- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the Most advanced Hydraulic Shearing Machine For Types Of Metals

Core Components for Reliable Operation

The machine is built around several key subsystems that work in unison:

• Robust Machine Frame: Provides structural integrity and stability during operation.

• Precision Cutting Device: The heart of the machine, responsible for clean and accurate cuts.

• Secure Clamping Device: Holds the material firmly in place to prevent slippage.

• Automatic Pushing Device: Ensures consistent and hands-off material feeding.

• High-Pressure Hydraulic Station: Delivers the powerful force required for smooth cutting.

• Intelligent Electrical Control System: Allows for easy operation and parameter adjustments.

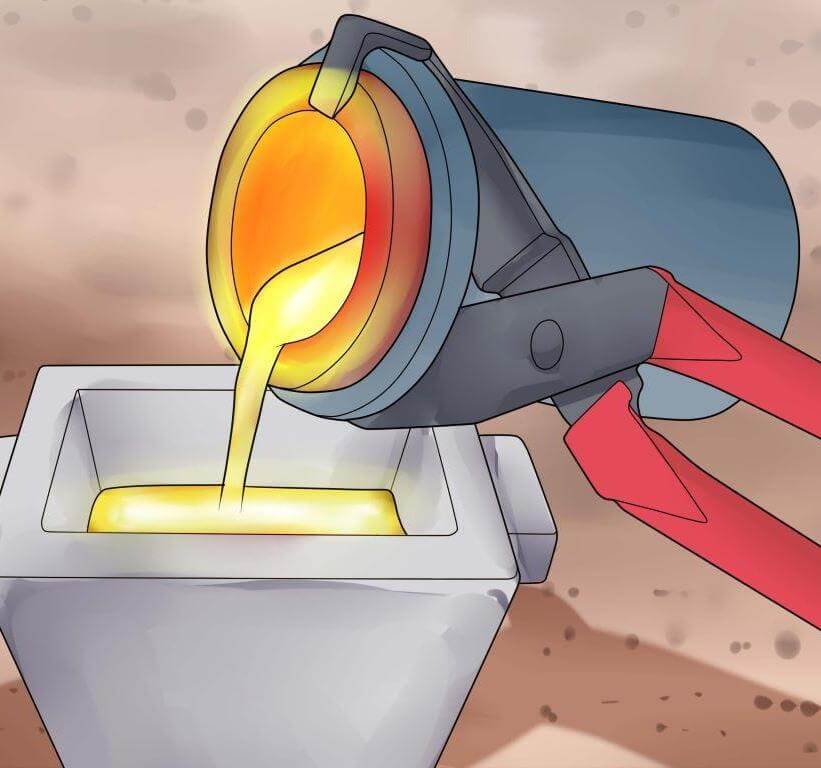

How It Works: Automated & Efficient Cutting Process

Our hydraulic shearing process is designed for simplicity, safety, and consistency:

• Loading: The operator places a metal plate (e.g., a silver plate) into the material slot.

• Initiating the Cycle: Pressing the automatic start button activates the feeding cylinder, which pushes the plate toward the cutting area.

• Precise Feeding & Clamping: The system feeds the material until the preset cutting length is reached. A clamping device then securely holds the plate in position.

• Clean Cutting Action: The upper blade descends to make a clean cut. The cut fragment falls through a square hole directly into a collection tank below.

• Automatic Reset: Upon completion, the system automatically resets, and the feeding device advances the material for the next cycle, enabling continuous operation.

Key Engineering Features for Superior Performance

• Adjustable Cutting Length

The machine allows operators to easily set and adjust the cutting length to meet specific production requirements, offering exceptional flexibility.

• Optimized Blade Design for Longevity

The machine utilizes flat-edged blades, with the upper blade precision-ground to a specific inclination angle. This innovative design ensures the blade contacts the material gradually, shearing from one end to the other rather than across the entire surface at once.

• Key Benefit: This significantly reduces stress on the cutting blades, minimizing wear and tear and substantially extending their service life, which lowers long-term operating costs.

Advanced Hydraulic Cutting: Clean, Safe & Automated

Our hydraulic cutting system delivers a cleaner, safer, and more efficient alternative to traditional methods. The process generates no fine dust, keeping your workspace clean and making material collection straightforward.

Built for Reliability & Easy Maintenance

The machine integrates a hydraulic cutting system, a secure clamping unit, and an automatic material pushing mechanism into a compact structure. It is engineered for reliable performance and is designed for easy maintenance. We ensure quality from the inside out, using Taiwan-made hydraulic components and Schneider electrical switches from France.

Key Benefits of Automation

1. Enhanced Safety

The automatic feeding system eliminates the need for operators to approach the cutting area. A programmed action sequence (like clamp-then-cut) prevents accidents caused by human error, ensuring completely safe operation.

2. Guaranteed Precision & Consistency

Preset the cutting length, and the system does the rest. The program controls the feeding cylinder with precision, ensuring every piece is identical. The synchronized clamping prevents material slippage, guaranteeing a clean, straight cut every time and improving cutting accuracy.

3. Boosted Production Efficiency

Automation streamlines the entire process. The system handles feeding, stopping, and resetting without manual intervention, dramatically increasing cutting speed and overall productivity.

4. Reduced Labor & Costs

Operators simply load the raw material and set the parameters. This significantly lowers labor costs and reduces physical strain, making it ideal for long-term, high-volume production.

5. Minimized Material Waste

Precise control over the feed length prevents errors, minimizing material waste. Cut pieces drop neatly into a collection box, and the self-cleaning work area ensures consistent accuracy batch after batch.

| Model number | CDO-PT35 | CDO-PT60 | CDO-PT85 |

| Voltage | 380V, 3 Phase, 50Hz | ||

| Applicable materials | Silver, Gold, Copper, Zinc, Tin, Lead etc | ||

| Hydraulic station power | 5.5KW | 7.5KW | 11Kw |

| Rated shear force | 35ton | 60ton | 85Ton |

| Max size limit for input material (Customizable) | 550*105*30mm (L*W*T) | 650*140*50mm (L*W*T) | 750*165*130mm (L*W*T) |

| External dimensions | 800×700×1310mm | 1200×800×1500mm | 1600×1400×1770mm |

| Weight | 700 kg | 1100kg | 1400kg |

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Hydraulic Shearing Machine

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….