start of the casting process, the air inside the vacuum casting machine will be extracted to create a high vacuum environment. This can eliminate the presence of gases and impurities, thereby reducing the internal porosity of the casting and improving its density and uniformity

1.2 Pressurization operation: In a vacuum environment, pressure casting can be achieved by applying additional pressure to the molten metal. This pressure can eliminate bubbles inside the casting and promote a more uniform filling of the molten metal into the mold, thereby reducing shrinkage cavities and defects

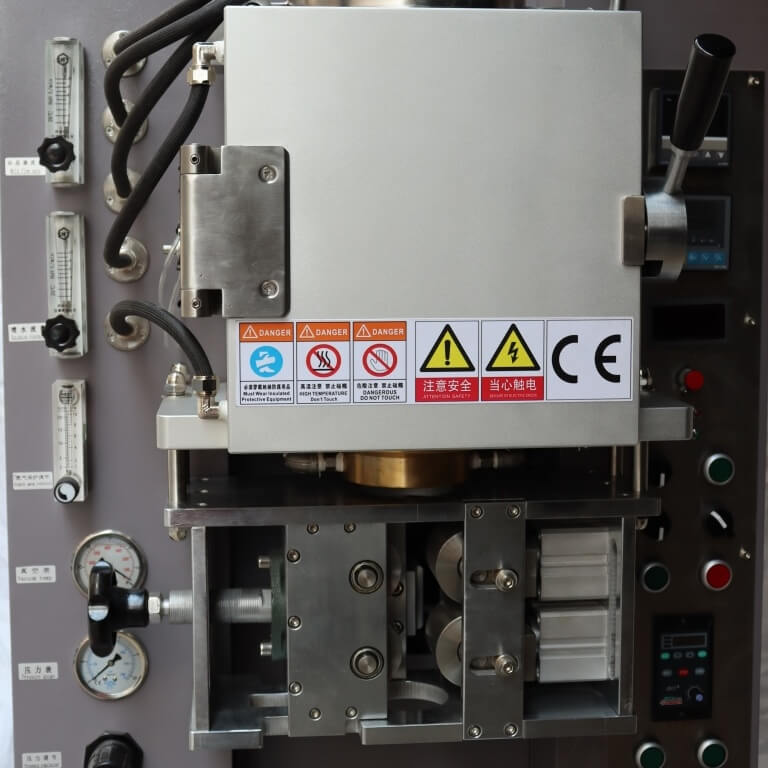

CDOCAST Jewelry Vacuum Casting Machine is customized and made to melt and cast 1-6 kg of jewelry gold, silver, and other precious metals. Precious metal is melted and cast in an argon-protected atmosphere under a vacuum to protect your precious jewelry from oxidation, It achieves high density, high compactness, almost no air bubbles, and basically achieves non-shrinkage cavity casting. Any precise jewelry and metal artwork can be perfectly done with the CDOCAST Jewelry Casting Machine. We also offer a year-round warranty and worldwide on-site training services.

CDOCAST can provide a turn-key set of jewelry casting solutions, including a wax injection machine, wax lost heating oven, jewelry vacuum casting machine &washing machine ..etc. If you want to cast your own designed jewelry, please send us an inquiry, our experts will give you Professional design solutions within 24 hrs.

Ready to receive a personalized quote for your Jewelry Vacuum Casting Machine? CLICK TO REQUEST A QUOTE TODAY.

| Model number | CDO-JP1 | CDO-JP2 | CDO-JP4 | CDO-VP2 | CDO-VP4 |

| Power | 6kw | 15kw | 20kw | 15kw | 20kw |

| Voltage | 220V,single phase ,50/60Hz | 380V,3 phase, 50/60Hz | |||

| Casting system | Vacuum pressure casting system | ||||

| Applicable metal | Gold, K-Gold, Silver, Copper, etc. | ||||

| Melting time | 3-5min | 3-5min | 3-5min | 3-5min | 3-5min |

| Capacity | 24K Gold: 1 KG 18K Gold: 0.75 KG 925 Silver: 0.5 KG |

24K Gold: 2 KG 18K Gold: 1.5 KG 925 Silver: 1 KG |

24K Gold: 4 KG 18K Gold: 3 KG 925 Silver: 2 KG |

24K Gold: 2 KG 18K Gold: 1.5 KG 925 Silver: 1 KG |

24K Gold: 4 KG 18K Gold: 3 KG 925 Silver: 2 KG |

| Max temperature | 1600℃ | 1600℃ | 1600℃ | 1600℃ | 1600℃ |

| Protective gas | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon | Nitrogen or Argon |

