- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the Most advanced Hydraulic Logo Stamping Machine For Types Of Metals Bar

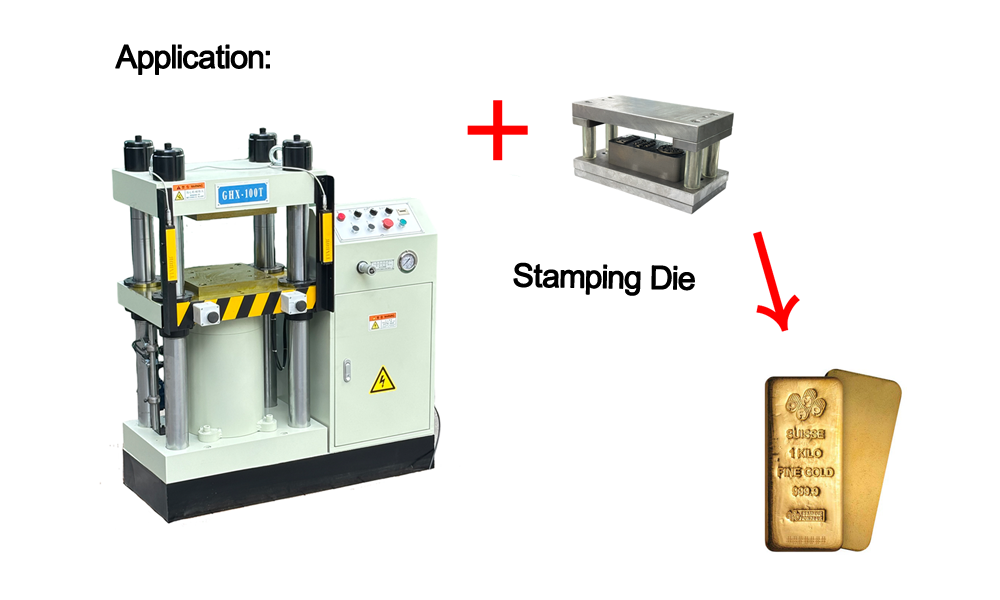

CDOCAST’s compact four-column hydraulic press is engineered for the precious metals industry. Designed for stamping marks and logos onto gold bars, silver bars, platinum ingots, and more, this machine guarantees flawless branding that enhances product value and strengthens your brand identity. It is the ideal stamping solution for both small workshops and large-scale precious metal processing plants.

High-Precision Pressure Control

Achieve perfectly consistent marks on precious metals of any hardness. Our advanced pressure regulation system allows for precise adjustments in increments as fine as 0.1 tons, ensuring every impression is sharp and clear.

Long-Lasting Alloy Molds

Each press comes standard with high-hardness alloy steel molds. Through specialized heat treatment and surface hardening processes, our dies are built for endurance, standing up to high-frequency use without compromising on stamp quality.

Quick-Die-Change System

Maximize your productivity with our tool-free, modular die installation. Changeover time is reduced to under one minute, allowing for flexible switching between multiple dies to meet diverse production demands.

Adjustable Stamping Speed

Tailor the machine’s cycling speed to your output requirements. This adjustable feature provides the flexibility to prioritize either high-volume production or meticulous, deliberate stamping, making it a versatile asset for any production schedule.

Intelligent Safety Protection

Operate with complete peace of mind. The press is equipped with an automatic overload protection system, two-hand operation buttons, and an emergency stop switch, ensuring a secure working environment.

Energy Efficient & Low Noise

Our high-efficiency motor reduces energy consumption by up to 20%. Combined with a remarkably quiet operation of under 75 dB, this press is as environmentally friendly as it is cost-effective.

