- Call Us: 008615168765707

- Mail Us: [email protected]

Are you looking for the most Economical Jewelry Continuous Casting Machine In china,INQUIRY NOW!

*Elevate Your Metal Production with Next-Generation Jewelry Continuous Casting Technology

In the world of precision metal casting, innovation meets craftsmanship through our advanced *Downward Continuous Casting Machine. Engineered for versatility and exceptional performance, these machines empower jewelers, minting authorities, research laboratories, and specialized alloy producers to transform raw materials into flawlessly structured outputs―be it bars, plates, or tubes―with unmatched consistency and control.

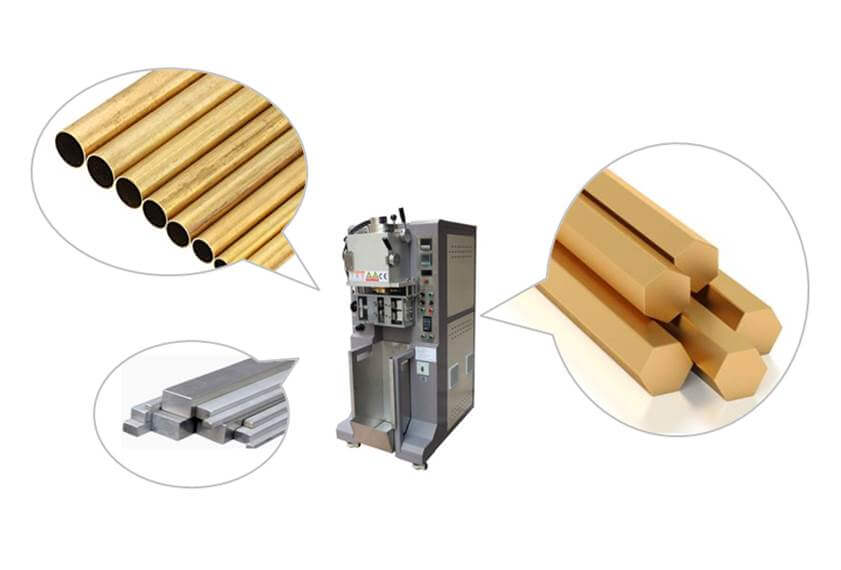

CDOCAST Jewelry continuous casting machine is designed to draw small volumes of different shapes of precious metals such as gold, silver, karat gold, copper alloys, etc. This continuous casting machine can melt and cast types of metal into different shapes, like rod, wire, from(6-20mm), strip, bar. The casting speed is adjustable at about 200mm/min, and the melting capacity ranges from 3kg-30kg per batch.

