- Call Us: 008615168765707

- Mail Us: [email protected]

The most popular Gold Bar and Coin Blister Packaging Machine for sale. Inquiry now!

CDOCAST Gold Silver Bar and Coin Blister Packaging Machine is a specialized automated system designed to securely package gold bars, coins, or other precious metal products in blister packs (clear plastic cavities sealed with a backing material). This type of packaging ensures product visibility, tamper evidence, and protection against environmental factors like oxidation or physical damage. Its innovative rotary table design enables continuous operation, significantly improving productivity in packaging applications.

We specialize in bespoke blister packaging tailored to your needs—incorporate your logo, unique designs, and branding elements seamlessly. Our advanced solutions also offer anti-counterfeiting technologies to ensure product authenticity and security.

Loading – Gold bars/coins are placed into plastic blister cavities (manually or via feeder).

Sealing – HF heating bonds the blister to a backing card/foil.

Cutting – Excess plastic is trimmed (if using sheet-fed designs).

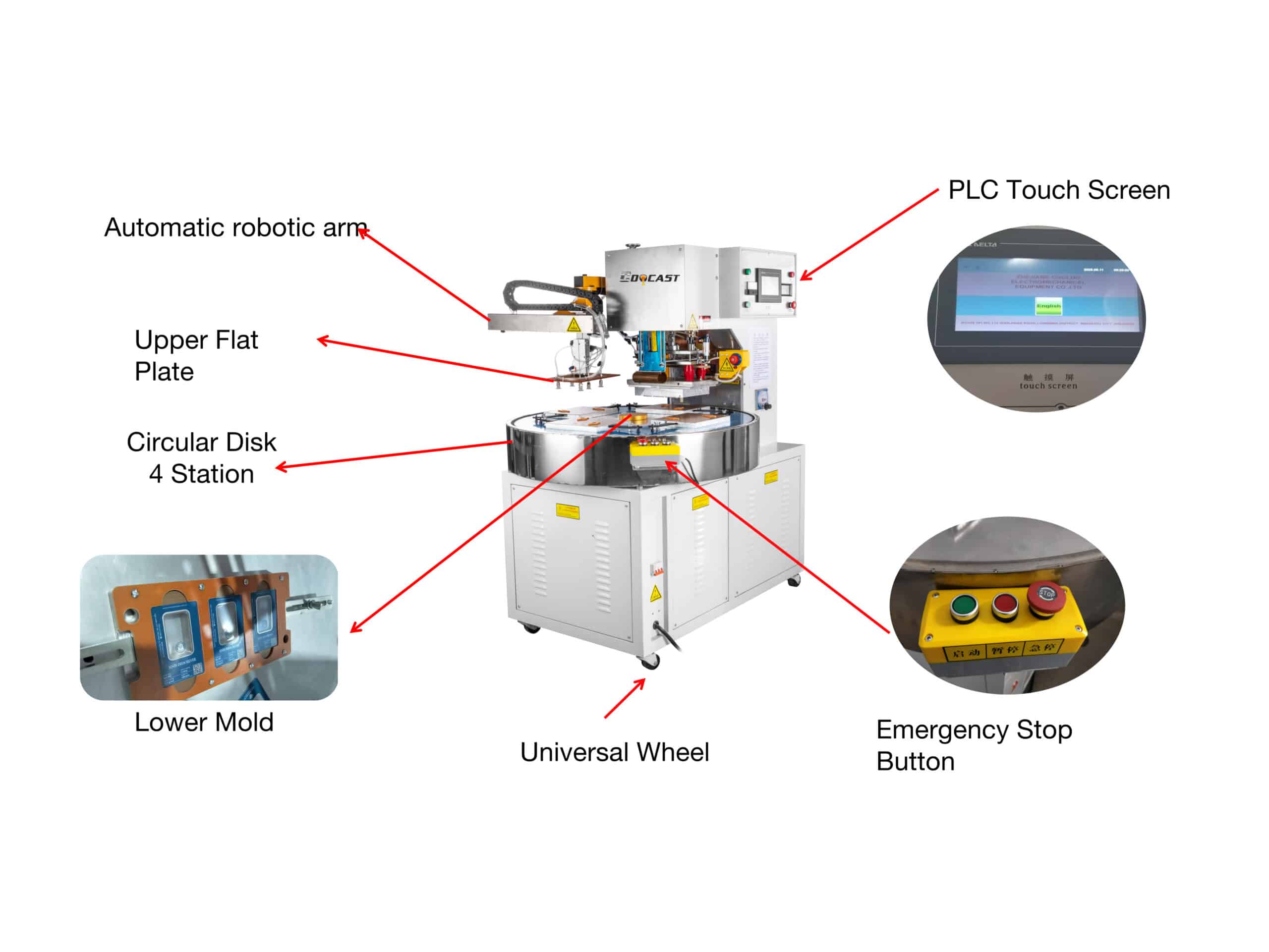

Output – Finished packs are collect by automatic robotic arm.

Advantages Over Traditional Packaging

✔ Enhanced Security – Tamper-evident seals deter theft/fraud.

✔ Product Display – Clear plastic showcases gold while protecting it.

✔ Durability – Resists humidity, scratches, and UV exposure.

✔ Branding Potential – Custom-printed backing cards for logos/certifications.

Video link for 2-station model:https://www.cdocast.com/induction_video/2-station-blister-packaging-machine-for-bars-and-coins/

Video link for 4-station model:https://www.cdocast.com/induction_video/4-station-blister-packaging-machine/

The right packaging sets your coin & bar perfectly in scene.

Beyond blister packaging by Gold Silver Bar and Coin Blister Packaging Machine, we offer a wide variety of different packaging options for your custom-minted coins and bars. Whatever your coin and bar design idea, budget and personal wishes, we will help you and find the perfect solution. Feel free to choose the coin packaging that suits your project: Just an acrylic cup that will protect your coin from external factors or the velvet box, which is available in many colors and can be enhanced by printing your logo.