| Operation system | Manual | Manual/Auto | Manual/Auto | Manual/Auto | Manual/Auto |

| Max pressure | 0.2 MPa | 0.2 MPa | 0.2 MPa | 0.4 MPa | 0.4 MPa |

| Overall size | 645*625*935mm | 800*800*1350mm | 800*800*1350mm | 820*830*1400mm | 820*830*1400mm |

| Weight | 130kg | 270kg | 290kg | 350kg | 370kg |

| Model number | CDO-GM5 | CDO-GM8 |

| Power | 750W | 1500W |

| Voltage | 380V,3P,50/60Hz | 380V,3P,50/60Hz |

| Max flask size | 4*10 inch | 4*10 inch |

| Capacity | 5 pcs | 8 pcs |

| Weight | 120KG | 180KG |

| Dimension | 700*680*1400mm | 1000*1000*1550mm |

| Other sizes can be customized | ||

The parameter of vacuum gypsum mixer pump

| Model number | CDO-GMP15 | CDO-GMP30 | CDO-GMP70 |

| Voltage | 380V,3P,50/60Hz | 380V,3P,50/60Hz | 380V,3P,50/60Hz |

| Power | 2.2KW | 3KW | 5.5KW |

| Rotary speed | 320RPM | 450RPM | 420RPM |

| Oil Capacity | 2.8L | 2L | 4.2L |

| Weight | 190KG | 236KG | 338KG |

| Dimension | 790*530*540mm | 780*500*560mm | 910*650*700mm |

1: CDOCAST Jewelry Vacuum Pressurized Casting Machine is designed with the most advanced PID temperature control, maximum temperature can reach up to 1600 degrees Celsius, with a temperature difference of only 2 degrees.

2: The strong induction electromagnetic stirring force makes the metal solution more uniform, and the casting quality is higher.

3: The entire melting and casting process is carried out under vacuum, thus minimizing metal oxidation and minimizing metal loss.

4: CDOACAST Jewelry Vacuum Pressurized Casting Machine Equipped with various safety alarms, such as over-current, over-pressure, water shortage and other alarms, when an emergency occurs, the machine can automatically stop

5: Integrated design of the melting and casting chambers for a more compact structure and a smaller footprint for our Jewelry Casting Machine

6: Jewelry Vacuum Casting Machine’s Pressurized casting design highly improves castings’ density and no porosity compared with the traditional casting

1:Improving the quality of castings: The vacuum pressure casting machine reduces the presence of gases and impurities, making the internal structure of castings dense and reducing the generation of defects such as pores and shrinkage. This helps to improve the mechanical properties and corrosion resistance of castings, making the final product more reliable.

2:Enhanced alloy properties: In a vacuum environment, the oxidation reaction during the casting process is suppressed, thereby reducing the oxidation loss of the alloy. This can maintain the content of specific elements in the alloy and improve its properties and properties

3:Support for complex structural castings: Vacuum pressure casting furnaces can effectively cast castings with complex structures and rich details, as high vacuum environments and pressure operations can ensure more uniform flow of molten metal in the mold, filling fine voids

4: Energy saving: Compared with traditional casting methods, vacuum pressure casting furnaces have lower energy consumption. Due to faster heating and cooling rates in high vacuum environments, the entire casting cycle is shorter, saving energy and time costs.

A: Our vacuum pressure casting machine significantly improves casting quality by effectively eliminating common defects like shrinkage pores, gas holes, and slag inclusions. This results in denser, higher-quality castings. The fully automated process also boosts production efficiency and reduces the need for manual labor, making it ideal for high-volume manufacturing.

A: The machine is equipped with a user-friendly Siemens touchscreen and a PLC control system. Operators can easily set parameters such as temperature, pressure, and cycle time on the screen. Once configured, the machine runs automatically, ensuring consistent and precise results with minimal operator intervention

A: Yes, the machine is suitable for casting gold and silver. However, due to its high melting point and poor fluidity in molten form, platinum requires a centrifugal casting machine for optimal results.

A: The Aluminum-shell model offers better sealing and higher pressure resistance because its cylinder is made from a single piece of aluminum, ensuring no air leakage.

The Steel-shell model, with its welded cylinder, may be prone to leaks over time. While the aluminum-shell version is more expensive, it provides superior performance and durability.