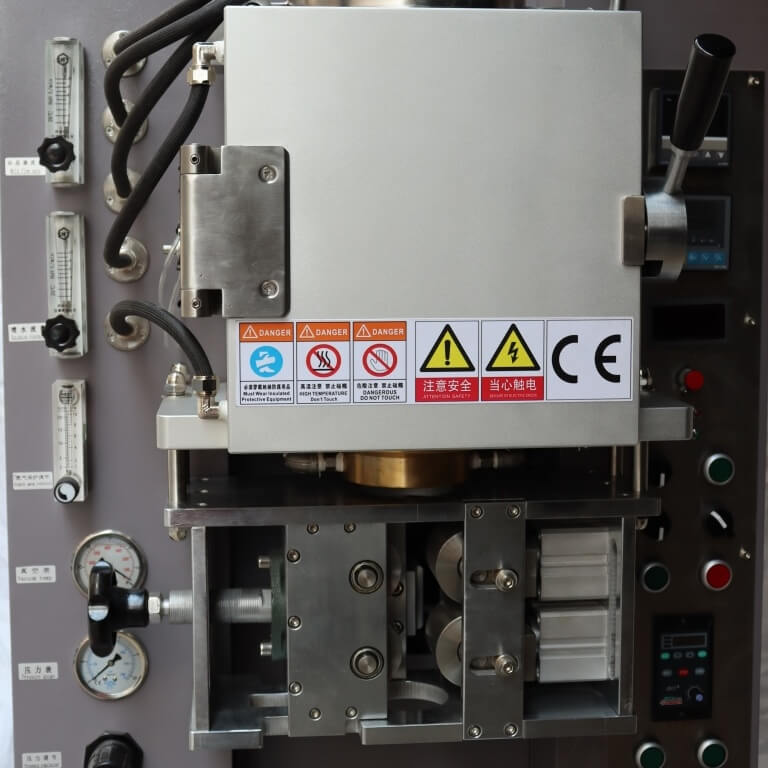

CDOCAST Precious Metal continuous casting machines are fitted with an inert gas protection device to minimize oxidation of the metal and, in the case of karat gold drawing,

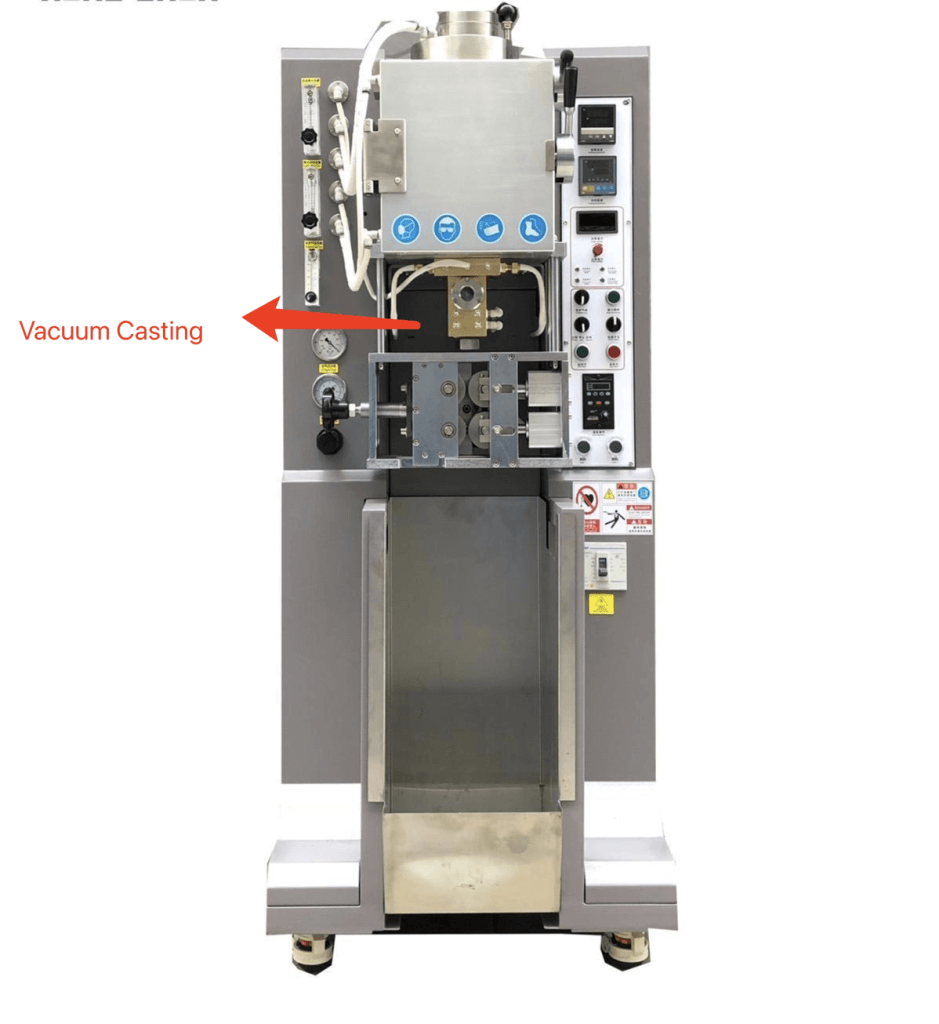

An optional vacuum Casting design allows the entire process to be carried out under vacuum conditions if you want to cast K gold or special Metal alloy. A separate vacuum Casting Chamber will be designed according to the client’s requirement, which means the melting& casting will both be under a vacuum condition to prevent any special metal alloy will oxidizing during the casting process. The vacuum continuous casting machine is ideal for the K-gold, copper alloy, and brass alloy casting.

