- Call Us: 008615168765707

- Mail Us: [email protected]

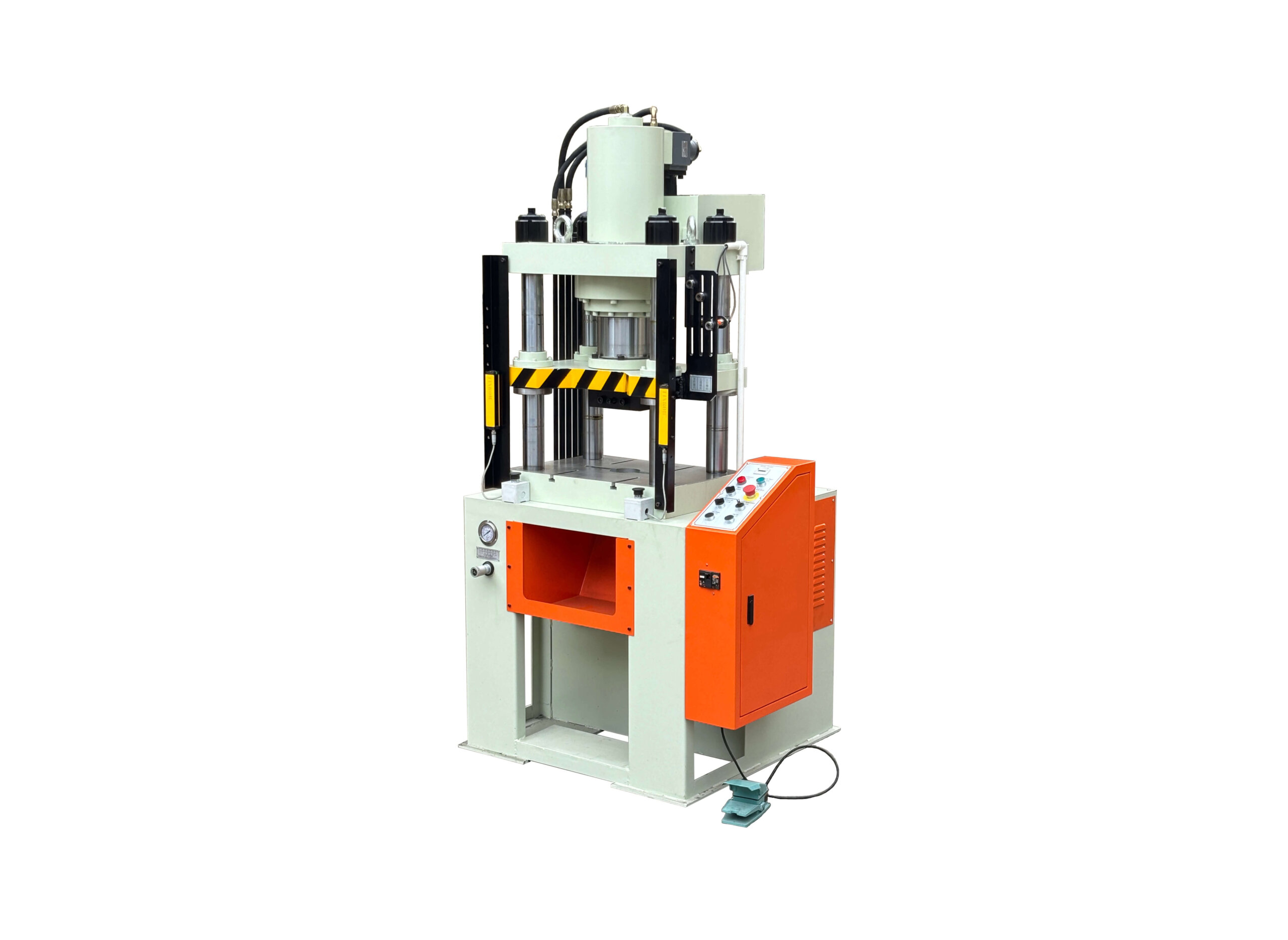

Hydraulic Press For Coin &Bar Minting .Customized Design Available

CDOCAST specializes in manufacturing high-precision hydraulic minting presses designed for creating sharp, detailed designs on gold and silver bars and coins

At the heart of our machine is a powerful hydraulic system. The process begins when a hydraulic pump converts mechanical energy into hydraulic energy. This energy is then transmitted via specialized hydraulic oil to a hydraulic cylinder, which converts it back into controlled mechanical force. This force is applied with high precision to stamp your custom designs onto workpieces, ensuring every detail is captured perfectly.

