- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the Most Efficient Jewelry Polishing Machine

CDOCAST Jewelry Polishing Machine is specifically designed for processing various metals (gold, silver, copper, etc.) and hard synthetic materials, meeting polishing demands across multiple industries. Polishing Machine delivers highly efficient surface finishing for metals, imparting exceptional surface smoothness to precious metals, jewelry, and precision components.

In jewelry manufacturing, surface polishing directly determines product aesthetics and commercial value. Traditional manual polishing is inefficient, inconsistent, and struggles with complex geometries. CDOCAST introduces multiple intelligent systems — Vibration Polishing Machine, Centrifugal Polishing Machine, Dry/Wet Eddy Current Grinding Polishing Machine, etc — engineered to overcome industry challenges and elevate your productivity!

① Vibration Polishing Machine (Master of Complex Structures): It is designed for porous, hollow, and intricate jewelry, solving polishing challenges in hard-to-reach areas like earring backs, chain links, and relief details. Ideal for:

② Centrifugal Polishing Machine (High-Speed Expert for Precision Parts): Optimized for ultra-smooth, mirror finishes on high-value micro-components:

③ Dry/Wet Eddy Current Grinding Polishing Machine (Gentle Solution for Curved Surfaces): Specialized for scratch-sensitive curved jewelry, preserving plated/enamel finishes:

Vibration Polishing Machine:

| Model | CDO-VPM40 | CDO-VPM60 | CDO-VPM80 |

| Voltage | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz |

| Power | 550W | 750W | 750W |

| Capacity | 40L | 60L | 80L |

| Rotation rate | 1450R/Min | 1450R/Min | 1450R/Min |

| Size | φ50x62mm | φ64x62mm | φ80x75mm |

| Weight | 50kg | 85kg | 100kg |

Centrifugal Polishing Machine:

| Model | CDO-CPM30 | CDO-CPM40 | CDO-CPM50 |

| Voltage | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz |

| Motor power | 2.2 KW | 2.2 KW | 3 KW |

| Total capacity | 30L | 40L | 50L |

| Polishing tank capacity | 4*7.5L | 4*10L | 8*6.2L |

| Polishing tank size | φ175**275mm | φ175*355mm | φ175*235mm |

| Rotation rate | 1800 rpm | 1800 rpm | 1800 rpm |

| Outer Dimensions | 1080*960*1400mm | 1180*960*1400mm | 1280*960*1400mm |

| Weight | 600kg | 650kg | 720kg |

Wet Eddy Current Grinding Polishing Machine:

| Model | CDO-GPM18-1 | CDO-GPM18-2 | CDO-GPM18-3 | CDO-GPM36-1 | CDO-GPM36-2 | CDO-GPM36-3 |

| Voltage | 220V, 1 Phase, 50Hz | 220V, 1 Phase, 50Hz | 220V, 1 Phase, 50Hz | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz |

| Motor power | 0.75 KW | 2*0.75 KW | 3*0.75 KW | 2.2 KW | 2*2.2 KW | 3*2.2 KW |

| Rated volume | 18L | 2*18L | 3*18L | 36L | 2*36L | 3*36L |

| Working volume | 14L | 2*14L | 3*14L | 28L | 2*28L | 3*28L |

| Outer Dimensions | 690×850×1440mm | 1170×850×1440mm | 1680×850×1440mm | 880×780×1440mm | 1480×780×1440mm | 2120×780×1440mm |

| Weight | 140kg | 235kg | 330kg | 220kg | 370kg | 530kg |

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Jewelry Polishing Machine

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

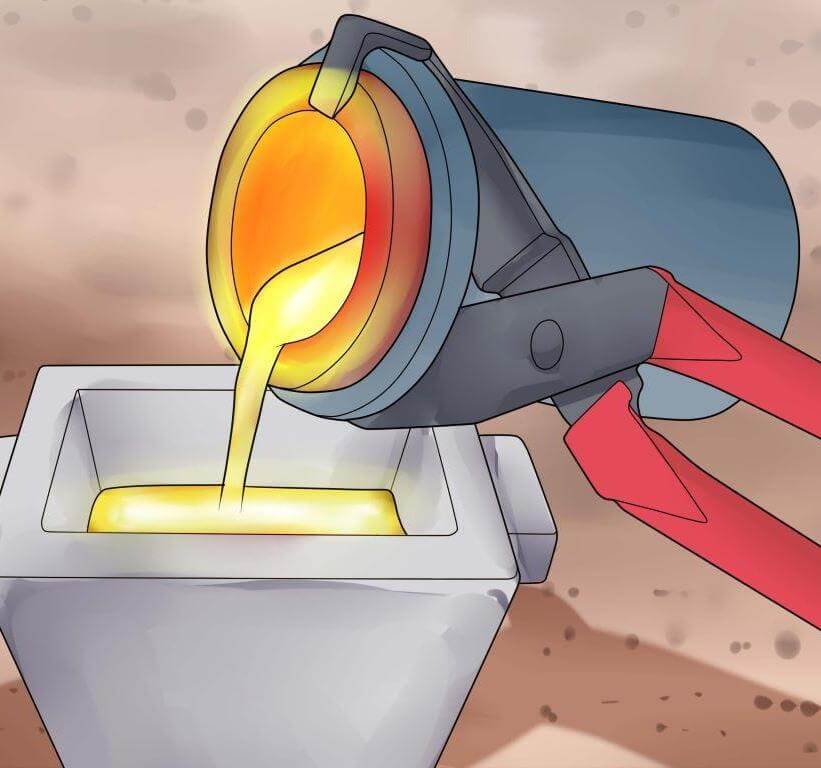

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….