How to Cast Perfect Mirror Surface Gold Silver Bars

How to Cast Perfect Mirror Surface Gold Silver Bars

1. Why Don’t the Results Meet Expectations Even When Following the Manual?

Causes:

● Environmental variations: Parameters provided in the manual are typically based on laboratory or ideal conditions. Real-world production environments—such as gold purity, stability of factory power supply, equipment differences, and ambient temperature—can significantly impact casting outcomes.

● Gold purity and composition: Materials with different purities (e.g., 99.99% Au vs. 99.9% Au) have different melting points and flow characteristics, making standard parameters potentially ineffective.

Solutions:

● Keep detailed records of each debug session, including power settings, heating time, vacuum duration, cooling time, and delayed heating time. Adjust these parameters incrementally for optimal results.

● Consult the equipment manufacturer for model-specific recommendations.

2. Why Should New Graphite Molds Be Preheated?

Causes:

● Removing moisture and impurities: Graphite molds can absorb moisture or volatile substances during production, transportation, or storage. Preheating (typically to 200–300°C) evaporates these residues, preventing mold cracking or molten metal splatter.

● Ensuring consistent molding quality: A cold mold may cause premature solidification, leading to incomplete filling, flow marks, or porosity. Preheating ensures uniform mold temperature, improves metal fluidity, and enhances surface finish and dimensional accuracy.

Solutions:

● Preheat the mold for approximately 1minute before beginning the casting process.

3. Why Are There Graphite Residues on the Gold Bar Surface?

Causes:

● Graphite mold properties: Graphite is self-lubricating and may shed slightly at high temperatures, especially when the mold is new.

● New mold “break-in”: The first 1–5casts may produce more graphite dust until a dense oxide layer forms on the mold surface.

● Mold wear or damage: Micro-cracks from extended use can accelerate graphite particle shedding.

● Poor temperature control: Temperatures exceeding 1100°C can intensify graphite oxidation and shedding.

Solutions:

● Use the initial few casts for trial runs to “clean” the mold.

● Replace the mold once it reaches the end of its service life.

● Control the melting temperature between 1064°C and 1080°C to minimize graphite wear.

4. What Causes Bubbles on the Gold Bar Surface?

Causes:

● Prolonged heating causing localized overheating and gas release.

● Insufficient vacuum time or reduced vacuum pump efficiency, failing to remove all air from the mold.

● Unpreheated mold: Moisture or oil on a cold mold vaporizes upon contact with molten metal, forming bubbles.

Solutions:

● Reduce heating time appropriately.

● Extend vacuum time to ensure the mold reaches the required pressure before casting.

● Preheat the graphite mold for about 1 minute before adding material.

5. What Causes Dents on the Gold Bar Surface?

Causes:

● Slow cooling prolongs solidification, and excessive vacuum pressure may draw incompletely solidified metal, creating voids at the bottom.

● Inadequate vacuum time traps gas within the molten metal, resulting in porosity during solidification.

Solutions:

● Lower the chiller temperature to accelerate cooling.

● If cooling water temperature is adequate, extend the vacuum time.

6. What Causes Bulges on the Gold Bar Surface?

Causes:

● If bulges appear on the inner side of the bar, heating time may be insufficient, leaving unmelted gold.

● If bulges are on the outer side, excessive vacuum pressure may be pulling unsolidified metal upward.

● Slow cooling combined with high vacuum can extend solidification and cause top-side bulging due to suction.

Solutions:

● For inner bulges: Increase heating time.

● For outer bulges: Reduce vacuum pressure to below –20 kPa.

● Lower chiller temperature to speed up cooling.

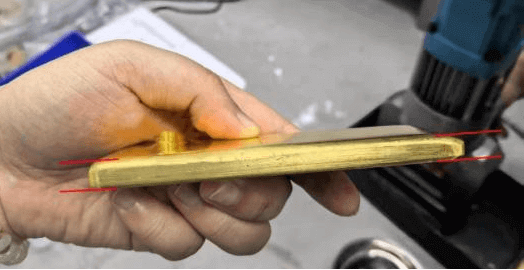

7. Why Are the Two Ends of the Gold Bar Different Thicknesses?

Causes:

● Uneven machine base:Improperly adjusted feet or ground settlement (>0.5° tilt) can cause uneven flow of molten metal.

● Inconsistent gold material:Mixing gold from different batches may lead to variations in fluidity.

Solutions:

● Use a precision level (accuracy 0.02 mm/m) to check the machine base and adjust the feet until the deviation at all four corners is ≤0.1 mm.

● Perform daily checks with a level before operation.

● Pre-melt and homogenize gold from different batches before casting.

8. Why Does the Gold Bar Surface Have Ripples?

Causes:

● Uneven mold temperature:Localized cold zones (e.g., mold edges) cause premature solidification and shrinkage patterns.

● Mixed gold materials:Using gold from different batches or purities can result in viscosity variations and flow layering.

● High impurity content: Oxidized impurities such as copper or silver can suspend in the melt and disrupt flow.

Solutions:

● Optimize the layout inside the mold to ensure even heating of graphite slots.

● Standardize raw materials: Use the same batch of gold for each cast and avoid mixing. Pre-purify recycled material (e.g., via electrolytic refining).

● Add a small amount of flux (e.g., ≤0.1% borax) for gold with impurities to improve fluidity.

9. What is the cause of this phenomenon on the surface of the gold bar?

Causes:

Gold bars may contain impurities such as lanthanum or titanium. These metals have a higher melting point and a lower density than gold. Therefore, during melting, they float to the surface, resulting in a non-lustrous appearance of the gold.

Solutions:

- Identify impurities (e.g., La, Ti) via spectrometry.

For La: Treat with dilute H₂SO₄ or HCl before re-casting.

For Ti: Treat with HF solution before re-casting.

- Alternative approach: Use new 9999 purity raw material for casting.

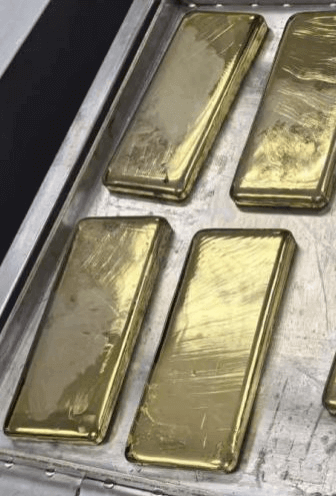

How to Cast Perfect Mirror Surface Gold Silver Bars? – Conclusion:

The quality of gold bar casting is influenced by multiple factors, including equipment parameters, mold condition, material purity, and process control. Addressing issues such as bubbles, dents, bulges, and thickness variations requires precise adjustments—optimizing equipment settings, calibrating machine levelness, standardizing mold pretreatment, and more. Through systematic debugging and standardized operations, high-quality gold bar production can be achieved consistently.