- Call Us: 008615168765707

- Mail Us: [email protected]

Are you looking for Vacuum Powder Making Machine? You are in the right place

CDOCAST Water Metal Atomizer

Water atomization powder making equipment is a process that uses high-speed water flow to break molten metal into fine droplets, which are then rapidly cooled and solidified into metal powder. This technology is widely used in powder metallurgy, 3D printing, coating materials, and other fields. The following is a detailed description of its principle, equipment composition, and key features:

The basic principle of water atomization powder production

1. Preparation of molten metal

-Heating a metal or alloy above its melting point to form a uniform molten liquid metal.

2. High-pressure water flow impact fragmentation

-Molten metal flows out through a guide tube and is impacted by high-pressure (usually 10-50 MPa) water jets, causing the liquid flow to be sheared and torn into tiny droplets.

-The kinetic energy of water overcomes the surface tension of metals to achieve atomization.

3. Rapid cooling and solidification

-The atomized metal droplets are rapidly cooled in water (with a cooling rate of up to 10 ^ 3~10 ^ 6 K/s) to form solid powder.

-The cooling rate affects the microstructure of the powder, such as grain size and phase composition.

4. Powder collection and post-treatment

-Obtain the target particle size of metal powder through steps such as filtration, drying, and sieving.

The main components of water atomization powder equipment

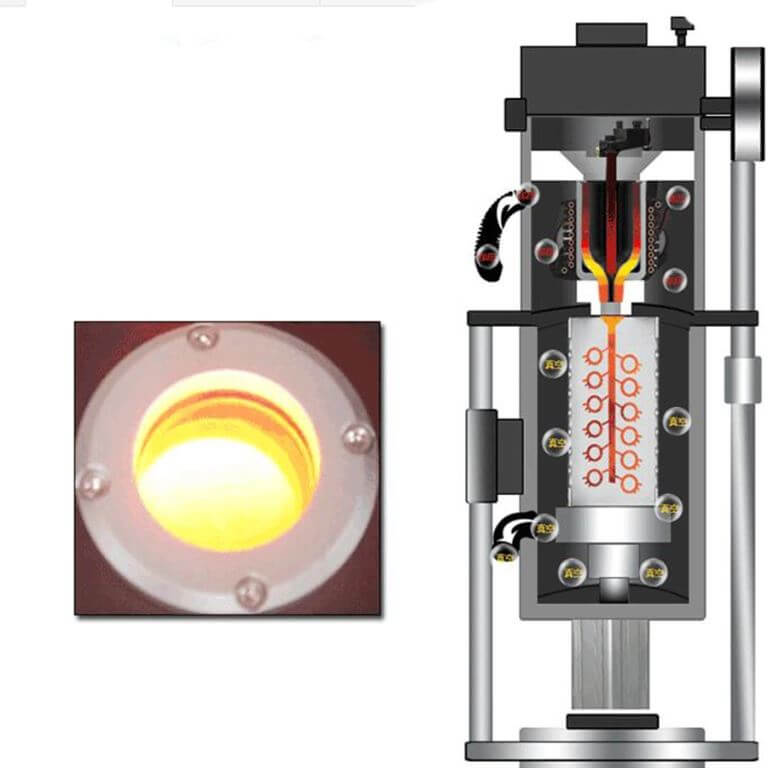

1. Melting system

-Induction furnace or electric arc furnace: used for melting metals, requiring precise temperature control.

-Thermal insulation ladle: stores molten metal and stabilizes flow rate.

2. Atomization system

-High pressure water pump: Provides a stable high-pressure water source.

-Atomizing nozzle: The core component designed to affect the flow pattern (such as annular, laminar, or turbulent) and atomization efficiency.

-Diversion tube: controls the flow rate and flux of molten metal.

3. Cooling and collection system

– Atomization chamber: A closed space where metal droplets and water are mixed and cooled.

– Circulating water cooling device: Prevents excessive water temperature from affecting the atomization effect.

4. Drying and screening system

-Vacuum dryer: removes surface moisture from powder.

-Vibration screen or air classifier: classified by particle size.