Please click here to watch video

| Model | Unit | CDO-100S1 | CDO-200S1 | CDO-300S1 | |

| Rated capacity | Ton | 100 | 200 | 300 | |

| Max.System pressure | Mpa | 63 | 63 | 63 | |

| Stroke of movable working table | mm | 100 | 100 | 100 | |

| Opening height | mm | 190 | 250 | 300 | |

| Height of working platform from ground | mm | 890 | 1050 | 1020 | |

| Upward speed of movabale working table | mm/s | 5 | 5 | 5 | |

| Returning speed of movabale working table | mm/s | 2 | 3 | 5 | |

| Movable working table size | L-R between column | mm/s | 220 | 230 | 250 |

| F-B Rim | mm/s | 220 | 230 | 160 | |

| Overall dimension | L-R | mm | 500 | 520 | 580 |

| F-B | mm | 500 | 520 | 860 | |

| H | mm | 1200 | 1470 | 1500 | |

| Motor power | KW | 0.75 | 1.5 | 3 | |

| Weight (Approx.) | Kgs | 320 | 460 | 820 | |

Purpose-Built for Gold: Designed specifically for stamping characters and logos onto gold bars, ensuring clean and permanent marks.

Simple & Space-Saving: Features a simple structure and compact design, making it an easy-to-operate and space-efficient solution for any workshop.

Affordable Power: A highly cost-effective press that delivers immense value, generating tens of tons of pressure for high-quality results.

Ideal for Small Batch Production: Perfectly suited for small studios and factories looking for a reliable, low-maintenance stamping solution.

Streamlined Operation: The process is simplified and typically requires no additional pad formwork, getting you from setup to production in no time.

The stamping capacity depends primarily on the surface area (cross-section) and the thickness of the metal bar. In standard production, this model is fully capable of hallmarking casting bars up to 12.5kg (400 oz standard gold delivery bars) and smaller.

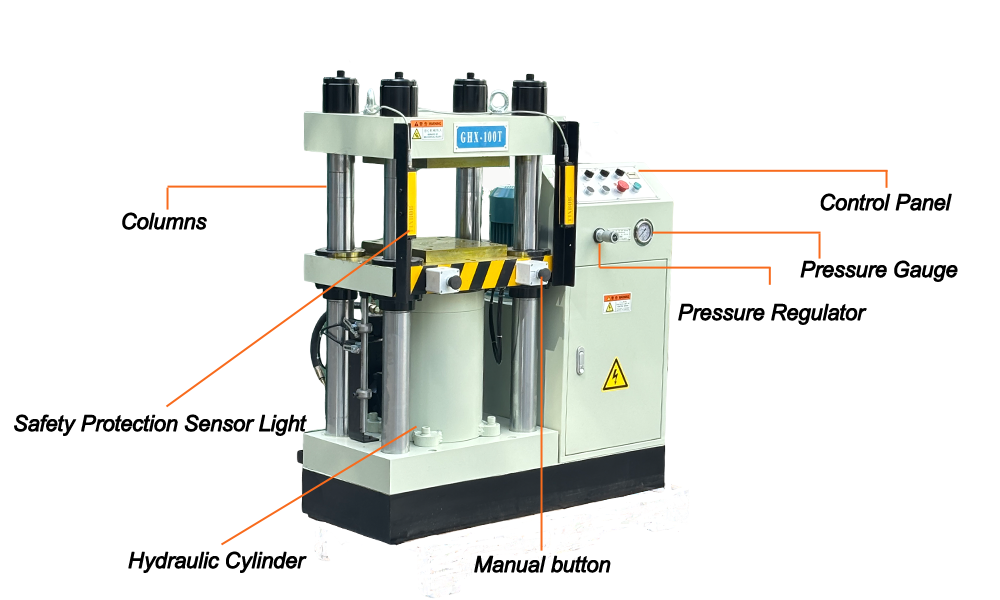

Easy Operation: A pressure control valve is located on the front of the machine, allowing you to flexibly adjust the force based on the bar size and the required depth of the stamp.

Real-time Monitoring: A pressure gauge on the right side allows operators to monitor the exact tonnage during the process, ensuring consistent stamping quality across every batch.

