How to Make Karat Gold Granules

How to Make Karat Gold Granules

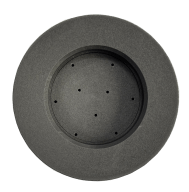

In precious metal refining and processing, granulation is a critical step for producing standardized raw materials such as gold and silver granules. This process involves melting the metal and allowing it to flow through fine holes at the bottom of a crucible, then cooling and solidifying it into uniform particles in water. However, due to significant differences in the physical properties of gold with varying purities—particularly between karat gold and pure gold—the design and use of the crucible, the core component of granulation equipment, must be tailored accordingly. Understanding these differences is essential for improving production efficiency, ensuring product quality, and minimizing losses. The following will guide you on how to make Karat Gold Granules:

1. Karat Gold vs. Pure Gold: The Root of All Differences

To grasp why crucibles differ, it’s important to first understand the fundamental characteristics of these two materials.

Karat Gold:

● Complex Composition: Karat gold is an alloy of gold and other metals (such as silver, copper, zinc, or nickel). Its purity is much lower than 24K pure gold, with common variants including 18K (75% gold) and 14K (58.5% gold).

● Higher and Broader Melting Range: The addition of alloying elements raises the melting point of karat gold above that of pure gold (1064°C), and melting occurs over a range rather than at a fixed point.

● Poor Fluidity: Molten karat gold has high viscosity and significantly poorer fluidity compared to pure gold, due to oxide formation, slag, and inherent physical properties.

● Prone to Oxidation and Slag Formation: Alloy metals oxidize more easily at high temperatures, forming slag that can clog small holes.

Pure Gold:

● High Purity:Typically refers to 24K gold or high-purity gold with Au99.9% or higher, containing minimal impurities.

● Fixed Melting Point: Has a distinct melting point (approximately 1064°C) and remains stable once molten.

● Excellent Fluidity:Molten pure gold is watery and exhibits exceptional fluidity and ductility, allowing it to pass easily through very fine holes.

● High Stability: Resists oxidation and produces almost no slag, resulting in a clean melt.

2. Key Differences in Crucible Design: Hole Size and Number

Based on these properties, crucible design focuses on addressing two core challenges: enabling viscous karat gold to flow smoothly and ensuring highly fluid pure gold flows evenly and controllably.

| Feature | Karat Gold Granulation Crucible | Pure Gold Granulation Crucible |

| Graphite Stopper Configuration | It is recommended to equip a stopper rod. Due to the poor fluidity of karat gold, the stopper rod should only be lifted to initiate granulation after the metal has fully melted. If granulation is attempted without a stopper rod while the metal is still melting, the remaining small amount of metal in the later stage may fail to drain completely due to insufficient gravitational force overcoming its own viscosity and flow resistance, potentially resulting in material retention and loss | The use of a stopper rod is flexible and optional. Thanks to the excellent fluidity of pure gold, multi-hole crucibles are typically equipped with a stopper rod to precisely control the start and end of granulation. However, when processing large pieces of material, the stopper rod can be removed to allow a “free-flow” mode, where the metal flows out automatically while melting, ensuring complete drainage without residue |

| Hole Size

|

Typically φ1.2-2.0mm | Typically φ0.8mm |

| Number of Holes | Small to medium capacity (e.g., 2-4kg): Prefer single-hole crucibles with a plug. Multiple holes reduce pressure per hole, hindering flow due to high surface tension. Larger capacities (e.g., 6kg+): Can use more holes to improve efficiency while ensuring flow. | Commonly uses “small holes, multiple holes” design. Excellent fluidity allows high throughput with uniform granules. |

| Taper of Graphite Bottom Plug | Steeper taper. A sharper angle creates a smoother flow path, reducing adhesion and resistance for viscous karat gold, preventing clogging. | Standard taper. Excellent fluidity ensures perfect granulation without the need for a steep taper. |

3. Additional Technical and Operational Considerations

Temperature Control:

● Karat Gold: Must be heated significantly above its melting point to reduce viscosity caused by high-melting-point components like silver and copper. Heating must be consistent and sustained throughout granulation, with slight power increases toward the end to compensate for heat loss and prevent clogging. However, excessive temperatures should be avoided to minimize oxidation and evaporation of alloy elements.

● Pure Gold: Only requires heating slightly above its melting point to maintain liquidity.

● Core Principle:Sustained heating throughout the granulation cycle—not just during melting—is critical for karat gold to avoid clogging.

4. Melt Treatment

● Karat Gold:Fluxing agents (e.g., borax) can be added during melting to help gather oxides and impurities into slag, which can be skimmed off to improve melt purity and reduce clogging risks.

● Pure Gold:Generally requires no fluxing agents.

5. Post-Processing

● Karat Gold:Granules may have rougher surfaces and may require additional acid washing or polishing to remove oxides.

● Pure Gold: Granules are typically bright, uniform, and consistent in quality.

6. Conclusion

In summary, selecting the right crucible for karat gold versus pure gold granulation is not merely a matter of size but a deep adaptation to the alloy’s physical properties.

For karat gold, the key to preventing clogging lies in the synergy between hole size and number, combined with a steeper Graphite Bottom Plug taper. The goal is to balance metal weight (determined by capacity and liquid level) with high surface tension. For small to medium capacities, a “large hole, single hole” strategy concentrates pressure to ensure flow. For larger capacities, more holes can be added to balance efficiency and flowability.

For pure gold, the inherent advantages of the material are leveraged through a “small hole, multiple holes” design to achieve both high efficiency and premium quality output.

Choosing the correct crucible and implementing appropriate temperature and operational controls are essential for ensuring smooth, efficient, and cost-effective operation in precious metal granulation production lines.