A: The steel-shell machine supports flasks up to φ5×10 inches, while the aluminum-shell model can accommodate larger flasks up to φ5×14 inches.

A: The steel-shell model operates at 2 MPa, while the aluminum-shell model can reach up to 4 MPa, allowing for denser and more detailed castings.

A: Electromagnetic stirring is a non-contact technology that uses electromagnetic forces to mix molten metal evenly. This is especially useful for alloys like K-gold, as it ensures uniform composition and reduces defects, resulting in higher-quality castings.

A: With the electromagnetic stirring function, the machine ensures homogeneous mixing of molten metal, enabling the production of extremely fine details—comparable to the fineness of a human hair, even with K-gold materials.

A: Metal loss is primarily due to oxidation and varies with the material and casting temperature. For example, in a test using 18K gold at 1060°C, the loss rate was approximately 0.125%. Higher temperatures generally lead to increased loss.

A: Installation requires access to water, electrical power (total machine power ~20 kW, with a minimum 60A circuit breaker), protective gas, and an air compressor (30L capacity is sufficient).

We offer free online guidance for installation. If on-site assistance is required, clients are responsible for covering the visa, flight tickets, accommodation, and the engineer’s service fees

A: Regular maintenance is crucial for ensuring machine longevity and stability. Weekly/monthly tasks include inspecting seal rings for wear, cleaning vacuum line filters, and checking electrical connections. Vacuum oil should be replaced approximately every month to prevent clogging due to contamination.

– Crucible: ~50 uses – Graphite rod: ~30 uses – Thermocouple:Several months

A: Our vacuum pressure casting machine significantly improves casting quality by effectively eliminating common defects like shrinkage pores, gas holes, and slag inclusions. This results in denser, higher-quality castings. The fully automated process also boosts production efficiency and reduces the need for manual labor, making it ideal for high-volume manufacturing

A: The machine is equipped with a user-friendly Siemens touchscreen and a PLC control system. Operators can easily set parameters such as temperature, pressure, and cycle time on the screen. Once configured, the machine runs automatically, ensuring consistent and precise results with minimal operator intervention.

A: Yes, the machine is suitable for casting gold and silver. However, due to its high melting point and poor fluidity in molten form, platinum requires a centrifugal casting machine for optimal results

A: The Aluminum-shell model offers better sealing and higher pressure resistance because its cylinder is made from a single piece of aluminum, ensuring no air leakage.

The Steel-shell model, with its welded cylinder, may be prone to leaks over time. While the aluminum-shell version is more expensive, it provides superior performance and durability.

A: The steel-shell machine supports flasks up to φ5×10 inches, while the aluminum-shell model can accommodate larger flasks up to φ5×14 inches.

A: The steel-shell model operates at 2 MPa, while the aluminum-shell model can reach up to 4 MPa, allowing for denser and more detailed castings.

A: Electromagnetic stirring is a non-contact technology that uses electromagnetic forces to mix molten metal evenly. This is especially useful for alloys like K-gold, as it ensures uniform composition and reduces defects, resulting in higher-quality castings.

A: With the electromagnetic stirring function, the machine ensures homogeneous mixing of molten metal, enabling the production of extremely fine details—comparable to the fineness of a human hair, even with K-gold materials.

A: Metal loss is primarily due to oxidation and varies with the material and casting temperature. For example, in a test using 18K gold at 1060°C, the loss rate was approximately 0.125%. Higher temperatures generally lead to increased loss.

A: Installation requires access to water, electrical power (total machine power ~20 kW, with a minimum 60A circuit breaker), protective gas, and an air compressor (30L capacity is sufficient).

We offer free online guidance for installation. If on-site assistance is required, clients are responsible for covering the visa, flight tickets, accommodation, and the engineer’s service fees.

CDOCAST also offer solutions for high quality wax injection machine and dewaxing burnout oven

Pressurized casting improves density and non-porosity of castings

CDOCAST jewelry casting machine improve casting success and jewelry quality compared to conventional casting.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Jewelry vacuum casting machine

Contact Our Engineer Team

CDOCAST Jewelry Continuous Casting Machine For making jewelry into wire, rod , plate

FAQ On Precious Metal Melting Furnace Purchase- Here you can find all the answers to the questions when you purchase precious metl casting machine

Video of Jewelry Vacuum Pressurized Casting Machine, you can learn more how the jewelry is cast

Platinum Centrifugal Casting Machine -Vacuum Centrifugal casting for platinum ,steel,& stainless steel