Yes, we offer complete custom tooling solutions.

Precision Alignment: We customize branding dies (stamping dies) based on your specific casting bar dimensions.

Integrated Die Sets: Our dies feature an integrated frame design with built-in positioning. Operators simply place the bar into the fixture for perfect alignment, and the bar can be removed smoothly after pressing, significantly increasing production efficiency.

We do not recommend this specific model for high-relief “minted” products (Minting Bars & Coins) for the following reasons:

Pressure Precision: Minting requires extreme precision for intricate relief; this stamping machine is optimized for hallmarking and logo identification.

Action Logic: Minting requires a “Fast Down — Slow Pressing — Slow Return” cycle to ensure full metal flow into fine details.

Speed vs. Aesthetics: This machine is designed with a “FastUp/Fast Down” logic to maximize stamping speed. While excellent for logos, it may not meet the aesthetic requirements of proof-like minted coins.

For high-quality coin production, please inquire about our Hydraulic Minting Press series

This machine is specifically engineered for precious metals, including Gold, Silver, Platinum, and Palladium bars of varying hardness.

Absolutely. By using interchangeable die inserts, you can simultaneously stamp your brand logo, weight (e.g., 1kg), purity (e.g., 999.9), and unique serial numbers

Our die features a “Quick-Change Tooling” design. No complex tools are required; a single operator can complete a die change in under 30 seconds, making it ideal for small-batch production of various bar sizes.

The dies are made from high-hardness alloy steel and undergo specialized heat treatment. Under normal operating conditions, a single set of dies can perform tens of thousands of stampings while maintaining sharp edges.

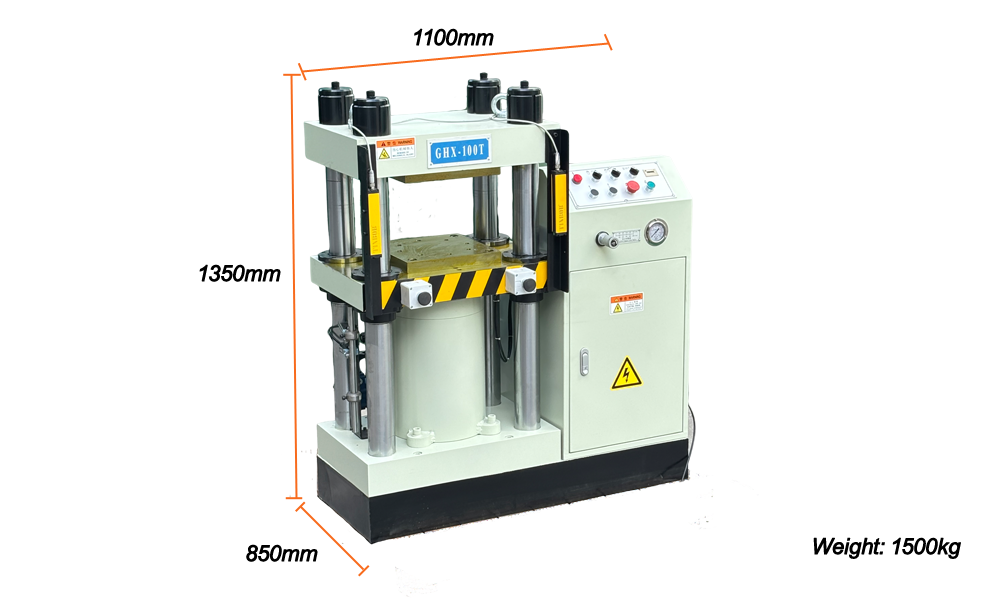

The hydraulic system is optimized to operate at under 75 decibels. Its compact footprint 110 *85 *135cm makes it perfect for small-to-medium factories or urban jewelry workshops.

We have implemented a four-tier safety protection system to ensure operator security:

Light Curtains: High-sensitivity infrared sensors stop the machine instantly if a foreign object enters the stamping zone.