① Economical Logo Stamping Machine: Ideal for clients who require a simple, cost-effective solution for pressing custom patterns onto gold bars. This model is compact, user-friendly, and perfect for applications where a basic, high-quality stamp is sufficient without the need for an automatic ejector.

② Advanced Hydraulic Coining Press: Necessary for minting high-relief coins and complex bars. This robust press is designed for demanding production environments and can be equipped with automatic features for enhanced efficiency and output quality.

③ Robust Structural Options: Our presses are available in two primary structures to suit your technical requirements:

④ Four-Pillar Hydraulic Press: Offers exceptional stability and alignment under high tonnage, ideal for the most critical minting applications.

⑤ Frame-Type Hydraulic Press: Provides superior rigidity and guiding accuracy, ensuring consistent performance and prolonged die life. Furthermore, they can be configured with the cylinder positioned above or below (C-frame style), providing flexibility for various production line setups.

⑥ Tailored to Your Minting Needs: Each of our hydraulic presses can be equipped with an automatic control panel for simple operation, allowing for easy adjustment of pressure and speed. The required press tonnage is determined by the material thickness, coin size, and design complexity of your pattern. As a complete solution provider, CDOCAST also offers professional custom logo and mold design services to bring your unique vision to life.

We understand that your needs are unique. That’s why we offer a range of solutions:

▶ For straightforward logo stamping, our compact and economical model delivers reliability and value.

▶ For complex coin and bar production, our advanced hydraulic coining presses offer the robustness and control required for high-volume, high-quality output.

▶ With a choice between the superior alignment of our four-pillar presses and the exceptional rigidity of our frame-type models, you can select the perfect foundation for your precision work.

▶ From Concept to Coin

Beyond the machine itself, we partner with you throughout the process. From recommending the ideal tonnage for your specific material and design to providing end-to-end custom mold design and manufacturing, CDOCAST is your single source for a complete minting solution.

• High Efficiency & Power: Hydraulic power transmission provides high energy conversion efficiency, generating significant pressure and force for demanding applications.

• Robust & Simple Design: Featuring a relatively simple structure and a compact design, our hydraulic systems are engineered for reliability and ease of maintenance.

• Precise Control: Operators can easily and accurately adjust both pressure and speed via control valves, ensuring simple operation for different processing needs.

• Smooth Operation: The press maintains a stable working process with minimal vibration, which is critical for achieving high processing accuracy.

• Versatile Applications: This hydraulic press is suited for a wide range of processing techniques, including stamping, forming, cutting, and pressing.

• Built-in Safety: Modern safety features are integrated to guarantee secure and reliable operation at all times.

Click to Learn More About the dies

| Model | Unit | CDO-100M1 | CDO-200M1 | CDO-300E1 | CDO-500M1 | CDO-1000M1 | CDO-1500M1 | CDO-2000M1 | |

| Rated capacity | Ton | 100 | 200 | 300 | 500 | 1000 | 1500 | 2000 | |

| Max.System pressure | Mpa | 24 | 22 | 24 | 25 | 25 | 27 | 25 | |

| Stroke of movable working table | mm | 160 | 150 | 150 | 150 | 150 | 150 | 150 | |

| Opening height | mm | 370 | 380 | 380 | 450 | 500 | 550 | 800 | |

| Height of working platform from ground | mm | 950 | 1050 | 1080 | 1185 | 1365 | 1500 | 2100 | |

| Upward speed of movabale working table | mm/s | 120 | 90 | 80 | 80 | 80 | 70 | 82 | |

| Returning speed of movabale working table | mm/s | 110 | 105 | 90 | 80 | 80 | 80 | 92 | |

| Movable working table size | L-R between column | mm/s | 420 | 520 | 580 | 710 | 900 | 1100 | 1400 |

| F-B Rim | mm/s | 420 | 500 | 540 | 640 | 880 | 1050 | 1380 | |

| Overall dimension | L-R | mm | 1050 | 1130 | 1200 | 1440 | 1640 | 200 | 2505 |

| F-B | mm | 1080 | 1040 | 1165 | 1370 | 1860 | 2090 | 2545 | |

| H | mm | 1790 | 1840 | 1895 | 2080 | 2500 | 2835 | 3860 | |

| Motor power | KW | 5.5 | 5.5 | 7.5 | 15 | 22 | 22 | 30 | |

| Weight (Approx.) | Kgs | 1650 | 2400 | 3300 | 5500 | 9800 | 20000 | 42000 | |

1. The frame structure of Hydraulic press for minting is designed by mechanical analysis, welded with high quality steel material, with good overall rigidity and high compressive strength.

