- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the most advanced Precious Metal Aqua Regia Refining Equipment. Inquiry Now.

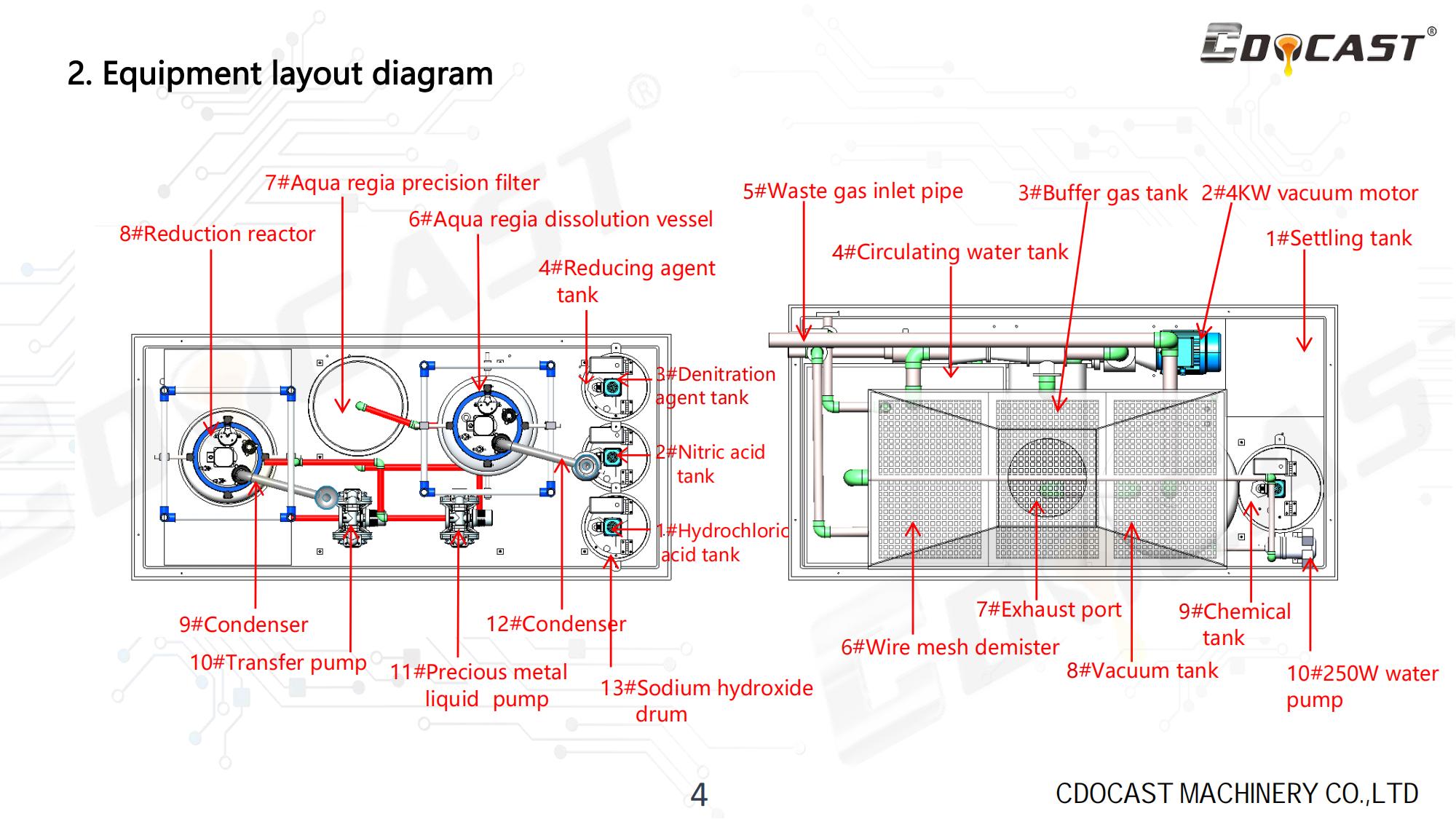

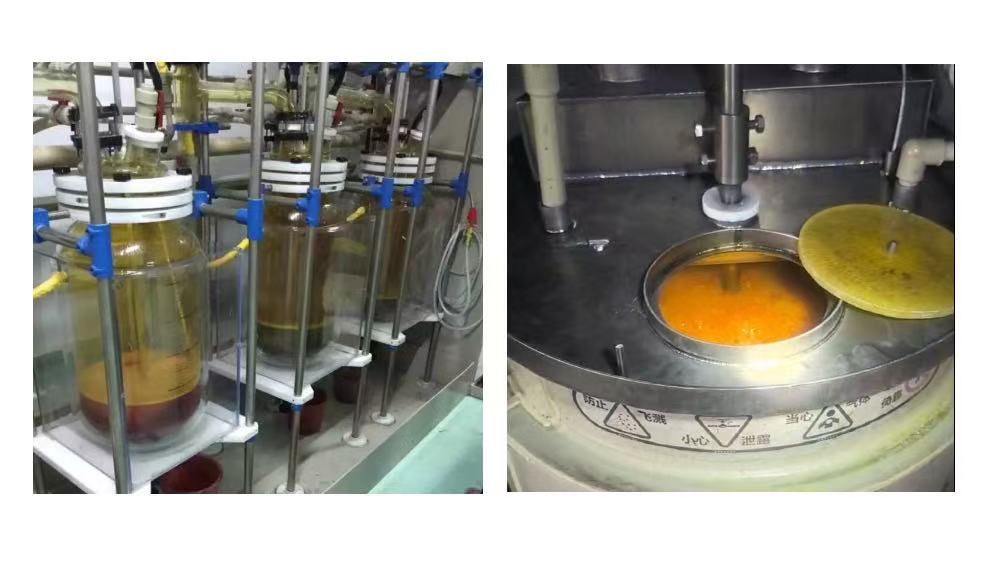

Precious Metal Aqua Regia Refining Equipment is used to purify metals like gold, silver, platinum, and palladium from scrap, ores, or industrial byproducts. Aqua regia, a mixture of concentrated nitric acid and hydrochloric acid (typically in a 1:3 ratio), is used to dissolve gold, platinum, and other precious metals. The dissolved metals are then selectively precipitated or reduced, followed by purification steps such as filtration, washing, and smelting to obtain high-purity metals. This method is effective for small-scale refining or recycling scrap.

The aqua regia method is a widely used chemical process for dissolving and refining precious metals, particularly gold (Au) and platinum (Pt). Aqua regia, meaning “royal water” in Latin, is a highly corrosive mixture of concentrated nitric acid (HNO₃) and hydrochloric acid (HCl), typically in a 1:3 volume ratio.

Advantage: simple the process, low technology investment, high gold recovery rate.

Notice: During the Aqua Regia Refining process, some harmful gases(mainly Sulfide waste gas)will be produced due to chemical reaction. So it shall be approved by the local environmental protection bureau before using.

Process Steps:

1.Dissolution: The scrap metal is dissolved in aqua regia.

Gold reacts to form chloroauric acid (HAuCl₄).

2.Precipitation: A reducing agent (e.g., sodium metabisulfite) is added to precipitate pure gold.

3.Filtration & Washing: The gold powder is filtered and washed to remove impurities.