Application Fields

1. Powder metallurgy

-Manufacturing mechanical parts such as gears and bearings (iron-based, copper based powder pressing and sintering).

2. Additive Manufacturing (3D Printing)

-Metal powder used for selective laser melting (SLM) (requiring subsequent spheroidization treatment).

3. Thermal spray coating

-Prepare wear-resistant and anti-corrosion coatings (such as nickel based alloy powder).

4. Magnetic materials

-Production of soft magnetic alloy powder (such as iron silicon alloy).

Technical Challenges and Development Trends

1. Challenges

– Control oxidation: by adding antioxidants or post-treatment reduction.

– Improve sphericity: Combine centrifugal atomization or secondary treatment (such as plasma spheroidization).

2. Trends

– Compound atomization: Water-gas combined atomization balances cost and performance.

– Nano powder preparation: ultra-high pressure water atomization combined with rapid cooling technology.

– Intelligent control: real-time monitoring of atomization parameters (water pressure, temperature, flow).

If you need to know more about the powder-making process or specific equipment parameters of a certain type of metal (such as stainless steel, titanium alloy), you can continue to ask questions.

→Click here to watch the video

Click the photo to watch the video

50kg 100kg 150kg 200kg Steel Iron Copper Aluminum Powder Making Machine

50kg 100kg 150kg 200kg Steel Iron Copper Aluminum Powder Making Machine→Click here to watch the video

The process of making metal powder by water atomization has a long history. In ancient times, people poured molten iron into water to make it explode into fine metal particles, which were used as raw materials for making steel; There are also people who pour molten lead water directly into the water to make lead pills. The process principle of making alloy powder by water atomization is the same as that of making water-burst metal liquid in ancient times, but modern technology has greatly improved the efficiency of crushing and manufacturing particles

To make metal alloy powder by high-pressure water atomization method, first, melt the raw metal in the melting furnace, and then the molten gold must be overheated for about 50 degrees and then injected into the tundish. Start the high-pressure water pump before the injection of metel solution, and let the high-pressure water atomization device start the workpiece. The metel liquid in the tundish enters the atomizer through the nozzle at the bottom of the tundish through the beam flow.

The atomizer is the key part for producing metal alloy powder by high-pressure water mist. The atomizer is related to the metal powder-making efficiency, Under the action of the high-pressure water from the atomizer, the molten metal liquid is continuously broken into fine droplets, which fall into the cooling liquid in the water tank and solidify into alloy powder。

In the traditional high-pressure water atomization process for producing metal powder, the metal powder can be collected continuously, but a small amount of metal powder is lost with the atomized water, In the process of producing alloy powder by high-pressure water atomization, the atomized product is concentrated in the atomization device, and then precipitated and filtered (it can be dried if necessary, and generally sent directly to the next process。

A complete set of equipment for producing metal alloy powder by high-pressure water atomization is composed of the following parts:

2: The atomization part, the equipment in this part is non-standard equipment, which should be designed and arranged according to the site conditions of the manufacturer, mainly including the tundish: when the tundish is produced in winter, it needs to be preheated;

Atomizer: the atomizer will come from high-pressure water, The high-pressure water of the pump impacts the metal liquid from the tundish at a predetermined speed and angle, breaking it into metal droplets.

Under the same water pump pressure, the amount of fine metal powder after atomization is related to the atomization efficiency of the atomizer; the atomization cylinder: it is the place where the alloy powder is atomized, crushed, cooled and collected.

3:In order to prevent the ultra-fine alloy powder from being lost with water, the obtained alloy powder should be left for a period of time after atomization, and then placed in the powder collecting box.