2. Quickly lowering the cylinder to set up the upper pressure type hydraulic cylinder, with high flat temperature.

3. Pressure, stroke, holding pressure, etc. can be adjusted according to the requirements of the pressing process.

4. CDOCAST Hydraulic press for minting comes with Infrared protection, safer operation.

A: Selecting the correct press tonnage is critical for quality and efficiency. We recommend the optimal model based on a thorough analysis of three key factors: the raw material of your product, the final product dimensions, and the intricacy of the design/pattern to be stamped. This ensures you get a press that delivers flawless results without under or over-investing.

A: Generally, we do not recommend combining these functions into a single machine. The primary reasons are:

*Different Dies & Process: Each process requires dedicated dies, and frequent die changes in production are impractical and inefficient.

*Different Technical Requirements:

The Hydraulic Punching Machine requires an extreme, instantaneous impact force with a very short stroke. It operates like a paper hole puncher, demanding “speed, precision, and power,” with high requirements for machine rigidity and the hydraulic system’s burst pressure.

The Hydraulic Stamping Machine requires stable, continuous, and uniform pressure, often with a pressure-holding function. It works like a precision printing press, needing even pressure across the entire mold to ensure sharp, consistent, and deep-struck details. It demands extremely high precision and stability in pressure control.

A: The servo motor drive offers significant advantages:

*Energy Efficiency & Noise: Servo-driven presses are remarkably quieter and more energy-efficient, creating a better working environment and reducing operating costs.

*Precision Control: The servo motor allows for infinite and highly precise pressure adjustments, whereas standard motors have limited control. For products like 1g-200g gold bars, where exquisite detail is critical, we strongly recommend a servo-driven press for its superior pressure precision.

A: Both have their merits for specific applications:

*Four-Column Press: Offers superior structural stability and excellent pressure distribution, making it ideal for high-precision tasks. It typically comes at a higher price point.

*Frame Press (C-Type): A robust and cost-effective solution for many applications.

We will recommend the most suitable structure based on your specific product and technical process requirements.

A: We do not recommend using a single press for such a wide weight range. Here’s why:

*Initial Pressure: Every press has a minimum initial pressure (e.g., 50 Ton for a 300T press). A 1g bar may only require 10 Ton, meaning the machine’s minimum is still excessive, leading to premature mold wear and damage over time.

*Energy Efficiency: Using a large-capacity press for small products is highly inefficient. The energy consumption (electricity/hydraulic oil) is significantly higher than using a appropriately sized machine, leading to substantial long-term operational waste.

The bolster plates are a critical protective feature. During long-term operation, the press’s bed and slide can develop minor deformations. These installed bolster plates absorb this wear, protecting the main machine’s critical surfaces from damage and ensuring long-term accuracy.

A: The sub-Die holder is essential for safety, efficiency, and quality:

*Pressure Distribution: It helps distribute pressure evenly, which is crucial when using small molds for lightweight bars on a larger press.

*Integrated Ejection System: Our bolster plates and sub-mold holders are designed together with an **automatic ejection system**, making production safer and more efficient.

*Safety & Durability: In case of operator error causing excessive pressure and mold breakage, the sub-mold holder contains the fractured pieces, preventing injury and equipment damage. This also reduces downtime. Furthermore, it supports the mold structure, enhancing rigidity and prolonging the overall mold life.

A: This is generally not feasible. The installation height and stroke of the ejection system must be precisely matched to your press’s shut-off height. A mismatch will prevent the automatic ejection from functioning and could lead to severe equipment damage or safety hazards.

A: Light curtains are a vital operator safety feature. They create an invisible infrared barrier around the pressing area. If a worker’s hand breaks this light beam during operation, the press will immediately stop, preventing potential accidents and ensuring a safe working environment.

