- Call Us: 008615168765707

- Mail Us: [email protected]

CDOCAST Professional Hollow Tube Forming Machine for Gold Silver Copper

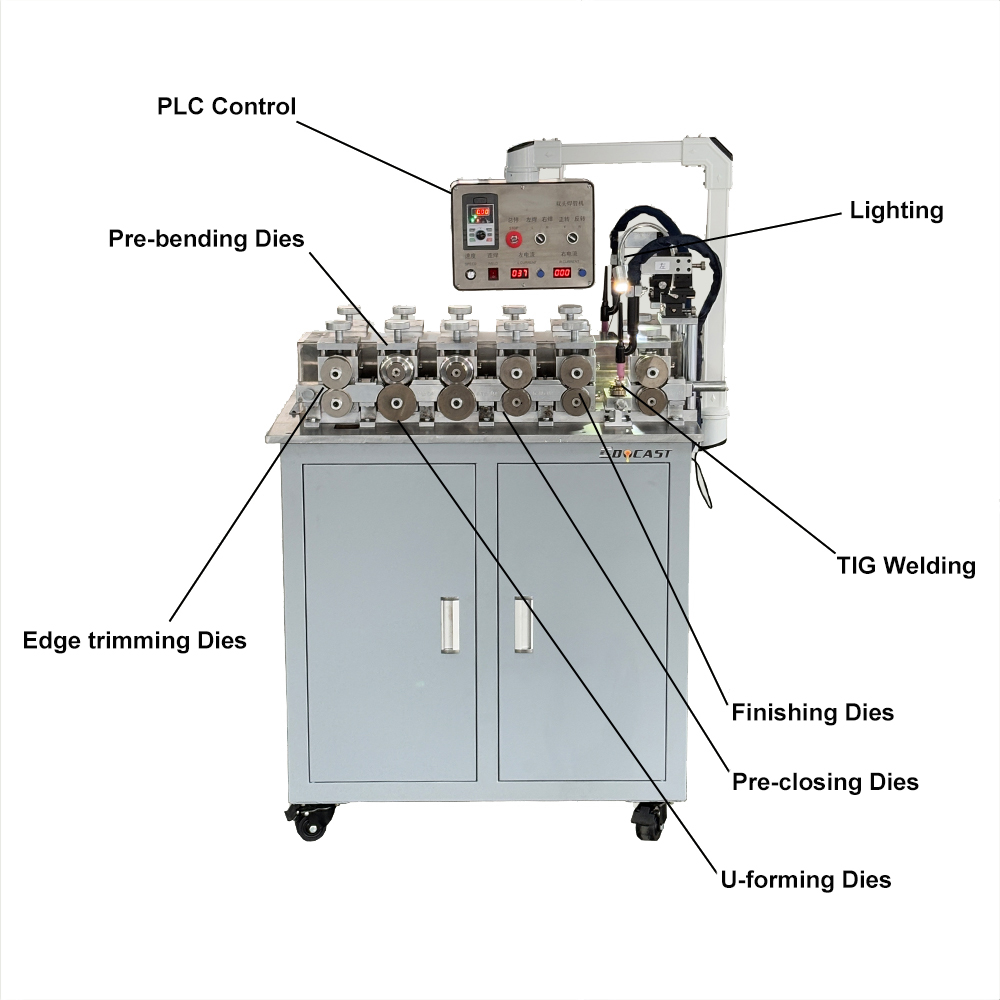

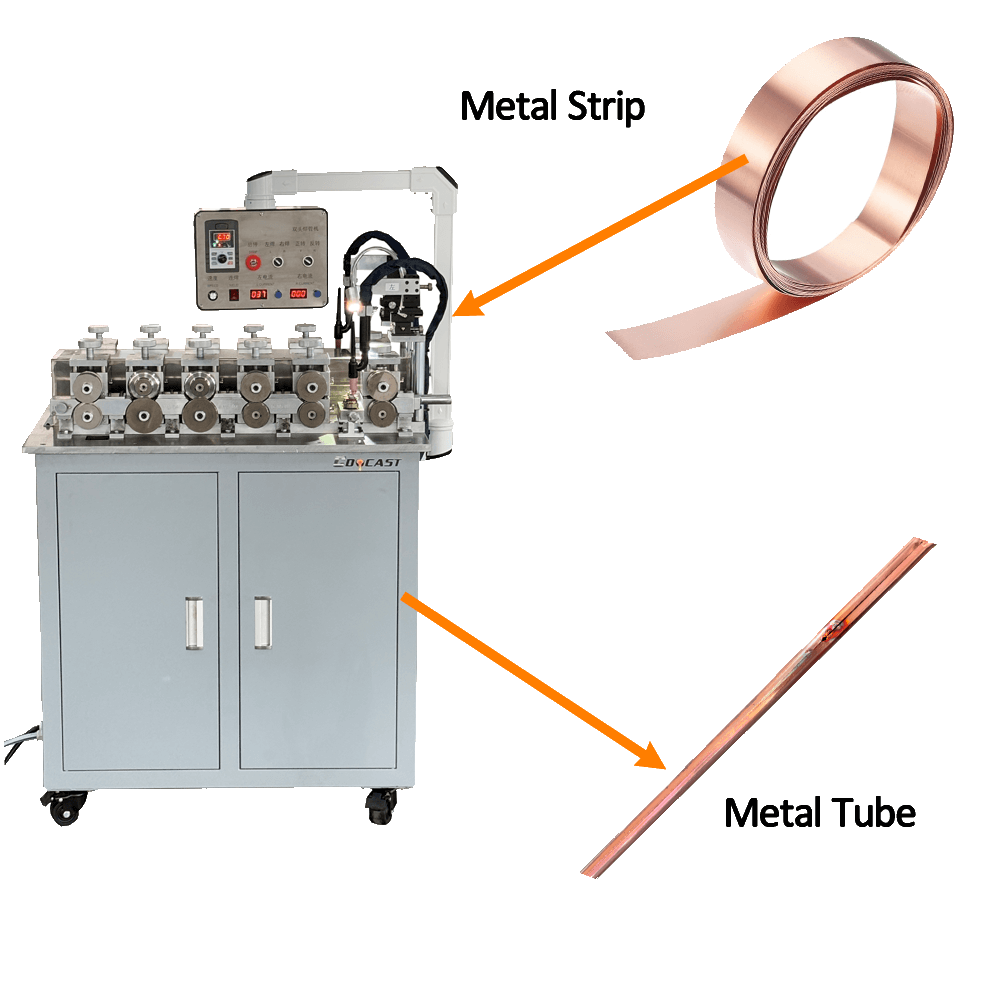

CDOCAST Hollow tube forming machine is an advanced automatic solution designed for producing high-quality metal hollow tubes from strips, supporting various diameters and thicknesses. It is compatible with soft metals such as gold, K gold, silver, and copper, and features an integrated argon welding system for seamless forming and welding. The innovative double-line design enables the simultaneous production of tubes in two different diameters, streamlining subsequent processing. With motorized variable speed control, this machine is ideal for jewelry manufacturing and other precision metalworking applications.

Our Hollow tube forming machine is designed to enable you to simply and effectively produce tubes of various shapes and sizes. Utilizing continuous roll forming combined with high-frequency welding technology, it processes metal strips such as gold, silver, and copper into precision hollow tubes. It achieves one-stop production from coil material to finished tubes, making it particularly well-suited for high-end applications like precious metal thin-walled tubes and capillary tubes.