4:Post-processing part: powder collecting box: used to collect the atomized alloy powder and separate and remove excess water; drying furnace: dry the wet alloy powder with water;

screening machine: sieve the alloy powder, Out-of-specification coarser alloy powder can be re-melted and atomized as the return material

Integrated Type Powder Making Machine

| Model | CDO-PM10 | CDO-PM20 | CDO-PM30 | CDO-PM50 |

| Power | 20 KW | 30 KW | 40 KW | 45 KW |

| Voltage | 380V, 3 phase, 50/60Hz | |||

| Application metal | Gold、K-Gold、Silver、Copper、Bronze、Zinc、Tin、etc. | |||

| Melting capacity | 10 kg (Copper) | 20 kg (Copper) | 30 kg (Copper) | 50 kg (Copper) |

| Max temperature | 1600 ℃ | 1600 ℃ | 1600 ℃ | 1600 ℃ |

| Melting time | 10-15 min | 15-20 min | 20-25 min | 20-30 min |

| Powder size range | 100-1000 mesh | |||

| Protective gas | Nitrogen / argon | Nitrogen / argon | Nitrogen / argon | Nitrogen / argon |

| Atomization method | Water atomization | |||

| Pump power | 37 KW | 37 KW | 37 KW | 37 KW |

| Water pressure | 10-15Mpa | 10-15Mpa | 10-15Mpa | 10-15Mpa |

| Dimension | 1360*1220*2090 mm | 1450*1290*2090 mm | ||

| Weight | 1050 kg | 1100 kg | 1150 kg | 1200 kg |

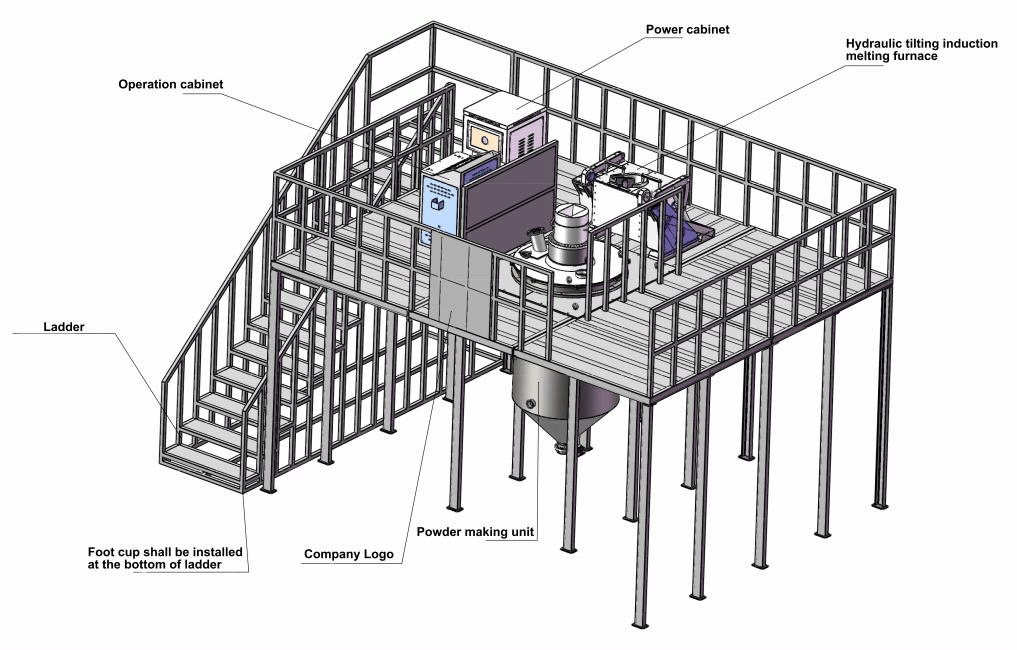

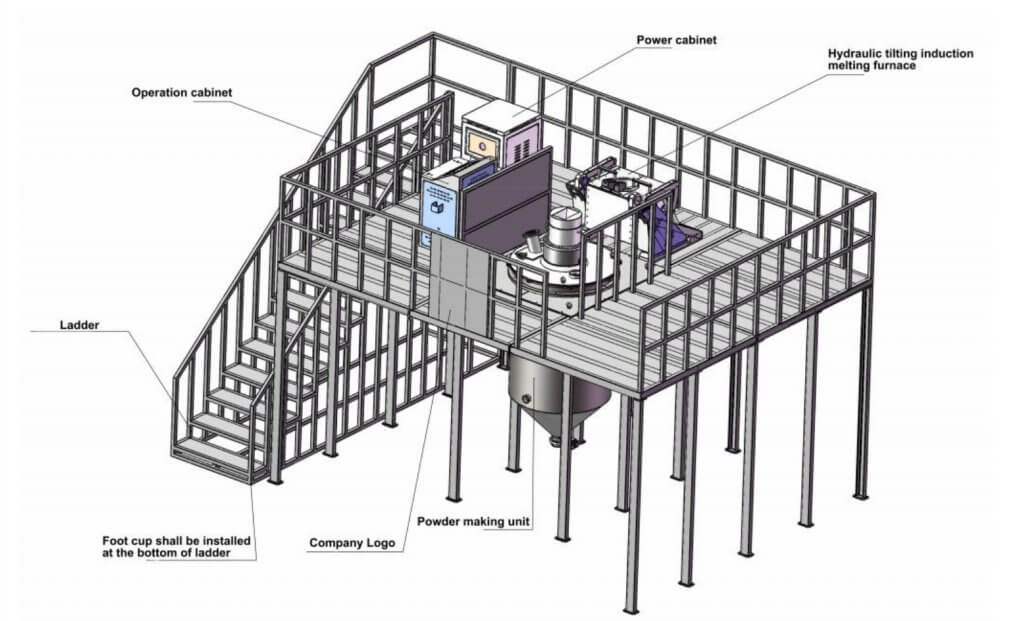

Platform Type Powder Making Machine

| Model | CDO-LPM50 | CDO-LPM100 | CDO-LPM200 | CDO-LPM300 | CDO-LPM500 |

| Voltage | 380V, 3 phase, 50/60Hz | ||||

| Furnace power | 70 KW | 90 KW | 110 KW | 160 KW | 250 KW |

| Melting capacity | 50 kg (Copper) | 100 kg (Copper) | 200 kg (Copper) | 300 kg (Copper) | 500 kg (Copper) |

| Melting time | 20-30 min | 20-40 min | 30-40 min | 30-40 min | 40-50 min |

| Platform size | 4*5*2.5 m | 5*5*2.8 m | 5*5*3 m | 5*5*3 m | 5.8*5*3.2 m |

| Powder size range | 100-1000 mesh | 100-1000 mesh | 100-1000 mesh | 100-1000 mesh | 100-1000 mesh |

| Atomization method | Water atomization | ||||