For more details of Gold Silver Bar and Coin Blister Packaging Machine, welcome to ask us for the best option that suits your project.

Details

Customized Blister Packaging

| Model | CDO-HS5000 | CDO-HS8000 | CDO-MY5000 | CDO-MY8000 |

| Voltage | Three phase 380V±10%, 50/60Hz | |||

| Power | 5 kw | 8 kw | 5 kw | 8 kw |

| Control system | Manual | Manual | Auto(with robotic arm) | Auto(with robotic arm) |

| Oscillating frequency | 27.12MHz | 27.12MHz | 27.12MHz | 27.12MHz |

| Upper and lowver electrode | 200mm | 200mm | 200mm | 200mm |

| Upper platen size | 350*200mm | 400*300mm | 350*200mm | 350*200mm |

| Station | 2 Station | 2 Station | 4 Station | 4 Station |

| Capacity | 800pcs/h | 1000pcs/h | 2000pcs/h | 2200pcs/h |

| Disk size | 600*1000mm | 650*1000mm | φ1000mm | φ1000mm |

| Weight | 250kg | 300kg | 500kg | 570kg |

| Dimension | 1000*650*1750mm | 1000*760*1850mm | 1600*1150*1790mm | 1600*1250*1890mm |

1.High Safety Protection

Equipped with a high-sensitivity 5557 spark prevention system, protecting both the high-frequency (HF) mold and the packaged products.

2.Fully Automatic Operation

Rotary table design allows for continuous production, improving efficiency.

Single-person operation reduces labor costs.

3.User-Friendly & Easy to Learn

PLC + HMI touchscreen interface for easy parameter adjustment. Preset parameter backup function saves setup time.

4.Flexible Production Modes

Single-cycle or continuous mode can be selected based on worker speed.

5.Troubleshooting & Maintenance Convenience

Fault detection system helps quickly identify issues.

Stores previous operation records, simplifying readjustments.

6.High Precision & Consistency

Ensures uniform blister sealing for high-value products like gold coins/bars.

7.Energy Efficient

Optimized HF (high-frequency) technology reduces power consumption.

8.Durable & Long-Lasting

Robust construction with high-quality materials, minimizing wear.

9.Customizable Packaging

Adjustable settings and design for different coin/bar sizes and blister materials.

10.Fast Production Speed

High-speed automation increases output per hour, ideal for large batches.

11.Compliance with Industry Standards

Suitable for banking, minting, and precious metal industries, ensuring secure packaging.

The primary differences lie in the level of automation, production speed, and price.