CDOCAST Continuous casting machines adopt the most advanced medium-frequency induction heating technology, which allows super high temperatures to be reached in a very short time and therefore meets the requirements for continuous casting of most metals.

*Unmatched Flexibility for Precious and Non-Ferrous Metals**

Ideal for processing:

✔ Gold (all karats, including custom alloys)

✔ Silver

✔ Copper

✔ Karat Gold Blends

Our systems accommodate casting capacities from 1 kg to 30 kg, offering tailored solutions for both boutique jewelry studios and high-output industrial environments.

*Please note: Due to extreme melting point requirements, this system is not suitable for platinum or palladium.

| Model | CDO-JC15 | CDO-JC25 | CDO-JC30 | CDO-JC35 |

| Power | 15kw | 25kw | 30kw | 35kw |

| Voltage | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz | Three phase 380V, 50/60Hz |

| Suitable Metal | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys | Gold, Silver, Copper, Brass, Bronze, and their alloys |

| Melting Time | About 5-6 mins | About 5-6 mins | About 15-30 mins | About 15-30 mins |

| Casting speed | 10-20cm/m | 10-20cm/m | 10-20cm/m | 10-20cm/m |

| Capacity | Gold:3.0 kg Silver: 2.0kg Copper:1.5kg |

Gold:6.0 kg Silver: 4.0kg Copper:3.0kg |

Gold:10.0 kg Silver: 6.0kg Copper:5.0kg |

Gold:20.0 kg Silver:11.0kg Copper:10.0kg |

| Gas | Argon Gas or Nitrogen | Argon Gas or Nitrogen | Argon Gas or Nitrogen | Argon Gas or Nitrogen |

| Temperature | 1600℃ | 1600℃ | 1600℃ | 1600℃ |

| Overall Size | 800*600*1650mm | 900*700*1750mm | 1000*800*1850mm | 1000*800*1850mm |

| Machine Weight | 200kg | 220kg | 240kg | 250kg |

1. CDOCAST Jewelry Continuous Casting Machine Adopts intermediate frequency induction heating technology, with the advantage of high power and fast melting, and the highest temperature can reach 1300°C. It has a strong intermediate frequency stirring force, which can lead to a high degree of uniformity of the metal, which is especially helpful for the casting of gold, silver, and copper alloys.

2. Equipped with independent temperature control to continuously monitor the temperature during the entire draw process.

3. Comes with the built-in continuous temperature measurement system, easy to monitor the state of metal lead casting, which leads to the best density and quality of the final product.

4. Design with the ability to work 24 hours per day, this function ensures maximum productivity to meet the high production demands of some customers.

5. Power traction casting can realize drawing pipes, drawing rods, drawing sheets, and drawing strip pipes, which have the characteristics of high speed and high density of finished products. It has the unique magnetic stirring induction heating function to make the metal smelt more uniformly and increase the casting speed.

6. Special device is designed for pulling for automatic detection of slippage phenomena between the roller and the semi-finished product.

7. If a rapid cooling process is required, a water spray system can be installed to cool the semi-finished product directly.

8. Each continuous casting machine is equipped with advanced hydraulic shears for easy cutting of semi-finished products.

9. Abnormal alarm system, it will automatically stop when an abnormality occurs, so as to protect the machine to the greatest extent and prevent damage to the machine.

10. Different capacities can be customized, down-draw casting, effectively reduce the sand hole of the workpiece, and meet the requirements of deep processing.

From intricately designed jewelry components to standardized minting blanks and R&D prototypes, our Downward Continuous Casting Machine delivers:

✔ Bars & Plates: Perfect for rolling mills, stamping, and fabrication

✔ Tubes & Custom Profiles: Ideal for decorative, industrial, or architectural applications

✔ Tailored Dimensions: Customizable molds and continuous casting parameters ensure products match exact customer specifications.

