- Call Us: 008615168765707

- Mail Us: [email protected]

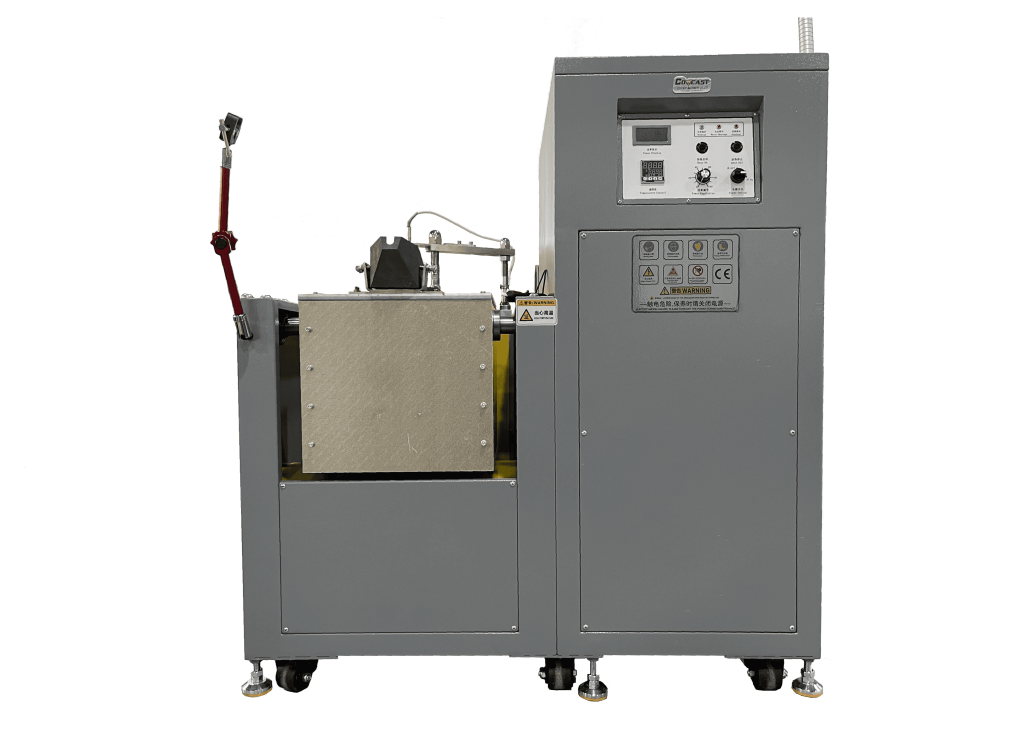

Small metal melting furnace for sale.Manual tilting & Motor Tilting is available.

Precision Meets Affordability: 10-300kg Gear-Driven Metal Melting Tilting Melting Furnace

Unlock exceptional value without compromising performance with our 10-300kg Gear-Driven Tilting Metal Melting Furnace. Designed for savvy investors and practical operators, this furnace delivers robust melting capabilities through a cost-effective gear reduction drive system. Ideal for small to medium-scale operations processing gold, silver, copper, and other non-ferrous metals, it combines efficiency, durability, and affordability in one powerful package.

① High-Efficiency Gear Reduction Drive System

Experience smooth, controlled tilting with our reliable *aluminum-housed gear reduction motor*. This system offers a budget-friendly alternative to hydraulic mechanisms while maintaining operational stability and simplicity. Its lightweight yet durable construction reduces overall costs without sacrificing performance.

② Optimized for Cost-Effective Melting

Designed with practicality in mind, this furnace delivers exceptional price-to-performance value, making it the ideal choice for startups, workshops, and investors seeking to maximize ROI without upfront heavy investment.

③ Precision Tilting with Curved Pouring Trajectory

The gear-driven tilting mechanism produces a predictable curved pouring path. Operators can achieve consistent results by aligning custom-designed receiving ladles or molds with this trajectory, ensuring safe and efficient metal transfer.

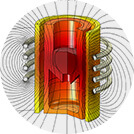

④ Advanced Medium Frequency Induction Technology

Benefit from rapid, uniform heating and precise temperature control with energy-efficient medium frequency induction power. This technology ensures minimal heat loss and optimal melting performance for a wide range of metals.

⑤ Durable Silicon Carbide Graphite Crucible

Built to withstand extreme temperatures and repeated use, the silicon carbide graphite crucible offers excellent thermal shock resistance and longevity, reducing maintenance costs and downtime.

▶ Specialized Ladle Compatibility: The curved pouring path requires matching ladles or molds designed to safely accommodate the tilt trajectory. Proper ladle selection ensures spill-free operation and enhances workplace safety.

▶ Operator Awareness: Users should familiarize themselves with the tilt mechanics and pouring arc to optimize safety and precision during operation.