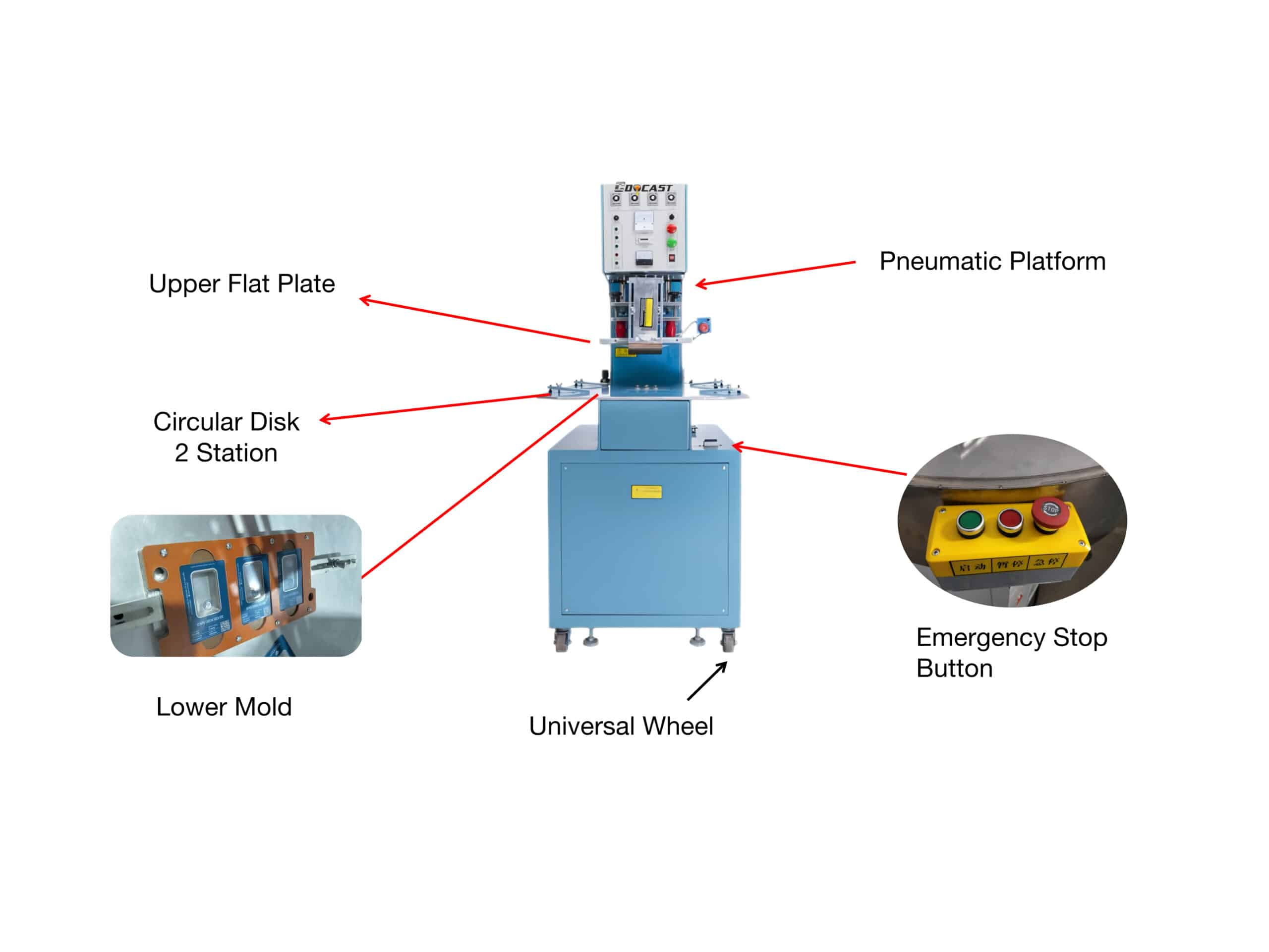

① 2-Station Machine: This model features a simple, cost-effective rotating square turntable with two stations spaced 180 degrees apart. It is user-friendly with a production output of approximately 1000 pieces per hour. It offers excellent value for clients with a single product size and moderate batch sizes who are transitioning from manual to automated packaging.