| Pump power | 55 KW | 55 KW | 65 KW | 65 KW | 75 KW |

| Water pressure | 15-23 MPa | 15-23 MPa | 15-23 MPa | 15-23 MPa | 15-23 MPa |

| Applacation metal | Gold, Silver, Copper, Iron, Stainless steel, Platinum and other high temperature metals | ||||

1. Adopt the electromagnetic induction heating principle with the feature of rapid melting time and high production efficiency, The melting temperature rises quickly, the production efficiency is high, and the particle size distribution is good.

2. With the ability to 24-hour continuously work, can meet the needs of customers with different production output.

3. Come with a vacuum Pump design, the whole granulation is carried out in the vacuum environment to minimize oxidation.

4. CDOCAST vacuum powder making machine can be used for both granulation and pulverizing. With one machine you can do both purposes.

5. This Vacuum powder making machine covers a very small production area and is easy to operate. No engineer needs to sent to do the on-site installation.

6. The Vacuum powder making machine with different capacity can be customized according to customer’s demand, and the maximum capacity can reach 100 kg per batch.

7. The brand-new integrated furnace body structure design helps to improve the performance of powder making.

8. The metal smelting process can be protected by inert gas to reduce oxidation.

Water atomized powder is a metal or alloy powder prepared by high-pressure water atomization technology. It is widely used in powder metallurgy, 3D printing, magnetic materials, welding materials and other fields. Its core features are as follows:

1. Particle morphology and structure

-Irregular shape: During the water atomization process, the molten metal droplets are rapidly cooled under the impact of high-pressure water flow, forming irregular shapes (such as spherical, flaky or dendritic) with high surface roughness.

