Why did my induction coil burn out during use and what is the correct usage of induction coil?

Induction coils frequently burn out during use. Below are the primary causes and solutions:

1. Insufficient Cooling

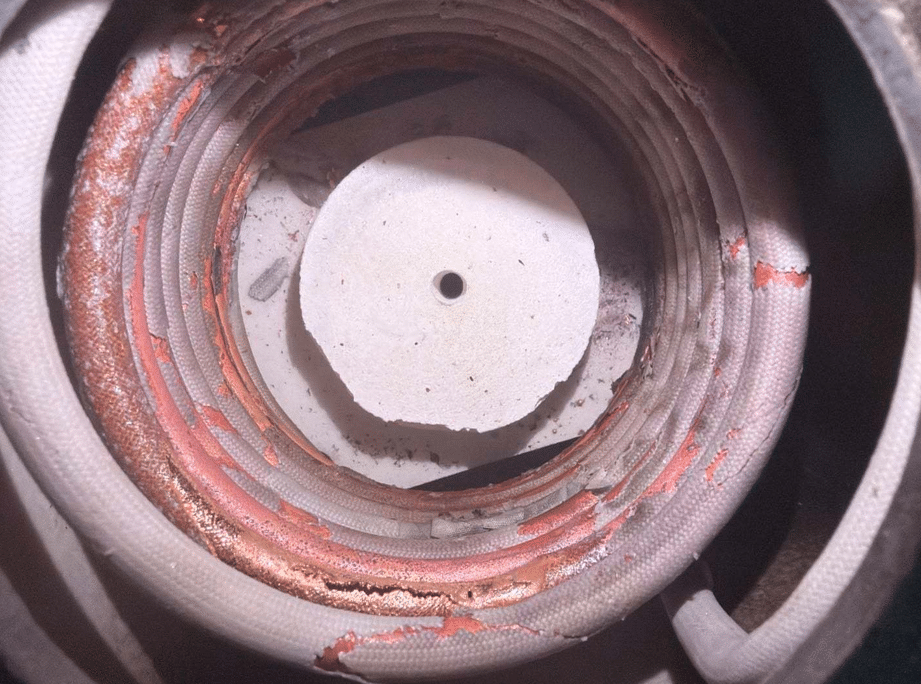

(Coil damage due to insufficient cooling typically appears as complete damage of the coil’s protective casing.) The burnt coil is like the following picture

- User forgets to running chiller before heating. This operation will cause the coil to work without cooling, resulting in overheating and damage. Users must always remember: “Cooling first, then power and heating on.”

- Blocked cooling system due to impurities in the water can obstruct flow in the chiller hoses or the coil’s copper tubes, leading to overheating.

Solution: Before heating, turn on the chiller in advance to check for smooth water circulation. Keep the cooling water tank clean to prevent impurities from entering the water circulation system. Use compressed air to clear any blockages in the hoses. If possible, use distilled or drinking water instead of regular tap water, and install filter connectors in the hoses. - Low water flow rate and water pressure can cause the coil to overheat. The required cooling specifications vary by equipment—user should consult it with the manufacturer before operation.

- Incorrect pipe connection, such as reversing the inlet and outlet hoses, results in no cooling water flow in the induction coil, which can lead to the overheating of coil.

2. Wrong Crucible Usage

- Placing a hot crucible into the coil after heating, especially when the cooling system has stopped, can melt or burn the coil.

Correct Usage: Allow hot crucibles to cool naturally outside the machine after all equipment has been shut down. - Always ensure the crucible is inside the coil during heating. Operating at high power without a crucible in place is extremely dangerous, as nearly all energy dissipates into the coil itself, which can burn out within minutes.

3. Electrical and Insulation

(Damage from these causes often appears as localized holes or arcs puncturing the copper tube.) The burnt coil is like the following picture.

- Mismatched voltage or frequency between the user’s power supply and the machine’s specifications can make the coil burned. User need to confirm all electrical parameters before purchasing equipment.

- Insufficiently dried furnace lining can release steam or chemicals under high temperatures, which may condense on the coil and cause short-term arcing, eventually damaging the furnace lining.

Solution: Gradually dry the furnace lining by running the machine at 300–500°C before full operation. - Inadequate insulation thickness on the coil can lead to arcing between turns. When applying insulation, follow the manufacturer’s guidelines to ensure each turn is sufficiently protected.