② 4-Station Machine: This advanced model uses a 1-meter diameter circular turntable with four stations (90 degrees apart). Its key advantage is the integrated robotic arm that automatically removes finished packages, achieving a higher degree of automation. Production efficiency is about 50% higher than the 2-station model, reaching roughly 2,200 pieces per hour. It features a smart PLC and touchscreen control system that stores multiple parameter sets (e.g., 10 groups) for quick changeovers between different products. With automatic fault diagnosis and alerts, it significantly reduces downtime. The 4-station machine is the ideal choice for high-volume production or manufacturers with a wide variety of product types due to its superior flexibility and speed.

Yes, we are a professional manufacturer of custom blister cards for precious metals. Our cards are engineered for aesthetics, security, and functionality.

*Core Material: We primarily use high-quality PET material, known for its excellent toughness, strength, glossy surface, and eco-friendly, non-toxic properties.Full *Customization: We tailor the card’s artwork, layout, and size to match your brand identity perfectly.

*Integrated Features: Enhance your packaging with a range of integrated elements:

✔ Company Information & Brand Logo

✔ QR Codes (linking to official websites, anti-counterfeiting verification)

✔ Product Barcodes (for inventory and sales management)

✔ NFC Chips (enabling advanced anti-counterfeiting, traceability, and interactive experiences)

✔ Physical Anti-Tamper Features (e.g., destructible void designs)

✔ Wide Applicability: Our blister cards are suitable for various precious metal products, including gold bars, silver coins, earrings, necklaces, and more, providing a secure and premium presentation.

Yes, custom molds are required for our blister packaging process. There are two main types:

① Blister Mold (Aluminum Mold): This is mounted on the machine and must be precision-engineered to match the exact dimensions of each specific gold/silver bar or coin. Therefore, each unique product size requires its own dedicated aluminum mold.

② Card Die-Cutting Mold (Steel Rule Die): This is used to punch the printed card into its final shape. Typically, one card size requires one die.

Cost-Saving Tip: Multi-Cavity Molds. To help reduce your initial mold investment, we offer mold combination services. You can combine 2 or 4 different product card designs into a single die-cutting mold. Subsequent orders for these combined products must be produced in equal quantities. Our team can advise on which sizes can be efficiently combined based on your needs.

Our machines use a reliable and precise method for secure sealing.

*Operation Process:

2-Station: An operator manually rotates the turntable to position the mold under the sealing head. A sensor triggers the automatic descent of the head for pressing. Meanwhile, the operator can load the next product at the opposite station. Once sealing is complete, the head retracts, and the operator rotates the turntable to remove the finished package.

4-Station: The process is similar but more automated. After sealing, a robotic arm automatically picks and places the finished package onto a conveyor or collection tray, significantly boosting efficiency.

*Working Principle: The machine utilizes High-Frequency (HF) energy to create an instant, penetrating heat seal. This method ensures a strong, permanent bond without burning or damaging the delicate surface of your precious metal products. It employs a direct pneumatic pressing system for uniform pressure distribution across the entire seal area. The system is equipped with an anti-arcing (spark suppression) protection circuit, which safeguards both the expensive HF molds and your valuable products.

We do not offer free samples for custom-designed blister cards. Each custom design requires the creation of unique printing plates and setup, which incurs specific production costs. However, we are pleased to provide a free Standard Sample Kit at no charge. This kit contains physical samples of various standard materials and printing techniques, allowing you to evaluate our print quality, material feel, and functional capabilities to inform your design process.

The suitability for blister packaging is primarily determined by a product’s physical dimensions (Length, Width, Thickness) rather than its weight alone. As long as the product’s size can be accommodated within the machine’s mold and platen area, it can be packaged. Even items with a high gram weight are perfectly suitable if their physical dimensions fall within the machine’s design limits. Our solutions are versatile and can be adapted for a wide range of precious metal items, from large bars to delicate coins and jewelry like earrings and necklaces.

