- Call Us: 008615168765707

- Mail Us: [email protected]

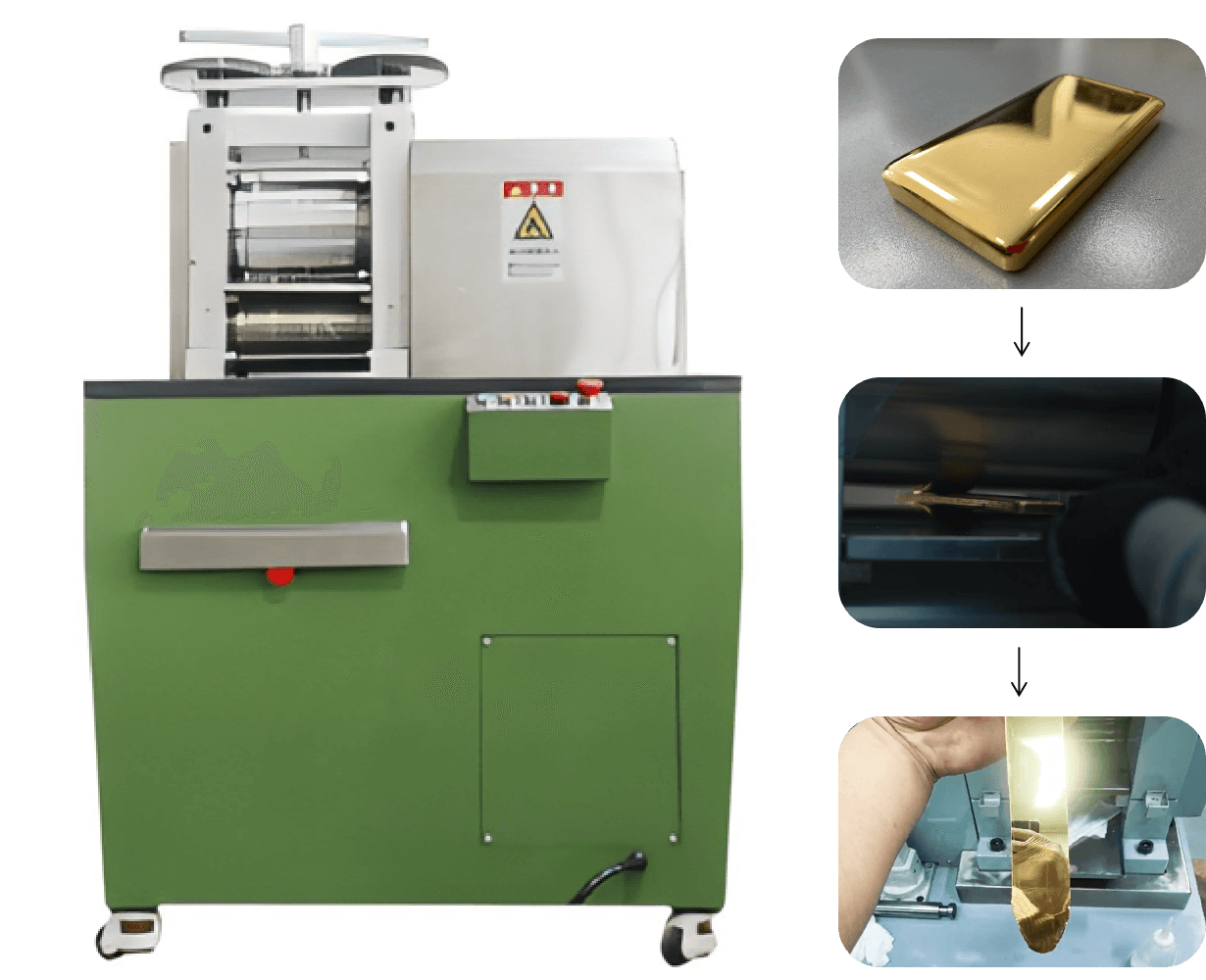

Buy the Most advanced Rolling Mill For Types Of Metals Strips

A metal strip rolling mill is a critical piece of industrial equipment, playing a central role in the precious metals and general metalworking industries. It processes metal strips—such as gold, silver, and copper—by passing them between one or more pairs of rotating rollers that apply precisely controlled pressure. This process induces planned plastic deformation, shaping the metal into precise strips, foils, or semi-finished products with specific thicknesses, widths, and surface finishes. This system is key to achieving high-precision, high-efficiency metal forming, directly determining the quality and consistency of the final product.

