- Call Us: 008615168765707

- Mail Us: [email protected]

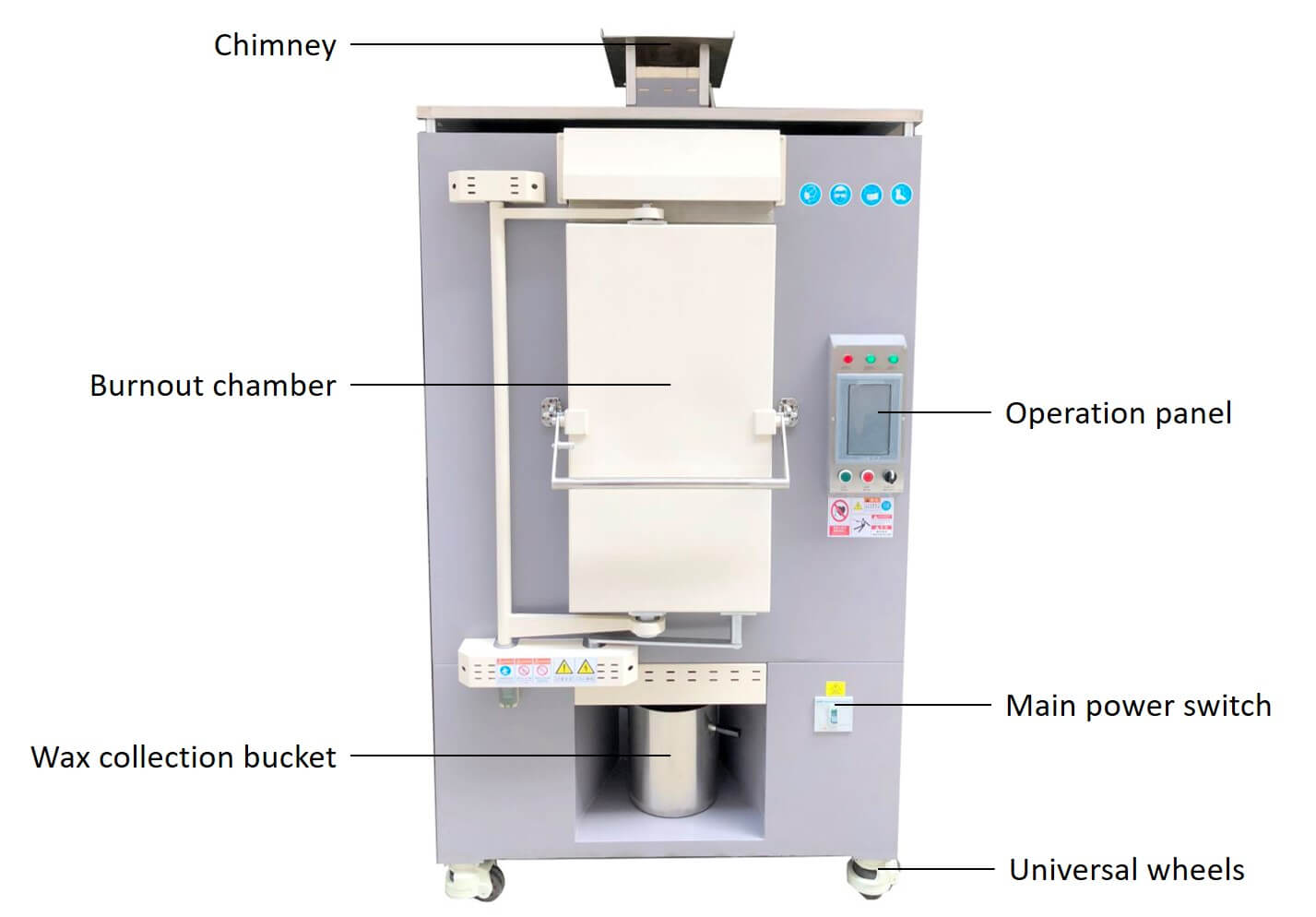

The most popular rotary burnout oven for sale

Wax rotary burnout oven is used for melting and flowing the wax in the plaster mold and a hollow plaster mold is obtained in the process of jewelry casting.