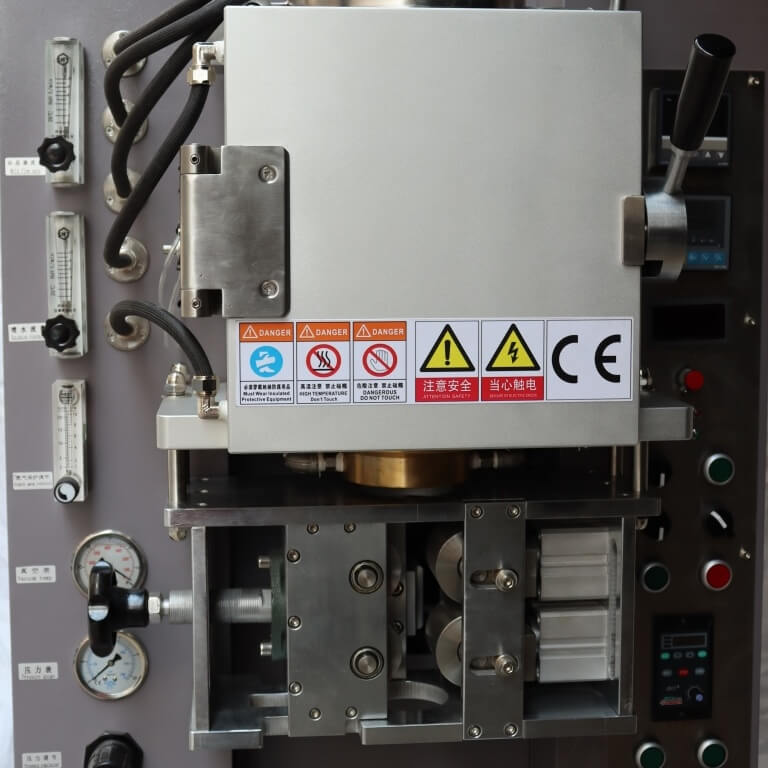

4.Melting: The purified gold is melted into bars.

⚠ Safety: Aqua regia releases toxic gases (e.g., NO₂, Cl₂) and must be used in a fume hood with proper PPE.

For more details on gold refining, please click this link to visit the Gold Refining Blog

For more details on silver refining, please click this link to visit the Silver Refining Blog .

If you want to pulverize gold or silver materials into flake for purification, you can click this link to learn about CDOCAST Metal Flake Making Machine

Gold and Silver Aqua Regia Refining Equipment

| Feature | Aqua Regia Method | Electrolysis Method |

| Process Type | Chemical dissolution | Electrochemical process |

| Chemicals Used | HNO₃ + HCl (3:1 ratio) | Acidic/alkaline electrolyte (e.g., H₂SO₄) |

| Suitable Metals | Au, Pt, Pd | Au, Ag, Pt (varies by setup) |

| Purity Achievable | 99.5%-99.99% | 99.9%-99.999% |

| Speed | Fast (hours) | Slow (days for large batches) |

| Energy Consumption | Low (room temp.) | High (requires electricity) |

| Waste Production | Toxic fumes (NOx, Cl₂), acidic waste | Less chemical waste, metal sludge |

| Safety Concerns | Highly corrosive, toxic gases | Electrical hazards, electrolyte handling |

| Equipment Cost | Low (glassware, fume hood) | High (power supply, specialized cells) |

| Scalability | Suitable for small-medium batches | Better for industrial-scale production |

| Byproduct Recovery | Requires additional steps | Easier (e.g., anode slime collection) |

| Skill Requirement | Moderate (acid handling experience) | High (electrochemistry knowledge) |

1.High Efficiency – Effectively dissolves gold, platinum, and palladium, even in small quantities.

2.Versatility – Suitable for refining scrap jewelry, electronic waste, and industrial catalysts.

3.Precision – Allows selective precipitation of pure metals (e.g., gold can be isolated using reducing agents like sodium metabisulfite).

4.Cost-Effective – Lower initial setup cost compared to electrolytic systems.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Precious Metal Aqua Regia Refining Equipment

Contact Our Engineer Team

Gold wire, silver wire in the jewelry industry and its electronic industry is very common and important product,Let’s talk about the drawing process of gold and silver wire in detail.

CDOCAST launched a new gold Smelter which is manual tilting, This small coreless induction melting furnaces capable of melting ferrous, non-ferrous, precious metals…..

videos Continuous Casting Machine for precious metals . Click the link you can learn more through the video

Small Upward Continous Casting Machine for silver pipe casting , click to learn more about it