- Call Us: 008615168765707

- Mail Us: [email protected]

Buy The Most Popular Hollow Ball Making Machine In The Market

CDOCAST Hollow Ball Making Machine is suitable for making different shapes & sizes and materials of hollow balls, such as gold, karat gold, silver, and copper, etc.

In the realm of precision and efficiency-driven metal processing, CDOCAST Hollow Bead Making Machine is your ideal solution for the batch production of high-quality hollow metal spheres. Specifically designed to meet the demands of the jewelry manufacturing, hardware components, decorative items, and other precision metal processing industries, it rapidly and accurately transforms hollow tubes into hollow balls with diverse geometries and uniform dimensions.

Hollow ball making machine adopts advanced automated design, simplifying the complex ball making process into efficient and smooth automatic operations:

1. Feeding: The Metal tube is precisely fed into the processing area.

2. Precision Stamping: The tube is stamped using precision dies to form the basic contour of the sphere.

3. Automatic Folding & Forming: In this critical stage, the equipment automatically performs precision folding and closure of the stamped metal, forming a seamless hollow structure.

| Model | CDO-HBM1 | CDO-HBM2 |

| Voltage | 380V, 3 Phase, 50Hz | 380V, 3 Phase, 50Hz |

| Motor Power | 3KW | 3KW |

| Bead Diameter | Ф2-6mm | Ф6-10mm |

| Bead Making Speed | 3400 Beads/Hour | 3400 Beads/Hour |

| Size | 650x600x1230mm | 650x600x1230mm |

| Weight | 600kg | 600kg |

Hollow Ball Making Machine Feature:

1. Wide material applicability: CDOCAST hollow ball making machine can efficiently process various commonly used metal sheets such as gold (pure gold, K gold), silver, copper, etc.

2. Diversified sphere production: Easily manufacture hollow spheres in various shapes, including standard spheres (round spheres), rugby balls (oval spheres), teardrop spheres, abacus beads, and other customized-shaped balls.

3. Precision size range: Hollow ball making machine can stably produce hollow balls with diameters ranging from 2mm to 10mm, meeting the precise requirements of different application scenarios.

4. Industry applications: Widely used in jewelry (such as bead chains, pendants, decorative elements), hardware accessories (such as handles, decorative buckles), handicrafts, clothing accessories and other fields.

5. Easy and efficient operation: With automated process design, operators mainly undertake simple tasks such as loading, monitoring, and receiving materials. The learning curve is short, saving the cost of hiring physical labor.

6. Stable, reliable and durable: The sturdy mechanical structure and high-quality core components ensure the stability and durability of the equipment under long-term continuous operation.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Hollow Ball Making Machine

Contact Our Engineer Team

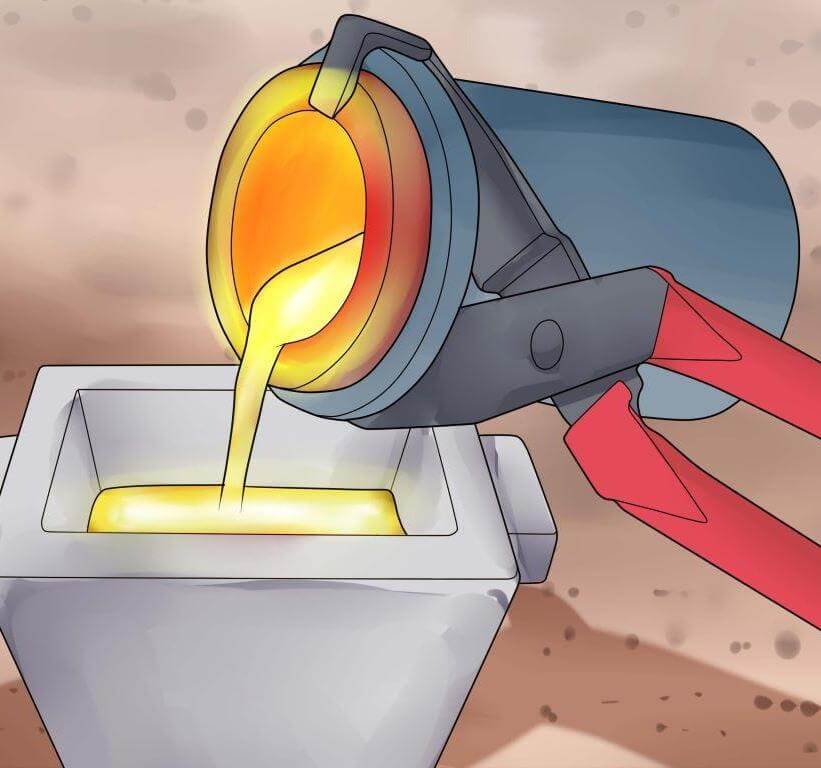

This pricing guide helps to give you an idea about the initial budget and the ownership costs associated with each type of gold melting furnaces.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

CDOCAST Gold melting furnace is absolutely inventive design furnaces which is designed with the aim of offering effective melting action on precious metals……

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….