Special design for two-time burning; it will re-collect those not fully burnt during the dewaxing process and let them be burnt again for full combustion, and reducing the wax flavor in the environment as much as possible.

| Model | CDO-RB20 |

| Voltage | 3-phase 380V, 50/60 Hz |

| Power | 20 KW |

| Max temperature | 1000 °C |

| Working size | 700 * 700 * 700mm |

| Flask quantity | 32 pcs of 4*10 inch flask |

| Max height of the flask | 11 inch (280mm) |

| Number of heating layers | 2 layers |

| PLC touch screen | Equipped |

| Temperature control | Equipped |

| Outer dimensions | 1300 * 1100 * 2200mm |

| Weight | About 800 kg |

Feature:

1: CDOCAST burnout oven burning temperature is unformed and the temperature accuracy can be 2 degree with the temperature displace can be 0-1200C.

2: Max burning temperature is 900 Degree, and come with the temperature protection system, once the temperature is over than the set temperature, the power supply will be cut automatically, so can guarantee the machine and the castings can be well protect from damage.

3: Designed With second burning function, can Re-burning the exhaust gas in the furnace, Minimize air pollution and is an extremely environmentally friendly device.

4: Built-in two-layer rotating turntable, it can hold 40pcs 4*8 flask, and the single-layer load is about 50Kg, which is very suitable for large-scale jewelry manufacturers.

5: Rotate burnout oven comes with Touch screen editable program system design , with running data logging function, can store data running continuously for 30 days, support U disk CSV export data record file.

A: The internal standard dimensions of this rotary oven are 700mm (W) x 700mm (D) x 700mm (H). Yes, we support size customization based on your production needs.

A: The standard-sized rotary oven is equipped with 2 layers of rotating trays. With reasonable layout, it can simultaneously load up to 36 pcs of standard φ4 x 11-inch flasks, making it ideal for centralized dewaxing and firing of small to medium batch jewelry casting.

A: The maximum design temperature of this equipment can reach 1000°C, fully meeting the requirements for complete dewaxing and high-temperature firing of plaster molds for various precious metal casting. It is equipped with a temperature protection system; once the temperature exceeds the set point, the power will automatically cut off, ensuring the machine and castings are not damaged.

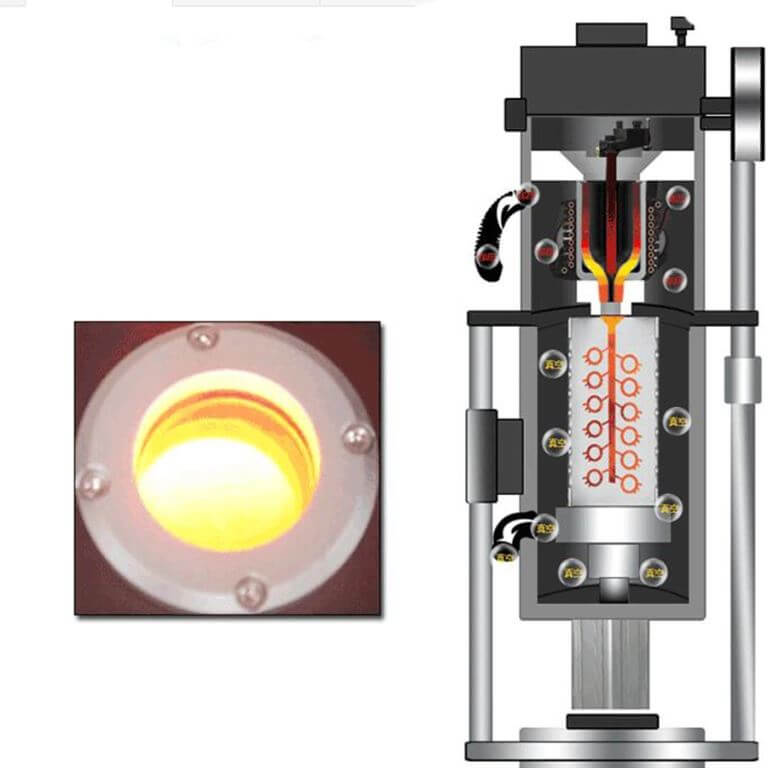

A: This rotary oven uses electric resistance heating. The furnace chamber is lined with heating elements on three sides to ensure even heating.