1. Medium-Frequency Melting Technology

Achieve rapid, uniform melting with exceptional temperature stability—critical for preserving material properties and ensuring defect-free results.

2. Optional Hydraulic Shear System

Streamline production of large plates and continuous bars with an integrated hydraulic shear that automatically cuts cast products to desired lengths. No manual handling, no compromise on precision.

3. Intuitive Touchscreen Control

Take command of the entire casting process through a user-friendly digital interface. Monitor temperatures, control casting speed, and save custom profiles for different metals and shapes.

4. Vacuum Casting Upgrade

For oxidation-sensitive metals and alloys, our optional vacuum chamber attachment ensures melt and cast processes occur in an oxygen-free environment, preserving material purity and surface quality.

Whether you’re crafting limited-edition jewelry, producing investment-grade minted products, or pioneering new alloys in a laboratory setting, this machine offers:

– Repeatable, high-yield production cycles

– Customization at every stage—from mold design to automation features

– Enhanced metal integrity via controlled solidification and reduced oxidation

▶ Jewelry Manufacturing: Custom karat gold casting

▶ Mint & Medallion Production: Consistent-quality blank formation

▶ R&D and Specialty Alloy Development: Experimental casting under controllable conditions

▶ Industrial Metal Fabrication: Copper and silver parts for technical applications

We don’t just build machines—we enable possibilities. With configurable options ranging from vacuum capabilities to smart automation, our Downward Continuous Casting Machine grows with your ambition.

Explore the capabilities of our casting systems. Reach out today to discuss your production requirements—let’s engineer the right solution together.

Q1. What types of metals is this casting machine suitable for? Can it be used for platinum or aluminum?

A: This machine is generally used for casting rods, plates, and bars from gold (especially Karat gold), silver, and pure copper.

*Platinum: Its melting point is too high. The graphite casting mold cannot withstand the extreme temperatures and would crack.

*Aluminum: Its rapid solidification rate poses a challenge. During downward pulling, the cast product is highly prone to breaking due to premature solidification.

Q2. What is the casting principle?

A: Molten metal is forced to cool and solidify within a mold (crystallizer). It is then continuously pulled downward via a traction wheel system, enabling a true continuous casting process.

Q3. How do I select the right Continuous Casting Machine for my needs?

A: To provide an accurate recommendation and quotation, we need to know your specific requirements:

1. Your raw material type.

2. The dimensions of your desired finished product.

3. Your target daily production output.

Q4. Why should I choose Downward Continuous Casting Machine?

A: Our Downward Continuous Casting Machine is ideal for small-batch, precision casting. A key advantage is the hydrostatic pressure from the molten metal bath during the pulling process. This pressure promotes:

Enhanced Density & Superior Yield: Products are denser and have a higher yield rate compared to some upward casting methods.

Exceptional Surface Finish: The same pressure results in a remarkably smooth, flat cast surface with minimal defects (e.g., wrinkles). This superior finish often eliminates the need for extensive subsequent surface machining or polishing.

Reduced Precious Metal Loss: Minimizing post-casting machining directly reduces material loss in the form of swarf, making it an ideal solution for jewelry manufacturers focused on material efficiency.

Q5. What are the achievable dimensions for cast bars and plates?

A: Plates/Strips: Width from a minimum of 20mm up to a maximum of 150mm.

Bars/Rods: Diameter from a minimum of 20mm up to a maximum of 80mm.

Q6. Can this casting machine cast both plates and bars simultaneously?

A: This is not recommended. Optimal casting requires specialized molds:

– Flat molds are best for plates/strips.

– Round molds are best for bars/rods.

Different mold shapes typically require different crystallizers to achieve the best cooling performance. A machine is usually configured for one type of crystallizer, and retrofitting is complex and impractical.

Q7. What temperature should I set for melting?