The primary differences lie in the level of automation, production speed, and price. ① 2-Station Machine: This model features a simple, cost-effective rotating square turntable with two stations spaced 180 degrees apart. It is user-friendly with a production output of approximately 1000 pieces per hour. It offers excellent value for clients with a single product size and moderate batch sizes who are transitioning from manual to automated packaging. ② 4-Station Machine: This advanced model uses a 1-meter diameter circular turntable with four stations (90 degrees apart). Its key advantage is the integrated robotic arm that automatically removes finished packages, achieving a higher degree of automation. Production efficiency is about 50% higher than the 2-station model, reaching roughly 2,200 pieces per hour. It features a smart PLC and touchscreen control system that stores multiple parameter sets (e.g., 10 groups) for quick changeovers between different products. With automatic fault diagnosis and alerts, it significantly reduces downtime. The 4-station machine is the ideal choice for high-volume production or manufacturers with a wide variety of product types due to its superior flexibility and speed.

Yes, we are a professional manufacturer of custom blister cards for precious metals. Our cards are engineered for aesthetics, security, and functionality.

*Core Material: We primarily use high-quality PET material, known for its excellent toughness, strength, glossy surface, and eco-friendly, non-toxic properties.Full *Customization: We tailor the card’s artwork, layout, and size to match your brand identity perfectly.

*Integrated Features: Enhance your packaging with a range of integrated elements:

✔ Company Information & Brand Logo

✔ QR Codes (linking to official websites, anti-counterfeiting verification)

✔ Product Barcodes (for inventory and sales management)

✔ NFC Chips (enabling advanced anti-counterfeiting, traceability, and interactive experiences)

✔ Physical Anti-Tamper Features (e.g., destructible void designs)

✔ Wide Applicability: Our blister cards are suitable for various precious metal products, including gold bars, silver coins, earrings, necklaces, and more, providing a secure and premium presentation.

Yes, custom molds are required for our blister packaging process. There are two main types:

① Blister Mold (Aluminum Mold): This is mounted on the machine and must be precision-engineered to match the exact dimensions of each specific gold/silver bar or coin. Therefore, each unique product size requires its own dedicated aluminum mold.

② Card Die-Cutting Mold (Steel Rule Die): This is used to punch the printed card into its final shape. Typically, one card size requires one die.

Cost-Saving Tip: Multi-Cavity Molds. To help reduce your initial mold investment, we offer mold combination services. You can combine 2 or 4 different product card designs into a single die-cutting mold. Subsequent orders for these combined products must be produced in equal quantities. Our team can advise on which sizes can be efficiently combined based on your needs.

Our machines use a reliable and precise method for secure sealing.

*Operation Process:

2-Station: An operator manually rotates the turntable to position the mold under the sealing head. A sensor triggers the automatic descent of the head for pressing. Meanwhile, the operator can load the next product at the opposite station. Once sealing is complete, the head retracts, and the operator rotates the turntable to remove the finished package.

4-Station: The process is similar but more automated. After sealing, a robotic arm automatically picks and places the finished package onto a conveyor or collection tray, significantly boosting efficiency.

*Working Principle: The machine utilizes High-Frequency (HF) energy to create an instant, penetrating heat seal. This method ensures a strong, permanent bond without burning or damaging the delicate surface of your precious metal products. It employs a direct pneumatic pressing system for uniform pressure distribution across the entire seal area. The system is equipped with an anti-arcing (spark suppression) protection circuit, which safeguards both the expensive HF molds and your valuable products.

We do not offer free samples for custom-designed blister cards. Each custom design requires the creation of unique printing plates and setup, which incurs specific production costs. However, we are pleased to provide a free Standard Sample Kit at no charge. This kit contains physical samples of various standard materials and printing techniques, allowing you to evaluate our print quality, material feel, and functional capabilities to inform your design process.

The suitability for blister packaging is primarily determined by a product’s physical dimensions (Length, Width, Thickness) rather than its weight alone. As long as the product’s size can be accommodated within the machine’s mold and platen area, it can be packaged. Even items with a high gram weight are perfectly suitable if their physical dimensions fall within the machine’s design limits. Our solutions are versatile and can be adapted for a wide range of precious metal items, from large bars to delicate coins and jewelry like earrings and necklaces.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Gold Bar and Coin Blister Packaging Machine

Contact Our Engineer Team

How To Purchase A Most Suitable Gold Testing Machine to test the purity of your gold and silver, Click here

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

Gold and silver have long been regarded as safe-haven assets, especially during times of economic uncertainty, political instability, or financial crisis. While traditional investments like stocks, real estate, and mutual funds can be highly volatile, gold and silver tend to retain—or even increase—in value.

Hydraulic Punching Machine operation video,Click here you can learn more about how to use our machine