A: A water chiller is only necessary if your operation involves continuous, uninterrupted work cycles exceeding 10 hours. For standard shift operations, the built-in cooling system is sufficient.

Selecting the correct press tonnage is critical for quality and efficiency. We recommend the optimal model based on a thorough analysis of three key factors: the raw material of your product, the final product dimensions, and the intricacy of the design/pattern to be stamped. This ensures you get a press that delivers flawless results without under or over-investing.

Generally, we do not recommend combining these functions into a single machine. The primary reasons are:

*Different Dies & Process: Each process requires dedicated dies, and frequent die changes in production are impractical and inefficient.

*Different Technical Requirements:

The Hydraulic Punching Machine requires an extreme, instantaneous impact force with a very short stroke. It operates like a paper hole puncher, demanding “speed, precision, and power,” with high requirements for machine rigidity and the hydraulic system’s burst pressure.

The Hydraulic Stamping Machine requires stable, continuous, and uniform pressure, often with a pressure-holding function. It works like a precision printing press, needing even pressure across the entire mold to ensure sharp, consistent, and deep-struck details. It demands extremely high precision and stability in pressure control.

The servo motor drive offers significant advantages:

*Energy Efficiency & Noise: Servo-driven presses are remarkably quieter and more energy-efficient, creating a better working environment and reducing operating costs.

*Precision Control: The servo motor allows for infinite and highly precise pressure adjustments, whereas standard motors have limited control. For products like 1g-200g gold bars, where exquisite detail is critical, we strongly recommend a servo-driven press for its superior pressure precision.

Both have their merits for specific applications:

*Four-Column Press: Offers superior structural stability and excellent pressure distribution, making it ideal for high-precision tasks. It typically comes at a higher price point.

*Frame Press (C-Type): A robust and cost-effective solution for many applications.

We will recommend the most suitable structure based on your specific product and technical process requirements.

We do not recommend using a single press for such a wide weight range. Here’s why:

*Initial Pressure: Every press has a minimum initial pressure (e.g., 50 Ton for a 300T press). A 1g bar may only require 10 Ton, meaning the machine’s minimum is still excessive, leading to premature mold wear and damage over time.

*Energy Efficiency: Using a large-capacity press for small products is highly inefficient. The energy consumption (electricity/hydraulic oil) is significantly higher than using a appropriately sized machine, leading to substantial long-term operational waste.

The bolster plates are a critical protective feature. During long-term operation, the press’s bed and slide can develop minor deformations. These installed bolster plates absorb this wear, protecting the main machine’s critical surfaces from damage and ensuring long-term accuracy.

A: The sub-Die holder is essential for safety, efficiency, and quality:

*Pressure Distribution: It helps distribute pressure evenly, which is crucial when using small molds for lightweight bars on a larger press.

*Integrated Ejection System: Our bolster plates and sub-mold holders are designed together with an **automatic ejection system**, making production safer and more efficient.

*Safety & Durability: In case of operator error causing excessive pressure and mold breakage, the sub-mold holder contains the fractured pieces, preventing injury and equipment damage. This also reduces downtime. Furthermore, it supports the mold structure, enhancing rigidity and prolonging the overall mold life.

A water chiller is only necessary if your operation involves continuous, uninterrupted work cycles exceeding 10 hours. For standard shift operations, the built-in cooling system is sufficient.

This is generally not feasible. The installation height and stroke of the ejection system must be precisely matched to your press’s shut-off height. A mismatch will prevent the automatic ejection from functioning and could lead to severe equipment damage or safety hazards.

Light curtains are a vital operator safety feature. They create an invisible infrared barrier around the pressing area. If a worker’s hand breaks this light beam during operation, the press will immediately stop, preventing potential accidents and ensuring a safe working environment.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Hydraulic Press For Minting

Contact Our Engineer Team

Hydraulic Punching Machine operation video,Click here you can learn more about how to use our machine

CDOCAST launched a new gold Smelter which is manual tilting, This small coreless induction melting furnaces capable of melting ferrous, non-ferrous, precious metals…..

CDOCAST Vacuum Jewelry Polishing Machine video to help you learn more how our Polishing Machine is working

Gold has been a symbol of wealth, power, and beauty for thousands of years. From ancient civilizations to modern economies, gold coins and bars have played a crucial role in trade, investment, and artistry.