A: Generally, set the temperature several tens of degrees Celsius above the metal’s melting point. Examples:

*Gold (Melting Point ~1064°C): Set Point ~1080°C

*Pure Copper (Melting Point ~1083°C): Set Point ~1120°C

*Karat Gold (contains Cu/Ag): Temperature can be adjusted approximately ±20°C around the pure gold setting depending on the specific alloy.

Q8. Can this casting machine operate continuously 24 hours a day?

A: Yes, continuous 24/7 operation is achievable, provided that adequate supporting cooling equipment is maintained.

Q9. How do I set the correct casting speed?

A: Once the metal reaches the set temperature and is fully molten in the crucible, start with a slow initial speed set via the machine’s speed regulator. After a portion of the product has been successfully cast, gradually increase the casting speed. As a general rule, smaller product cross-sections require slower casting speeds.

Q10. Why does my product have surface cracks?

A: Potential causes include:

*Crystallizer Cooling Temperature Too Low: Causes differential contraction between the surface and interior, leading to shell cracking.

*Casting Speed Too High: The semi-solidified shell is torn by the pulling action before it gains sufficient strength.

*Melting Temperature Too Low: Metal is not fully liquid, affecting fluidity and solidification behavior.

Q11. Why does the product frequently fail to pull or break and fall during casting?

A: Breakage during downward casting is often heavily influenced by the cooling rate. If cooling is too rapid, the product solidifies prematurely before the pulling point, causing the pull rod to break it. Solutions involve readjusting:

① Crystallizer water temperature (e.g., typically 60-80°C for Karat gold).

② Crystallizer water flow rate.

③ Secondary cooling spray position (e.g., adjust the spray position closer to the traction wheel; positioning it too high can cause the section being pulled to solidify too early).

Q12. How is oxidation prevented, especially for metals like Karat gold?

A: Our machine can be equipped with an inert gas protection system. Users can introduce high-purity argon into the furnace chamber to prevent oxidation. For the ultimate protection, we offer models with a fully sealed vacuum casting chamber, where the entire process occurs in a controlled vacuum environment.

Q13. How can I cut the finished product?

A: Our Continuous Casting Machine can be optionally equipped with a Hydraulic Shear, designed for cutting the finished product (capable of cutting materials up to 20mm thick * 150mm wide).

Q14. How is the finished wire collected during casting?

A: Our Continuous Casting Machine can be optionally equipped with a Wire Collecting Spool for coiling the cast wire.

Q15. How is raw material replenished during continuous casting?

A: Our Continuous Casting Machine can be optionally equipped with a Feeder, allowing for the addition of material into the crucible during the casting process without interruption.

Q16. Why won’t the product connect properly with the pull rod?

A: Potential causes include:

① The metal material is not fully molten.

② The hook on the pull rod needs re-profiling/deepening to better engage the product.

③ The crystallizer water temperature is too low, causing the product to solidify before the pull rod can hook it effectively.

A: This machine is generally used for casting rods, plates, and bars from gold (especially Karat gold), silver, and pure copper.

*Platinum: Its melting point is too high. The graphite casting mold cannot withstand the extreme temperatures and would crack.

*Aluminum: Its rapid solidification rate poses a challenge. During downward pulling, the cast product is highly prone to breaking due to premature solidification.

A: Molten metal is forced to cool and solidify within a mold (crystallizer). It is then continuously pulled downward via a traction wheel system, enabling a true continuous casting process.

A: To provide an accurate recommendation and quotation, we need to know your specific requirements:

A: Our Downward Continuous Casting Machine is ideal for small-batch, precision casting. A key advantage is the hydrostatic pressure from the molten metal bath during the pulling process. This pressure promotes:

Enhanced Density & Superior Yield: Products are denser and have a higher yield rate compared to some upward casting methods.

Exceptional Surface Finish: The same pressure results in a remarkably smooth, flat cast surface with minimal defects (e.g., wrinkles). This superior finish often eliminates the need for extensive subsequent surface machining or polishing.

Reduced Precious Metal Loss: Minimizing post-casting machining directly reduces material loss in the form of swarf, making it an ideal solution for jewelry manufacturers focused on material efficiency.