Working Principle: It provides precise temperature control through multi-zone electric radiant heating while driving the loaded part carrier to rotate at a constant speed, achieving dynamic and uniform heating of the parts. The melted wax flows smoothly out of the oven through a dedicated wax channel, preventing mold shell cracking due to wax expansion.

A: Yes, the rotation speed is adjustable. The equipment is equipped with a speed-controllable rotation mechanism. Users can set the optimal rotation speed according to the size of different molds, wax characteristics, and process stages (e.g., low speed for dewaxing, medium to high speed for firing).

A: The main advantages lie in the process improvements brought by the rotation function:

• More Thorough and Safer Dewaxing: The centrifugal force generated by rotation effectively guides the melted wax to flow smoothly out of the flasks, significantly reducing the risk of mold cracking caused by thermal expansion of the wax.

• More Uniform Heating: Rotation ensures all sides of the flasks and molds are heated evenly, avoiding local hotspots or insufficient heating, resulting in mold shells with stable quality.

• Improved Efficiency and Consistency: Capable of processing a large number of molds at once with high process controllability, making it very suitable for standardized production.

A: Our rotary oven adopts PLC touchscreen control system, allowing customers to freely set parameters such as heating temperature and time, enabling automated operation. It features operation data logging, supporting continuous storage of run data and export of data log files. It is also designed with a secondary combustion function that re-burns exhaust gases inside the furnace, minimizing air pollution and making it an extremely environmentally friendly device.

A: The furnace chamber is constructed from high-performance refractory ceramic fiber, offering good insulation and fast heating. The core rotating components are made of 310S stainless steel, ensuring long-term stable operation under high temperature and high load conditions.

A: The main common issues are:

• Mold Shell Cracking or Swelling: Usually caused by too rapid heating during the dewaxing stage. The solution is to use a gentler, low-temperature dewaxing curve and ensure the rotation function is properly activated.

• Castings with Porosity or Incomplete Metal Fill: This may be due to insufficient firing temperature or time, leaving the mold shell incompletely sintered or containing residual moisture. Check and ensure adequate firing temperature and holding time are reached.

• Residual Wax Ash After Dewaxing: Final firing temperature or time is insufficient. The temperature in the final firing stage should be increased and the holding time appropriately extended.

A: You can follow the following suggestions for maintenance:

• Regular Cleaning: Clean up wax drips and other debris inside the furnace chamber promptly after it has cooled down.

• Inspect the Rotation Mechanism: Periodically check if the fixing screws of the rotating rack are loose, if the bearings operate smoothly, and add high-temperature lubricant as required.

• Clean Internal Dust: Due to prolonged use and environmental factors, dust may accumulate inside the machine and on the mainboard. Regularly use compressed air to clean the mainboard and internal dust. (Perform this only 30 minutes after turning off the main power switch to avoid electric shock hazard.)

• Check Seals and Heating Elements: Observe if the furnace door seal is intact. Check heating elements (e.g., silicon carbide rods, resistance wires) for signs of aging or damage.

• Exhaust System: Regularly check that the exhaust pipes are clear and unobstructed.

A: The internal standard dimensions of this rotary oven are 700mm (W) x 700mm (D) x 700mm (H). Yes, we support size customization based on your production needs.

A: The standard-sized rotary oven is equipped with 2 layers of rotating trays. With reasonable layout, it can simultaneously load up to 36 pcs of standard φ4 x 11-inch flasks, making it ideal for centralized dewaxing and firing of small to medium batch jewelry casting.

