- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the Most advanced Rolling Mill For Types Of Metals Sheet& Wire

Every CDOCAST wire rolling mill is built around a synergy of robust components, ensuring reliability and precision at every stage.

Precision Rolls: The heart of the machine. Our rolls are crafted from ultra-high-strength, wear-resistant alloys like Cr12MoV, DC53, or Tungsten Steel, ensuring they maintain their profile and finish through prolonged use, directly guaranteeing the quality of your wire.

Robust Machine Frame: Constructed from heavy-duty materials, the frame provides the foundational rigidity required to withstand immense rolling forces without deflection, ensuring consistent wire geometry and operational stability.

Powerful Drive System: A high-torque system, comprising motors and gearboxes, delivers smooth and powerful rotation to the rolls, enabling steady deformation of even the toughest precious metal alloys.

Automated Control System: Modern efficiency is driven by automation. Our intuitive control system allows operators to precisely regulate critical parameters like speed, pressure, and tension, ensuring repeatable results and simplified operation.

Automatic Coiling System: The final touch for productivity. This system neatly winds the finished wire into uniform, manageable coils, ready for the next stage of production or shipment, while minimizing tangling and surface damage.

Superior Output Quality: Achieve a mirror-like surface finish and consistent diameter that meets the most stringent standards of the jewelry industry.

Enhanced Material Properties: Improve the tensile strength and ductility of your wire through controlled work hardening, resulting in a more durable and workable final product.

Unmatched Efficiency: The continuous, multi-pass rolling process and automated coiling significantly boost production output, reducing labor costs and increasing your manufacturing throughput.

Uncompromising Durability: Built with premium components and a focus on longevity, our mills are an investment that delivers reliable performance for years to come.

Cr12MoV |

DC53 |

Tungsten |

|

|---|---|---|---|

| Hardness | HRC 58-62 | HRC 60-64 | HRA 88-93 |

| Wear life | 1X | 1.3-1.5X | 5-8X |

| Impact resistance | ★★☆ | ★★★★ | ★★☆ |

| High temperature resistance | ≤300℃ | ≤400℃ | ≤800℃ |

| Cost | Low | Medium | High |

✅ High-precision rolling

Using Cr12MoV or tungsten steel rollers, tolerances can reach ±0.01mm, making it suitable for precision industries such as jewelry and electronics.

Capable of processing round, square, flat, and other shaped wires.

✅ Multi-pass continuous forming

Adjustable roller gap allows for staged diameter reduction to prevent metal cracking.

✅ Energy-saving and efficient

Electric/hydraulic drive improves efficiency by 50% compared to traditional hammer forging, with material loss is less than 3%.

| Model | CDO-RM5.5 | CDO-RM7.5 | CDO-RM10 | CDO-RM15 | CDO-RM20 |

| Motor | 4kW | 5.5kW | 7.5kW | 11kW | 15kW |

| Voltage | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz | 380V, 3P, 50/60Hz |

| Roller Speed | 15m/min | 18.3m/min | 21m/min | 25m/min | 13.4m/min |

| Wire Size | 7*7-1*1mm | 7*7-1*1mm | 14*14-6*6mm | 18.5*18.5-11*11mm | 23.5*23.5-17*17mm |

| Roller Material | Cr12MoV | Cr12MoV | Cr12MoV | Cr12MoV | Cr12MoV |

| Roller Hardness | HRC 60-62 | HRC 60-62 | HRC 60-62 | HRC 60-62 | HRC 60-62 |

| Roller Size | Φ108x228mm | Φ132x228mm | Φ151×250mm | Φ180x250mm | Φ200x250mm |

| Lubrication System | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated | Bearing Bush Grease Lubricated |

| Weight | 600kg | 950kg | 1200kg | 1700kg | 3000kg |

| Size(LxWxH) | 1200x640x1370mm | 1340x750x1420mm | 1430x760x1500mm | 1530x840x1600mm | 1740x900x1700mm |

| Roller material can be upgraded to DC53 or Tungsten | |||||

1. High-Grade Alloy Rollers for Uncompromising Quality

We utilize premium forged alloy rollers, renowned for their exceptional wear resistance and thermal stability. This choice directly translates to superior surface finish on your precious metal wires, extended intervals between re-grinding, and consistent dimensional accuracy over long production runs, ensuring ultimate product stability.

