- Call Us: 008615168765707

- Mail Us: [email protected]

The Most advanced tilting silver melting furnace in china,Full automatic tilting proccess

Unlock unparalleled precision, efficiency, and convenience in your metal foundry with our advanced “30-100kg Motor-Driven Chain Tilt Silver Melting Furnace”. Designed for professionals who demand reliability and exactness in every pour, this furnace combines robust engineering with innovative features to streamline your melting process for silver, gold, copper, and other non-ferrous metals.

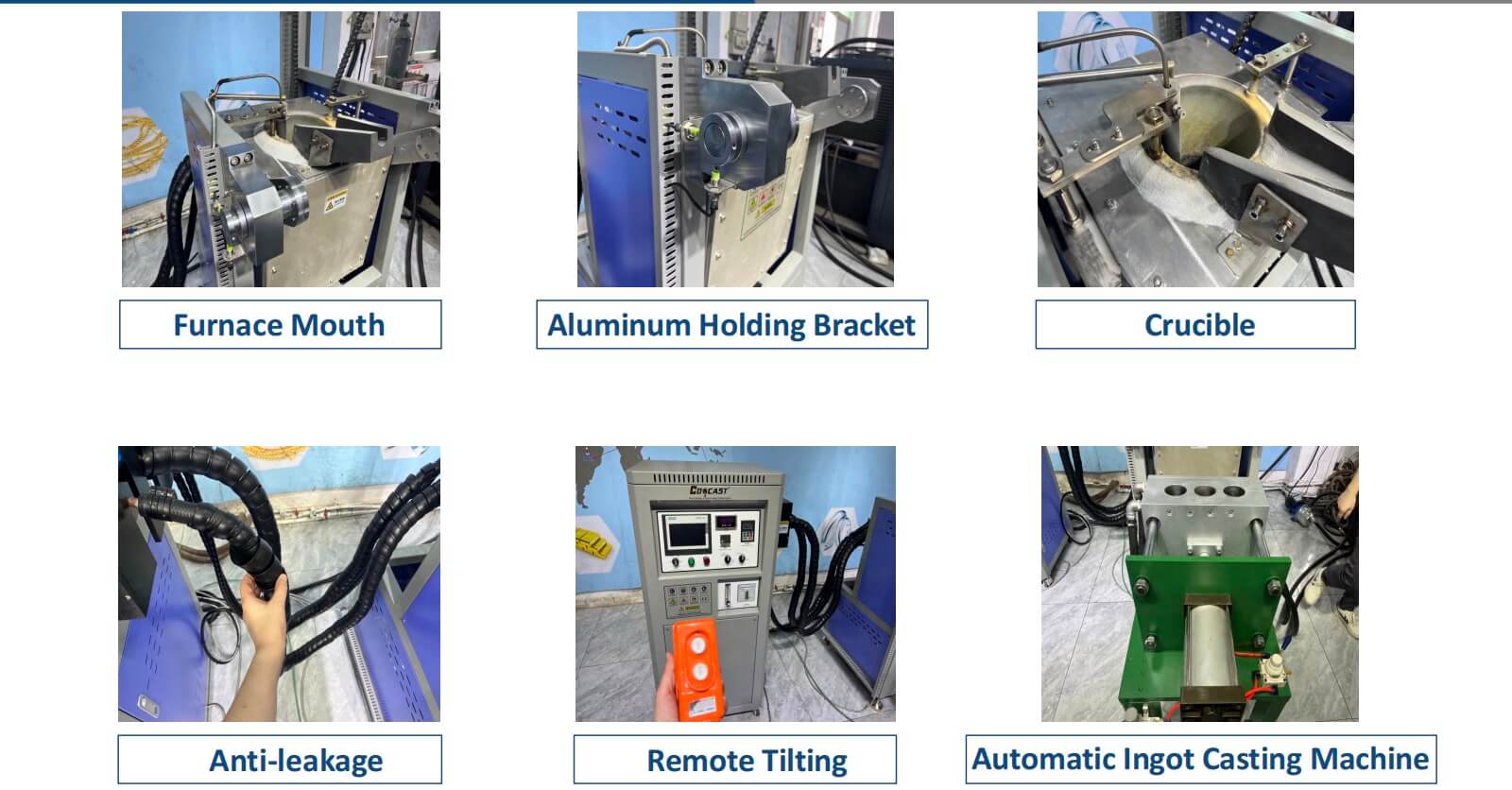

① Motor-Driven Chain Tilting Mechanism

Experience smooth, controlled, and consistent tilting with our unique “chain-driven system”. Unlike standard hydraulic or manual systems, the electric motor ensures a stable and repeatable tilt cycle, reducing operator fatigue and enhancing safety. The “fixed pouring point” allows for precise, tight casting into molds, minimizing metal spillage and maximizing yield.