A: The maximum design temperature of this equipment can reach 1000°C, fully meeting the requirements for complete dewaxing and high-temperature firing of plaster molds for various precious metal casting. It is equipped with a temperature protection system; once the temperature exceeds the set point, the power will automatically cut off, ensuring the machine and castings are not damaged.

A: This rotary oven uses electric resistance heating. The furnace chamber is lined with heating elements on three sides to ensure even heating.

Working Principle: It provides precise temperature control through multi-zone electric radiant heating while driving the loaded part carrier to rotate at a constant speed, achieving dynamic and uniform heating of the parts. The melted wax flows smoothly out of the oven through a dedicated wax channel, preventing mold shell cracking due to wax expansion.

A: Yes, the rotation speed is adjustable. The equipment is equipped with a speed-controllable rotation mechanism. Users can set the optimal rotation speed according to the size of different molds, wax characteristics, and process stages (e.g., low speed for dewaxing, medium to high speed for firing).

A: The main advantages lie in the process improvements brought by the rotation function:

• More Thorough and Safer Dewaxing: The centrifugal force generated by rotation effectively guides the melted wax to flow smoothly out of the flasks, significantly reducing the risk of mold cracking caused by thermal expansion of the wax.

• More Uniform Heating: Rotation ensures all sides of the flasks and molds are heated evenly, avoiding local hotspots or insufficient heating, resulting in mold shells with stable quality.

• Improved Efficiency and Consistency: Capable of processing a large number of molds at once with high process controllability, making it very suitable for standardized production.

A: Our rotary oven adopts PLC touchscreen control system, allowing customers to freely set parameters such as heating temperature and time, enabling automated operation. It features operation data logging, supporting continuous storage of run data and export of data log files. It is also designed with a secondary combustion function that re-burns exhaust gases inside the furnace, minimizing air pollution and making it an extremely environmentally friendly device.

A: The furnace chamber is constructed from high-performance refractory ceramic fiber, offering good insulation and fast heating. The core rotating components are made of 310S stainless steel, ensuring long-term stable operation under high temperature and high load conditions.

A: The main common issues are:

• Mold Shell Cracking or Swelling: Usually caused by too rapid heating during the dewaxing stage. The solution is to use a gentler, low-temperature dewaxing curve and ensure the rotation function is properly activated.

• Castings with Porosity or Incomplete Metal Fill: This may be due to insufficient firing temperature or time, leaving the mold shell incompletely sintered or containing residual moisture. Check and ensure adequate firing temperature and holding time are reached.

• Residual Wax Ash After Dewaxing: Final firing temperature or time is insufficient. The temperature in the final firing stage should be increased and the holding time appropriately extended.

A: You can follow the following suggestions for maintenance:

• Regular Cleaning: Clean up wax drips and other debris inside the furnace chamber promptly after it has cooled down.

• Inspect the Rotation Mechanism: Periodically check if the fixing screws of the rotating rack are loose, if the bearings operate smoothly, and add high-temperature lubricant as required.

• Clean Internal Dust: Due to prolonged use and environmental factors, dust may accumulate inside the machine and on the mainboard. Regularly use compressed air to clean the mainboard and internal dust. (Perform this only 30 minutes after turning off the main power switch to avoid electric shock hazard.)

• Check Seals and Heating Elements: Observe if the furnace door seal is intact. Check heating elements (e.g., silicon carbide rods, resistance wires) for signs of aging or damage.

• Exhaust System: Regularly check that the exhaust pipes are clear and unobstructed.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST rotary burnout oven

Contact Our Engineer Team

How To Purchase A Most Suitable Gold Testing Machine to test the purity of your gold and silver, Click here

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

Video of Jewelry Vacuum Pressurized Casting Machine, you can learn more how the jewelry is cast

Platinum Centrifugal Casting Machine -Vacuum Centrifugal casting for platinum ,steel,& stainless steel