A: Plates/Strips: Width from a minimum of 20mm up to a maximum of 150mm.

Bars/Rods: Diameter from a minimum of 20mm up to a maximum of 80mm.

A: This is not recommended. Optimal casting requires specialized molds:

– Flat molds are best for plates/strips.

– Round molds are best for bars/rods.

Different mold shapes typically require different crystallizers to achieve the best cooling performance. A machine is usually configured for one type of crystallizer, and retrofitting is complex and impractical.

A: Generally, set the temperature several tens of degrees Celsius above the metal’s melting point. Examples:

*Gold (Melting Point ~1064°C): Set Point ~1080°C

*Pure Copper (Melting Point ~1083°C): Set Point ~1120°C

*Karat Gold (contains Cu/Ag): Temperature can be adjusted approximately ±20°C around the pure gold setting depending on the specific alloy.

A: Yes, continuous 24/7 operation is achievable, provided that adequate supporting cooling equipment is maintained.

A: Once the metal reaches the set temperature and is fully molten in the crucible, start with a slow initial speed set via the machine’s speed regulator. After a portion of the product has been successfully cast, gradually increase the casting speed. As a general rule, smaller product cross-sections require slower casting speeds.

A: Potential causes include:

*Crystallizer Cooling Temperature Too Low: Causes differential contraction between the surface and interior, leading to shell cracking.

*Casting Speed Too High: The semi-solidified shell is torn by the pulling action before it gains sufficient strength.

*Melting Temperature Too Low: Metal is not fully liquid, affecting fluidity and solidification behavior.

A: Breakage during downward casting is often heavily influenced by the cooling rate. If cooling is too rapid, the product solidifies prematurely before the pulling point, causing the pull rod to break it. Solutions involve readjusting:

① Crystallizer water temperature (e.g., typically 60-80°C for Karat gold).

② Crystallizer water flow rate.

③ Secondary cooling spray position (e.g., adjust the spray position closer to the traction wheel; positioning it too high can cause the section being pulled to solidify too early).

A: Our machine can be equipped with an inert gas protection system. Users can introduce high-purity argon into the furnace chamber to prevent oxidation. For the ultimate protection, we offer models with a fully sealed vacuum casting chamber, where the entire process occurs in a controlled vacuum environment.

A: Our Continuous Casting Machine can be optionally equipped with a Hydraulic Shear, designed for cutting the finished product (capable of cutting materials up to 20mm thick * 150mm wide).

A: Our Continuous Casting Machine can be optionally equipped with a Wire Collecting Spool for coiling the cast wire.

A: Potential causes include:

① The metal material is not fully molten.

② The hook on the pull rod needs re-profiling/deepening to better engage the product.

③ The crystallizer water temperature is too low, causing the product to solidify before the pull rod can hook it effectively.

A: Our Continuous Casting Machine can be optionally equipped with a Feeder, allowing for the addition of material into the crucible during the casting process without interruption.

A: This machine is generally used for casting rods, plates, and bars from gold (especially Karat gold), silver, and pure copper.

*Platinum: Its melting point is too high. The graphite casting mold cannot withstand the extreme temperatures and would crack.

*Aluminum: Its rapid solidification rate poses a challenge. During downward pulling, the cast product is highly prone to breaking due to premature solidification.

A: Molten metal is forced to cool and solidify within a mold (crystallizer). It is then continuously pulled downward via a traction wheel system, enabling a true continuous casting process.

A: To provide an accurate recommendation and quotation, we need to know your specific requirements:

1. Your raw material type.

2. The dimensions of your desired finished product.

3. Your target daily production output.

A: Our Downward Continuous Casting Machine is ideal for small-batch, precision casting. A key advantage is the hydrostatic pressure from the molten metal bath during the pulling process. This pressure promotes:

Enhanced Density & Superior Yield: Products are denser and have a higher yield rate compared to some upward casting methods.