Dual Start Logic: In semi-automatic mode, the operator must press two buttons simultaneously with both hands to prevent injury.

Flexible Controls: Choose between manual or semi-automatic modes, with the option for dual-button or foot-pedal control.

Emergency Stop: A prominent red E-Stop button provides millisecond-level power cutoff in emergencies.

The machine uses an energy-efficient 4KW motor, which saves approximately 20% more energy compared to traditional hydraulic presses. We offer custom configurations for both single-phase and three-phase power.

Warranty: CDOCAST provides a 2-year quality guarantee, including free replacement of non-wear parts.

Setup: No complex installation is required. The machine is fully calibrated before shipping; you only need to connect the power and add anti-wear hydraulic oil to begin. We provide detailed operation videos and manuals

No complex installation is required. The machine is fully commissioned and tested before leaving the factory; you only need to connect the power supply and add anti-wear hydraulic oil to begin operations. We provide comprehensive instructional videos and operation manuals to guide you.

The four-column design is the preferred choice for stamping gold and silver bars due to its superior stability, ensuring the die maintains a perfectly vertical press without deviation. To maintain high-precision performance over time, we recommend the following maintenance routine:

Guide Pillar Lubrication: Regularly apply lubricant to the four chrome-plated guide pillars to minimize friction and prevent corrosion.

Safety System Inspection: Regularly test the sensitivity of the light curtain guards and the emergency stop button to ensure the four-tier safety protection system is functioning at its best.

The stamping capacity depends primarily on the surface area (cross-section) and the thickness of the metal bar. In standard production, this model is fully capable of hallmarking casting bars up to 12.5kg (400 oz standard gold delivery bars) and smaller

Yes, the machine supports precision pressure adjustment.

(1) Easy Operation: A pressure control valve is located on the front of the machine, allowing you to flexibly adjust the force based on the bar size and the required depth of the stamp.

(2) Real-time Monitoring: A pressure gauge on the right side allows operators to monitor the exact tonnage during the process, ensuring consistent stamping quality across every batch.

Yes, we offer complete custom tooling solutions.

(1) Precision Alignment: We customize branding dies (stamping dies) based on your specific casting bar dimensions.

(2) Integrated Die Sets: Our dies feature an integrated frame design with built-in positioning. Operators simply place the bar into the fixture for perfect alignment, and the bar can be removed smoothly after pressing, significantly increasing production efficiency.

We do not recommend this specific model for high-relief "minted" products (Minting Bars & Coins) for the following reasons:

(1) Pressure Precision: Minting requires extreme precision for intricate relief; this stamping machine is optimized for hallmarking and logo identification.

(2)Action Logic: Minting requires a "Fast Down — Slow Pressing — Slow Return" cycle to ensure full metal flow into fine details.

(3)Speed vs. Aesthetics: This machine is designed with a "Fast Up/Fast Down" logic to maximize stamping speed. While excellent for logos, it may not meet the aesthetic requirements of proof-like minted coins.

For high-quality coin production, please inquire about our Hydraulic Minting Press series

This machine is specifically engineered for precious metals, including Gold, Silver, Platinum, and Palladium bars of varying hardness.

Absolutely. By using interchangeable die inserts, you can simultaneously stamp your brand logo, weight (e.g., 1kg), purity (e.g., 999.9), and unique serial numbers

Our machine features a "Quick-Change Tooling" design. No complex tools are required; a single operator can complete a die change in under 30 seconds, making it ideal for small-batch production of various bar sizes.

The dies are made from high-hardness alloy steel and undergo specialized heat treatment. Under normal operating conditions, a single set of dies can perform tens of thousands of stampings while maintaining sharp edges.