-Surface oxide layer: Due to the contact between water and high-temperature metal, an oxide layer is easily formed on the surface of the powder (subsequent reduction treatment is required).

-Satellite powder and hollow powder: Some particles may form “satellite powder” due to collision and adhesion, or “hollow powder” may be formed due to the failure of internal gas to escape.

2. Particle size distribution

-Wide range: The particle size of water atomized powder is usually distributed between 10~150μm, which can be controlled by adjusting parameters such as water pressure and nozzle design.

-Suitable for coarse powder needs: Compared with gas atomized powder (finer and more spherical), water atomization is more suitable for scenes with looser particle size requirements (such as MIM metal injection molding).

3. Chemical composition and properties

-High oxygen content: Oxygen is easily introduced during the water atomization process (H₂O decomposition), and the oxygen content needs to be reduced by vacuum annealing or hydrogen reduction (for example, the oxygen content of iron-based powder can be reduced to less than 0.3%).

-Alloy flexibility: A variety of alloy powders can be prepared (such as stainless steel, tool steel, copper alloy, etc.), but highly active metals (such as titanium and aluminum) require special protection.

4. Process efficiency and cost

-High production efficiency: Water atomization equipment is simple, suitable for large-scale continuous production, and the cost is significantly lower than gas atomization.

-Low energy consumption: No inert gas protection is required, only high-pressure water pumps and cooling systems are required, and energy consumption costs are lower.

5. Application

-Powder metallurgy: automotive parts (gears, bearings), cemented carbide premixed powder.

-Magnetic materials: Preparation of Sendust soft magnetic powder.

-Welding and coating: used as welding rods and thermal spraying materials.

-3D printing (some areas): Binder jetting (Binder Jetting) with low requirements for powder sphericity.

6. Comparison of advantages and disadvantages

| Advantage | Disadvantage |

| Low cost, suitable for large-scale production | Irregular powder shape, poor fluidity |

| Can be used for high melting point alloys | High oxygen content, requires subsequent treatment |

| Simple operation | Low fine powder yield (<20μm) |

7. Comparison with other atomization technologies

-Gas atomization: finer powder, high sphericity, low oxygen content, but high cost, suitable for high-end fields such as aerospace, 3D printing, etc.

-Centrifugal atomization: uniform particles but complex equipment, mostly used for specific alloys (such as titanium powder).

-Water atomization: the king of cost-effectiveness, suitable for industrial applications that are not demanding on cost and shape.

The core competitiveness of water atomized powder lies in low cost and high production capacity, especially suitable for fields with high tolerance for powder shape and oxygen content. If higher purity or sphericity powder is required, gas atomization or plasma atomization process can be considered. The actual selection needs to be comprehensively evaluated in combination with the application scenario, cost budget and post-processing capabilities.

A: Prior to issuing a quotation, we require the following key parameters:

*Target Metal: The specific metal or alloy you intend to atomize (e.g., gold, silver, copper, iron).

*Daily Production Capacity: Your required output in weight per day.

*Particle Size Distribution: The desired powder size range (e.g., 100-200 mesh).

*Particle Shape (Sphericity): Requirements for particle morphology.

*Oxygen Content: Maximum allowable oxygen content in the final powder.

*Application of powder: For refining? 3D print? PM sintering or other purposes?

Providing these details is essential for an accurate proposal. If necessary, we can also produce sample powders for your evaluation.

A: *Water Quality: We recommend using deionized or purified water. Tap water contains high levels of minerals, which can cause scaling, block water lines, and potentially contaminate the final product.

*Cooling Water Circuit: The cooling water for the furnace’s mechanical section is supplied by a closed-loop chiller system. This is an internal cycle with only minimal evaporation loss, requiring only periodic top-ups.

*Atomization Water Circuit: The machine is equipped with a water tank for the high-pressure atomization pump. This water is used to disintegrate the molten metal stream. The resulting water-powder mixture is then separated by a filter press.

*Water Consumption & Reuse: The atomization process is the primary consumer of water. The discharged water will contain simple impurities and residual metal particles. For water recycling, we recommend purchasing an optional filtration unit.