2. Robust & Heavy-Duty Construction for Maximum Stability

The mill features a massively rigid, one-piece frame construction. This heavy-duty design effectively absorbs and dampens the high dynamic loads generated during rolling, virtually eliminating frame deflection and vibration. The result is not only enhanced operational safety but also significantly improved wire dimensional consistency and a longer machine service life.

3. Precision-Guiding System for Flawless Wire Geometry

Our proprietary, uniquely engineered wire guiding and alignment system is key. It meticulously centers the wire entering each roll stand, dramatically reducing tolerances and preventing common issues like twisting or asymmetrical deformation. This innovative design is what guarantees the exceptional geometric precision and uniformity of your final wire product.

4. Optimized for Zero-Contamination Processing

The entire deformation path, from entry guides to the rolls themselves, is crafted from dedicated, non-reactive materials and finished to a mirror-like polish. This meticulous attention to detail ensures that you can roll gold, silver, and platinum in succession without cross-contamination and with virtually zero material loss, preserving the full value of your precious metals.

5. Tailored Solutions for Your Specific Production

We understand that one size does not fit all. Our rolling mills are highly customizable, with options to specify the number of rolling stands, final wire diameter range, motor power, and the level of automation. This flexibility allows us to deliver a perfect solution, whether for a specialized jewelry workshop or a large-scale industrial refinery.

6. Advanced, Interference-Free Drive Technology

The machine employs a sophisticated combination of multiple independent drivers and a meticulously calibrated gear train structure. This advanced configuration delivers perfectly moderate and controlled rolling speeds, crucial for the delicate nature of precious metals. Furthermore, this design inherently prevents torsional vibration and power transmission interference, ensuring exceptionally smooth operation and protecting the integrity of your fine wires.

Rollers directly determine product quality and production efficiency. Choosing the right roll material, maintenance, and supporting processes are key to improving rolling mill performance!

The operation panel controls the working of the rolling mill.

The adjusting wheel is used to adjust the position of the roller.

CDOCAST Provide 1 year warranty, and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Jewelry Wire Rolling Machine

Contact Our Engineer Team

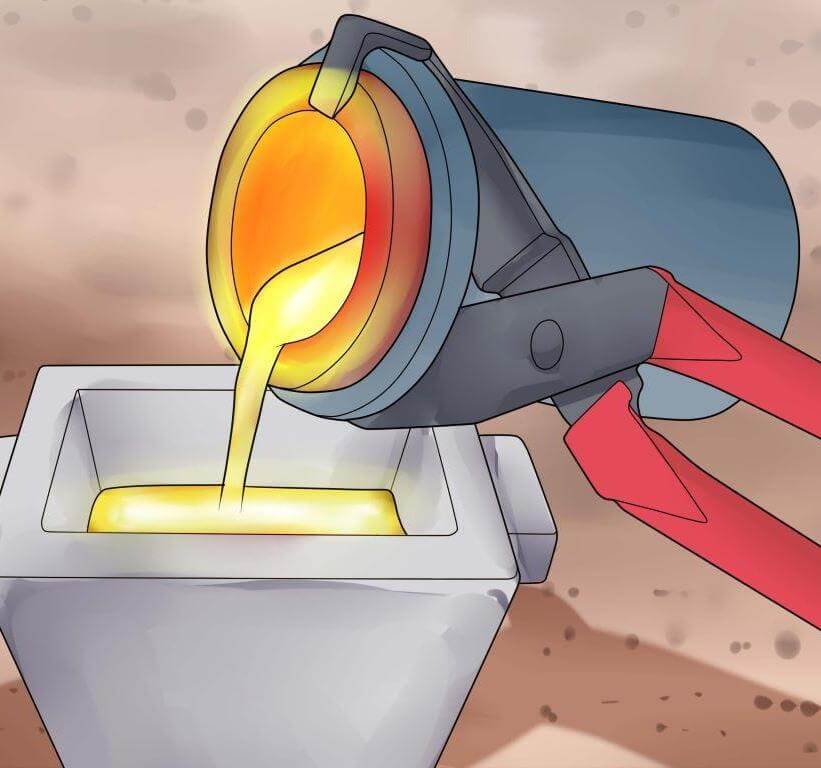

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….