The fundamental principle of a strip rolling mill is **plastic deformation**. The drive system rotates the high-strength rolls in opposite directions, and the metal strip is fed into the gap between them. The mill applies immense vertical pressure—far exceeding the metal’s yield strength at room or elevated temperatures—through a hydraulic or mechanical system. This force causes the metal’s atomic lattice to slip, resulting in uniform thinning of its thickness, elongation in length, and a smooth surface finish. The entire process can be managed by an advanced CNC system that provides closed-loop control over pressure, speed, and tension, ensuring precise and stable deformation.

A high-performance metal rolling mill is a perfect integration of precision machinery and intelligent control, consisting of the following main components:

• Rolls: The core tools for deformation, directly determining product accuracy and surface quality. They are typically manufactured from ultra-high-strength, wear-resistant alloy materials like Cr12MoV, DC53, or Tungsten Steel, and undergo precision grinding and heat treatment to ensure long-term stability under high pressure and abrasive conditions.

• Frame: Acting as the “skeleton” of the entire machine, the frame is usually constructed from heavy-duty cast steel or welded steel plates, stress-relieved for stability. Its primary function is to provide the rigidity and strength needed to withstand enormous rolling forces, preventing any frame deflection from compromising rolling accuracy.

• Drive System: The “heart” of the mill, providing smooth and powerful rotational force to the rolls. This system typically includes high-performance motors, reduction gearboxes, and couplings, ensuring the rolls maintain constant torque at preset speeds for smooth startup and braking.

• Control System: The “brain” of the operation. Modern mills commonly use an automated control system combining a PLC (Programmable Logic Controller) with an HMI (Human-Machine Interface). Operators can use it to precisely set and monitor key parameters like working speed, rolling pressure, forward/reverse operation, and coiling tension, guaranteeing an automated and repeatable production process.

In the precious metals sector, the metal strip rolling mill is indispensable. It is used to roll cast gold and silver ingots into standard-thickness investment bars or thin sheets, and further into ultra-thin foils for applications in electronic circuits, decorative materials, and high-end crafts. Its value lies in its ability to produce high-quality products with precise dimensions, bright surfaces, and dense microstructure, all while offering high material utilization and mass-production capabilities, significantly enhancing the added value and brand image of precious metal products.

Cr12MoV |

DC53 |

Tungsten |

|

|---|---|---|---|

| Hardness | HRC 58-62 | HRC 60-64 | HRA 88-93 |

| Wear life | 1X | 1.3-1.5X | 5-8X |

| Impact resistance | ★★☆ | ★★★★ | ★★☆ |

| High temperature resistance | ≤300℃ | ≤400℃ | ≤800℃ |

| Cost | Low | Medium | High |

| Model | CDO-RM5.5 | CDO-RM7.5 | CDO-RM10 | CDO-RM15 | CDO-RM20 |

| Motor | 4kW | 5.5kW | 7.5kW | 11kW | 15kW |

| Voltage | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz |

| Roller Speed | 9.4m/min | 11.4m/min | 13.1m/min | 15.6m/min | 13.4m/min |

| Output Thickness | 25-0.1 mm | 25-0.1mm | 30-0.1 mm | 30-0.1mm | 45-0.15 mm |

| Roller Material | Cr12MoV | Cr12MoV | Cr12MoV | Cr12MoV | Cr12MoV |

| Roller Hardness | HRC 60-62 | HRC 60-62 | HRC 60-62 | HRC 60-62 | HRC 60-62 |

| Roller Size | Φ108x180mm | Φ132x180mm | Φ151x180mm/Φ151×250mm | Φ180x250mm | Φ200x250mm |