30kg Motor Tilting Small Induction Melting Furnace:

30kg Motor Tilting Small Induction Melting Furnace:| Model | CDO-MTF15 | CDO-MTF25 | CDO-MTF35 | CDO-MTF45 | CDO-MTF70 | CDO-MTF90 | CDO-MTF110 | CDO-MTF160 | |

| MAX input power | 15KW | 25KW | 35KW | 45KW | 70KW | 90KW | 110KW | 160KW | |

| MAX input current | 23A | 36A | 51A | 68A | 105A | 135A | 168A | 240A | |

| Input voltage | Three-phase 340V ~420V 50/60Hz | ||||||||

| Oscillation frequency | 1K~20KHz | ||||||||

| Requirement of cooling water | Hydraulic pressure | ≥0.2Mpa | ≥0.3Mpa | ||||||

| Flow rate | ≥6L/Min | ≥20L/Min | |||||||

| Temperature of water | ≤45℃ | ||||||||

| Generator box | Weight | 28kg | 29kg | 52kg | 52kg | 57kg | 91kg | 99kg | 134kg |

| Volume | 51×28×49cm | 65×35×58 | 78×40×88 | 78×50×88 | |||||

| Transformer box | Weight | 35kg | 35kg | 35kg | 38kg | 52kg | 68kg | 95kg | 95kg |

| Volume | 62×30×53cm | 64×48×58 | 64×65×61 | ||||||

| Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | Model | Fe, ss | Cu, Au, Ag | Al, Al-alloy | |

| CDO-MTF15 | 3kg | 10kg | 3kg | CDO-MTF70 | 25kg | 80kg | 25kg | |

| CDO-MTF25 | 5kg | 20kg | 5kg | CDO-MTF90 | 40kg | 120kg | 40kg | |

| CDO-MTF35 | 10kg | 30kg | 10kg | CDO-MTF110 | 50kg | 150kg | 50kg | |

| CDO-MTF45 | 18kg | 50kg | 18kg | CDO-MTF160 | 100kg | 250kg | 100kg | |

| Remark: Above melting capacity sheet for general reference; Melting duration: When the crucible is hot,20~30min./workload; When the crucible is cold(first melt),40~50min./ workload. | ||||||||

1. Due to its simple structure, the biggest advantage of this small metal melting furnace is economical, which is affordable for starters.

2. Medium frequency metal melting furnace can be used for the melting of gold, silver, steel, stainless steel, brass, aluminium, lead, zinc, and almost all metals.

3. The IGBT Models’ design makes after-sales service very convenient. Customers only need to equip some commonly used power boards to perform simple maintenance, without the requirement for engineers to go onsite for maintenance, which greatly reduces the customer’s cost of use

4. The whole small metal melting furnace is only about one to two square meters, occupying a small space, and is the best choice for some starters

5. Compared with the traditional smelting method, the intermediate frequency smelting furnace is more environmentally friendly. There is no need to worry about the local government environmental protection department knocking on your door.

6. CDOCAST small metal melting furnace can work continuously for 24 hours or stop the furnace at any time without any influence on the furnace.

✔ Affordability: Lower initial investment and reduced maintenance costs compared to hydraulic systems.

✔ Reliability: The gear reduction mechanism offers simplicity and durability for long-term use.

✔ Adaptability: Suitable for a wide range of non-ferrous metals, including gold, silver, copper, and alloys.

✔ Ease of Use: Simple controls and consistent performance make it accessible for both experienced and novice operators.

1. Capacity Range: 10kg – 300kg (customizable based on metal type)

2. Tilting Mechanism: Gear Reduction Drive with Aluminum Housing

3. Power Supply: Medium Frequency Induction

4. Crucible Type: Silicon Carbide Graphite

5. Applications: Ideal for melting and casting non-ferrous metals such as gold, silver, copper, brass, and aluminum.

6. Perfect For: Small to medium-sized foundries, jewelry makers, precious metal recyclers, and budget-conscious investors seeking a reliable, economical melting solution.

Elevate your melting capabilities with a furnace that prioritizes efficiency, safety, and value.** Our Gear-Driven Tilting Melting Furnace is the smart choice for those who demand performance without the premium price tag.

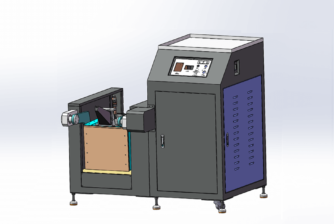

Furnace body can be customizd to motor tilting type and manual tilting type

The motor dumping device makes the operation safer and more efficient.

The furnace body adopts a manual tilting structure, which is simple and convenient, Economical.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST motor tilting metal melting furnace

Contact Our Engineer Team

CDOCAST provide you types of Electric Melting Furnace for you to choose when you want to invest in the furnace.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

The induction furnace is designed for melting small volumes of 100-350 Kg of non-ferrous and non-ferrous metals

CDOCAST precious casting machine is designed for casting customized sizes bar, rod,& plate for gold, silver and gold, it adopt the latest induction heating technology