② Optimized Height for Streamlined Operations

Our furnace features a “elevated structural design”, significantly taller than conventional hydraulic tilting furnaces. This intentional height advantage allows for seamless integration with **granulation barrels** or larger receiving molds positioned directly below the spout. Perfect for producing high-quality silver granules or bars with effortless workflow.

③ Advanced Medium Frequency Induction Technology

Achieve rapid, uniform melting with exceptional energy efficiency. Our medium frequency induction system ensures precise temperature control, perfect for a wide range of metals, including:

* Silver & Gold:** Ideal for jewelers, refiners, and bullion producers.

* Copper & Brass: Excellent for industrial casting and foundries.

* Other Non-Ferrous Alloys: Versatile enough for any specialized application.

④ Durable Silicon Carbide Graphite Crucible

At the heart of the furnace lies a premium “silicon carbide graphite crucible”, renowned for its exceptional thermal shock resistance and longevity. It withstands extreme temperatures, ensuring consistent performance and reducing long-term operating costs.

⑤ Built for Precision Casting & Granulation

The combination of the fixed pour point and elevated design makes this furnace the ultimate tool for:

* Tight-Precision Casting: Pour directly into intricate investment molds for detailed shapes.

* High-Volume Granulation: Efficiently produce consistent metal granules for industrial applications.

Upgrade your foundry with the furnace that’s engineered for perfection. Our Motor-Driven Chain Tilt Silver MeltingFurnace isn’t just a tool; it’s your partner in achieving flawless results, higher output, and a safer working environment.

↓↓↓

The Siemens operation panel is optional customized

| Model | CDO-CT25 | CDO-CT35 | CDO-CT50 | CDO-CT100 |

| Power | 25kw | 40kw | 50kw | 70kw |

| Voltage | 3P, 380V, 50/60hz | 3P, 380V, 50/60hz | 3P, 380V, 50/60hz | 3P, 380V, 50/60hz |

| Applicable metal | Gold, silver, copper | Gold, silver, copper | Gold, silver, copper | Gold, silver, copper |

| Max temperature | 1800℃ | 1800℃ | 1800℃ | 1800℃ |

| Melting time | 8-10min | 15-18min | 20-25min | 25-30min |

| Melting crucible material | Silicon carbide | Silicon carbide | Silicon carbide | Silicon carbide |

| Max capacity | Gold:40kg Silver:20kg |

Gold:50kg Silver:30kg |

Gold:90kg Silver:50kg |

Gold:180kg Silver:100kg |

| Dimension (LWH) | Main frame: 700*900*1200mm Furnace: 1000*800*1800mm |

Main frame: 650*600*1000mm Furnace: 650*830*1900mm |

Main frame: 650*600*1000mm Furnace: 650*830*1900mm |

Main frame:800*730*1500mm Furnace:880*1100*2240mm |

1. Graphite crucibles and quartz crucibles are available, thus enabling the melting of almost all non-ferrous and non-ferrous metals, and are particularly suitable for small foundries.

2. This small silver melting machine adopt advanced IGBT induction heating technology, power from 15kw-110Kw available, compared to KGPS induction heating, comes with energy saving effect of 20% .

3. PLC touch screen design is optional design, all the over-current, over-voltage, water shortage security alarm functions and temperature control can be set and display in the PLC, the operation is convenient and intuitive, the overall structure of the machine is aesthetically pleasing due to the reduced number of buttons in the control cabinet.

4. The crucible can be easily replaced without the need to dismantle the furnace to replace a broken crucible, just take it out. The whole process takes only 20 minutes

5. The silver melting furnace is equipped with a mobile trolley for loading the molds, and at the end of the melting process, the worker only needs to push the trolley to the furnace nozzle for pouring, which greatly increases the safety of the operation.

6. Customized graphite moulds are available to support the entire pouring process according to customer requirements.

Chain driven by the motor, can be operated remotely,achieves work efficiency and ensures the safety of the workers

The furnace can efficiently melt the metal raw materials, and the melted metal can be poured into the mold attached to the furnace body or mold holding car.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST 10kg-100kg chain titling silver melting furnace

Contact Our Engineer Team

CDOCAST provide you types of Electric Melting Furnace for you to choose when you want to invest in the furnace.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

The induction furnace is designed for melting small volumes of 100-350 Kg of non-ferrous and non-ferrous metals

CDOCAST precious casting machine is designed for casting customized sizes bar, rod,& plate for gold, silver and gold, it adopt the latest induction heating technology