The hydraulic system is optimised to operate at under 75 decibels24. Its compact footprint, 110 *85 *135 cm, makes it perfect for small-to-medium factories or urban jewelry workshops。

We have implemented a four-tier safety protection system to ensure operator security:

(1)Light Curtains: High-sensitivity infrared sensors stop the machine instantly if a foreign object enters the stamping zone.

(2)Dual Start Logic: In semi-automatic mode, the operator must press two buttons simultaneously with both hands to prevent injury.

(3)Flexible Controls: Choose between manual or semi-automatic modes, with the option for dual-button or foot-pedal control.

(4)Emergency Stop: A prominent red E-Stop button provides millisecond-level power cutoff in emergencies

The machine uses an energy-efficient 4KW motor, which saves approximately 20% more energy compared to traditional hydraulic presses. We offer custom configurations for both single-phase and three-phase power.

(1) Warranty: CDOCAST provides a 2-year quality guarantee, including free replacement of non-wear parts.

(2) Setup: No complex installation is required. The machine is fully calibrated before shipping; you only need to connect the power and add anti-wear hydraulic oil to begin. We provide detailed operation videos and manuals.

No complex installation is required. The machine is fully commissioned and tested before leaving the factory; you only need to connect the power supply and add anti-wear hydraulic oil to begin operations. We provide comprehensive instructional videos and operation manuals to guide you.

The four-column design is the preferred choice for stamping gold and silver bars due to its superior stability, ensuring the die maintains a perfectly vertical press without deviation. To maintain high-precision performance over time, we recommend the following maintenance routine:

(1)Guide Pillar Lubrication: Regularly apply lubricant to the four chrome-plated guide pillars to minimise friction and prevent corrosion.

(2) Hydraulic Oil Management: Periodically check the hydraulic oil levels and ensure the fluid remains clean according to the operation manual.

(3) Safety System Inspection: Regularly test the sensitivity of the light curtain guards and the emergency stop button to ensure the four-tier safety protection system is functioning at its best.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

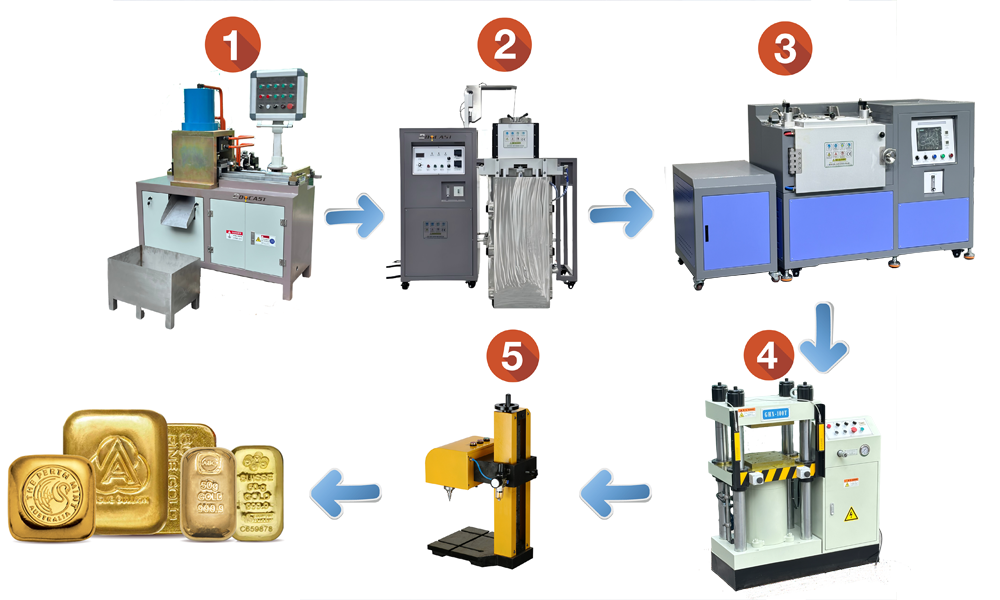

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Hydraulic Logo Stamping Machine

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….