| Lubrication System | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated |

| Weight | 600kg | 950kg | 1200kg | 1700kg | 3000kg |

| Size(LxWxH) | 1200x640x1370mm | 1340x750x1420mm | 1430x760x1500mm | 1530x840x1600mm | 1740x900x1700mm |

| Roller material can be upgraded to DC53 or Tungsten | |||||

1: Use the high grade rollers to ensure the quality and stability of the machine.

2: The machine structure is heavy and stable, and the safety of operation is greatly improved.

3: Unique design dramatically improves the precision of binding.

4: Rolling different precious metals without loss.

5: The rolling mill can be customized according to customer needs.

6: The combination of multiple drivers and different drive structures has a moderate speed and can prevent interference.

Key Functions of a Metal Strip Rolling Mill

A metal strip rolling mill is far more than just a shaping tool; it is a transformative piece of industrial technology that enhances the very properties of metal. Its core functions deliver critical benefits for modern manufacturing:

1. Reshape and Resize Metal with Precision

The primary function of a rolling mill is to transform raw metal inputs—such as ingots and billets—into highly usable forms. This includes the production of precise sheets, strips, bars, and wires, all tailored to specific dimensional tolerances for downstream applications.

2. Enhance Material Properties and Performance

Rolling does more than change shape; it improves the metal’s internal structure and external qualities.

Grain Refinement: The process of compression breaks down and refines the metal’s internal grain structure. This can lead to significant improvements in key mechanical properties, such as strength and hardness (a phenomenon known as work hardening).

Hot vs. Cold Rolling Benefits:

Hot Rolling is highly effective for eliminating internal casting defects, creating a more uniform and ductile microstructure.

Cold Rolling is renowned for producing superior surface finish, tighter dimensional accuracy, and increased strength through strain hardening.

3. Maximize Production Efficiency and Output

Modern rolling mills are engineered for high-volume manufacturing. Continuous and semi-continuous rolling processes enable mass production at high speeds, reliably meeting the large-scale demands of global industries.

4. Achieve Energy Efficiency and Reduce Waste

Compared to subtractive methods like machining or cutting, rolling is a highly efficient forming process. It significantly reduces material waste (minimizing scrap) and generally consumes less energy per unit of output, contributing to more sustainable and cost-effective production

Rollers directly determine product quality and production efficiency. Choosing the right roll material, maintenance, and supporting processes are key to improving rolling mill performance!

The operation panel controls the working of the rolling mill.

The adjusting wheel is used to adjust the position of the roller.

CDOCAST Provide 1 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Metal Strips Rolling Mill

Contact Our Engineer Team

Designed for rolling gold, silver, copper, platinum, and aluminum into flawless strips or sheets, the CDOCAST Tungsten Carbide Rolling Mill delivers ultra-thin outputs down to 0.1mm with bubble-free surfaces, burr-free edges, and exceptional thickness uniformity.

CNC Controlled 4-Roller Precision Rolling Machine is particularly suitable for ultra-thin rolling of precious metals, copper alloys, aluminium alloys, and other materials. Its CNC system allows precise adjustment of rolling parameters to ensure uniform thickness.

CDOCAST Double Head Rolling Machine is designed for precision jewelry making and metal processing, ideal for reducing wire size and sheet thickness with ease. Perfect for working with gold, silver, copper, and other precious metals, it ensures high efficiency and durability to meet the demanding needs of jewelry production.

The Jewelry Wire Rolling Machine is a machine specifically designed for processing precious metal wires such as gold, silver, and platinum. Through multiple rolling processes, it gradually compresses metal billets (such as ingots and thick wires) to a target diameter (such as 1mm to 5mm) and improves the surface finish and mechanical properties of the wire