A: The power load varies by process stage:

*Melting Phase: ~45 kW for approximately 20 minutes (requires chiller operation at ~10 kW).

*Holding & Atomizing: ~10 kW for molten metal holding, plus the high-pressure pump at ~55 kW for atomization.

*Separation & Drying: The filter press operates at ~5 kW, followed by the dryer at ~5 kW.

A: All our equipment is standardly certified to the CE marking, demonstrating compliance with European health, safety, and environmental standards. We do not provide UL certification as a standard offering due to its prohibitively high cost, lengthy certification cycle, and general impracticality for custom, special-purpose machinery.

A: Yes, particle size is adjustable through a combination of two key parameters:

By fine-tuning these variables, you can influence the resulting particle size distribution.

A: We offer different models for various metal groups:

*Integrated Atomizer: Ideal for non-ferrous metals like gold, silver, copper, brass, bronze etc.

*Tilting-Type Atomizer: Recommended for high-melting-point precious metals such as platinum and palladium.

*Platform-Type Atomizer: Necessary for stainless steel and iron. These metals require a larger atomization chamber to handle the higher melting temperatures and larger volumes.

A: The machine typically produces powder in the range of 100 to 1000 mesh. It is important to note that the atomizer produces a distribution of particle sizes within a set range. If a specific, tight cut (e.g., 150-200 mesh) is required, the powder must be processed through a separate screening or classifying machine after atomization.

A: Space requirements depend on the machine type:

*Integrated Atomizer: Compact and simple. A room of approximately 4m x 6m is usually sufficient.

*Platform-Type Atomizer: Requires a larger workshop of about 5m x 10m with sufficient height and an overhead crane for handling.

A: *Water Atomization: Uses high-pressure water jets to break up the molten metal stream.

*Powder Characteristics: Irregularly shaped particles, higher oxygen content.

*Our Machine Type: The machine described in this document is a Water Atomization system.

*Gas Atomization: Uses inert gas (e.g., Nitrogen, Argon) jets to disintegrate the melt.

*Powder Characteristics: Highly spherical powder, low oxygen content.

*Application: Essential for applications like 3D Printing (Additive Manufacturing).

We offer both technologies. Please consult with our technical team before ordering to select the correct atomization method for your application.

A: Prior to issuing a quotation, we require the following key parameters:

*Target Metal: The specific metal or alloy you intend to atomize (e.g., gold, silver, copper, iron).

*Daily Production Capacity: Your required output in weight per day.

*Particle Size Distribution: The desired powder size range (e.g., 100-200 mesh).

*Particle Shape (Sphericity): Requirements for particle morphology.

*Oxygen Content: Maximum allowable oxygen content in the final powder.

*Application of powder: For refining? 3D print? PM sintering or other purposes?

Providing these details is essential for an accurate proposal. If necessary, we can also produce sample powders for your evaluation.

A: *Water Quality: We recommend using deionized or purified water. Tap water contains high levels of minerals, which can cause scaling, block water lines, and potentially contaminate the final product.

*Cooling Water Circuit: The cooling water for the furnace’s mechanical section is supplied by a closed-loop chiller system. This is an internal cycle with only minimal evaporation loss, requiring only periodic top-ups.

*Atomization Water Circuit: The machine is equipped with a water tank for the high-pressure atomization pump. This water is used to disintegrate the molten metal stream. The resulting water-powder mixture is then separated by a filter press.

*Water Consumption & Reuse: The atomization process is the primary consumer of water. The discharged water will contain simple impurities and residual metal particles. For water recycling, we recommend purchasing an optional filtration unit.

A: The power load varies by process stage:

*Melting Phase: ~45 kW for approximately 20 minutes (requires chiller operation at ~10 kW).

*Holding & Atomizing: ~10 kW for molten metal holding, plus the high-pressure pump at ~55 kW for atomization.

*Separation & Drying: The filter press operates at ~5 kW, followed by the dryer at ~5 kW.