One key advantage of the hollow tube forming machine is that it enhances productivity and reduces costs. It can manufacture numerous metal tubes much faster than older methods. Furthermore, the machine provides a high degree of precision and accuracy, ensuring each tube produced meets the necessary standards. By efficiently cutting and forming the metal, the machine maximizes the utilization of raw materials. This minimizes waste and reduces expenses.

| Model | CDO-TF01 | CDO-TF02 |

| Voltage | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz |

| Motor Power | 1.5KW | 1.5KW |

| Tube Die Size | Ф4-11.5mm | Ф4-11.5mm |

| Tube Die Amount | Customized 1 Set | Customized 2 Set |

| Tube Die Hardness | HRC 52 | HRC 52 |

| Die Speed | 17r/min | 17r/min |

| Argon Welder | 220V-200A-1 Set | 220V-200A-2 Set |

| Size | 1230x510x1160mm | 1500x746x1650mm |

| Weight | 400kg | 600kg |

1. CDOCAST Hollow tube forming machine can process metal strips such as gold, silver, and copper, and the output diameter can be customized. Specially suitable for high-end manufacturing fields such as jewelry precision capillary tubes, building decoration tubes, and HVAC system tubes.

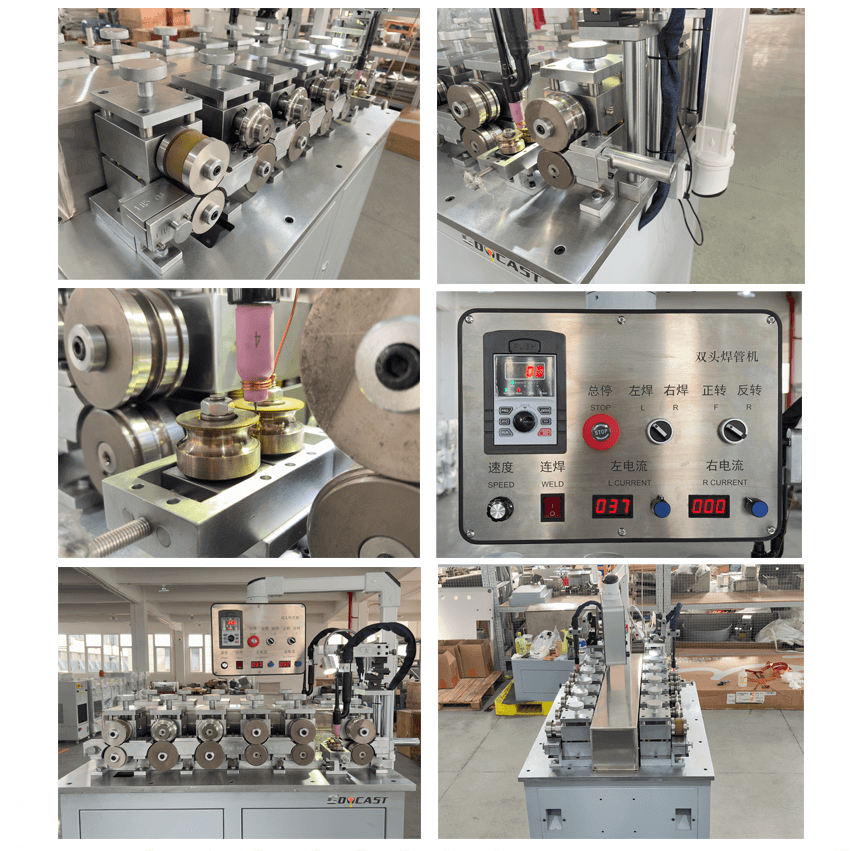

2. Integrating four core modules: continuous roll forming, high-frequency welding (10-100kHz), online sizing, and chip-free cutting, a single machine completes the complete process from coil to finished pipe.

3. Revolutionary production efficiency and precision, with production speed reaching 350% of traditional equipment and material utilization rate exceeding 99.3%.

4. The weld strength reaches 98% of the base material (argon gas shielded welding), which can achieve perfect seamless welding.

5. By efficiently cutting and forming metals, CDOCAST hollow tube forming machine can maximize the use of raw materials, minimize waste, and minimize costs.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Hollow Tube Forming Machine

Contact Our Engineer Team

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….