Exceptional Surface Finish: The same pressure results in a remarkably smooth, flat cast surface with minimal defects (e.g., wrinkles). This superior finish often eliminates the need for extensive subsequent surface machining or polishing.

Reduced Precious Metal Loss: Minimizing post-casting machining directly reduces material loss in the form of swarf, making it an ideal solution for jewelry manufacturers focused on material efficiency.

A: Plates/Strips: Width from a minimum of 20mm up to a maximum of 150mm.

Bars/Rods: Diameter from a minimum of 20mm up to a maximum of 80mm.

A: This is not recommended. Optimal casting requires specialized molds:

– Flat molds are best for plates/strips.

– Round molds are best for bars/rods.

Different mold shapes typically require different crystallizers to achieve the best cooling performance. A machine is usually configured for one type of crystallizer, and retrofitting is complex and impractical.

A: Generally, set the temperature several tens of degrees Celsius above the metal’s melting point. Examples:

*Gold (Melting Point ~1064°C): Set Point ~1080°C

*Pure Copper (Melting Point ~1083°C): Set Point ~1120°C

*Karat Gold (contains Cu/Ag): Temperature can be adjusted approximately ±20°C around the pure gold setting depending on the specific alloy.

A: Yes, continuous 24/7 operation is achievable, provided that adequate supporting cooling equipment is maintained.

A: Once the metal reaches the set temperature and is fully molten in the crucible, start with a slow initial speed set via the machine’s speed regulator. After a portion of the product has been successfully cast, gradually increase the casting speed. As a general rule, smaller product cross-sections require slower casting speeds.

A: Potential causes include:

*Crystallizer Cooling Temperature Too Low: Causes differential contraction between the surface and interior, leading to shell cracking.

*Casting Speed Too High: The semi-solidified shell is torn by the pulling action before it gains sufficient strength.

*Melting Temperature Too Low: Metal is not fully liquid, affecting fluidity and solidification behavior.

A: Breakage during downward casting is often heavily influenced by the cooling rate. If cooling is too rapid, the product solidifies prematurely before the pulling point, causing the pull rod to break it. Solutions involve readjusting:

① Crystallizer water temperature (e.g., typically 60-80°C for Karat gold).

② Crystallizer water flow rate.

③ Secondary cooling spray position (e.g., adjust the spray position closer to the traction wheel; positioning it too high can cause the section being pulled to solidify too early).

A: Our machine can be equipped with an inert gas protection system. Users can introduce high-purity argon into the furnace chamber to prevent oxidation. For the ultimate protection, we offer models with a fully sealed vacuum casting chamber, where the entire process occurs in a controlled vacuum environment.

A: Our Continuous Casting Machine can be optionally equipped with a Hydraulic Shear, designed for cutting the finished product (capable of cutting materials up to 20mm thick * 150mm wide).

A: Our Continuous Casting Machine can be optionally equipped with a Wire Collecting Spool for coiling the cast wire.

A: Our Continuous Casting Machine can be optionally equipped with a Feeder, allowing for the addition of material into the crucible during the casting process without interruption.

A: Potential causes include:

① The metal material is not fully molten.

② The hook on the pull rod needs re-profiling/deepening to better engage the product.

③ The crystallizer water temperature is too low, causing the product to solidify before the pull rod can hook it effectively.

Hydraulic shear is optional attached to the Jewelry Continuous Casting Machine

Vacuum condition is optional and the advanced technology ensure the finished product dense, uniform and shiny

CDOCAST continuous casting machine can cast your precious metals to any desired shape,rod,plate, wire..etc

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Jewelry Continuous Casting Machine

Contact Our Engineer Team

Gold wire, silver wire in the jewelry industry and its electronic industry is very common and important product,Let’s talk about the drawing process of gold and silver wire in detail.

Graphite Crucible & Mould For Mini Gold Melting Furnace,Click here to get more information about how to choose the most suitable graphite crucible & mould

videos Continuous Casting Machine for precious metals . Click the link you can learn more through the video

Jewelry Continuous Casting Machine operation video,Click here you can learn more about how to use our machine