A: All our equipment is standardly certified to the CE marking, demonstrating compliance with European health, safety, and environmental standards. We do not provide UL certification as a standard offering due to its prohibitively high cost, lengthy certification cycle, and general impracticality for custom, special-purpose machinery.

A: Yes, particle size is adjustable through a combination of two key parameters:

*Water Pressure: Adjusted via the control switch on the high-pressure pump.

*Molten Metal Flow Rate: Controlled by the nozzle aperture size at the bottom of the tundish (flow control funnel).

By fine-tuning these variables, you can influence the resulting particle size distribution.

A: We offer different models for various metal groups:

*Integrated Atomizer: Ideal for non-ferrous metals like gold, silver, copper, brass, bronze etc.

*Tilting-Type Atomizer: Recommended for high-melting-point precious metals such as platinum and palladium.

*Platform-Type Atomizer: Necessary for stainless steel and iron. These metals require a larger atomization chamber to handle the higher melting temperatures and larger volumes.

A: The machine typically produces powder in the range of 100 to 1000 mesh. It is important to note that the atomizer produces a distribution of particle sizes within a set range. If a specific, tight cut (e.g., 150-200 mesh) is required, the powder must be processed through a separate screening or classifying machine after atomization.

A: Space requirements depend on the machine type:

*Integrated Atomizer: Compact and simple. A room of approximately 4m x 6m is usually sufficient.

*Platform-Type Atomizer: Requires a larger workshop of about 5m x 10m with sufficient height and an overhead crane for handling.

A: *Water Atomization: Uses high-pressure water jets to break up the molten metal stream.

*Powder Characteristics: Irregularly shaped particles, higher oxygen content.

*Our Machine Type: The machine described in this document is a Water Atomization system.

*Gas Atomization: Uses inert gas (e.g., Nitrogen, Argon) jets to disintegrate the melt.

*Powder Characteristics: Highly spherical powder, low oxygen content.

*Application: Essential for applications like 3D Printing (Additive Manufacturing).

We offer both technologies. Please consult with our technical team before ordering to select the correct atomization method for your application.

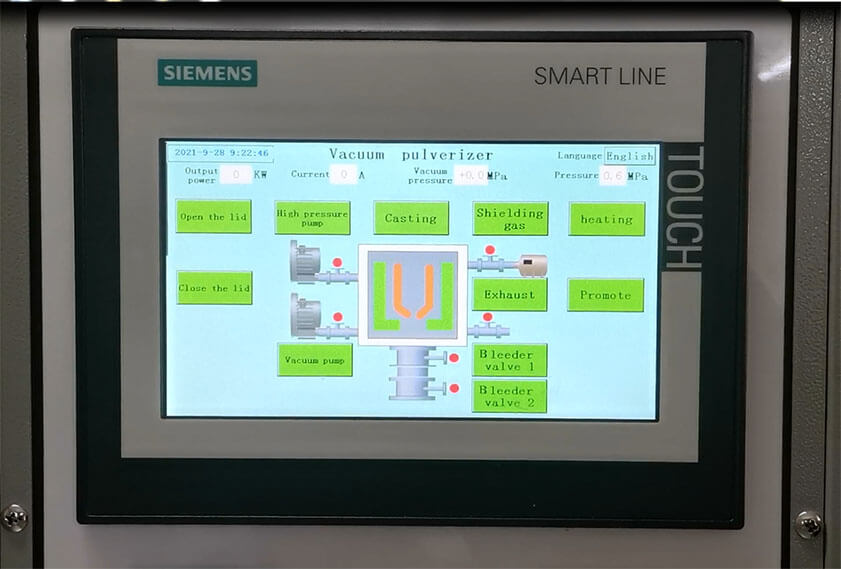

Siemens PLC control panel can be set up in multiple languages,all operations can be done with touching of the screen

The dual purpose casting machine can be customized to produce powder or granule depending on the size of metal you want

Every detail of the CDOCAST vacuum powder casting machine has been improved to advanced technology

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST vacuum powder making machine

Contact Our Engineer Team

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

Video of Jewelry Vacuum Pressurized Casting Machine, you can learn more how the jewelry is cast

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….