- Call Us: 008615168765707

- Mail Us: [email protected]

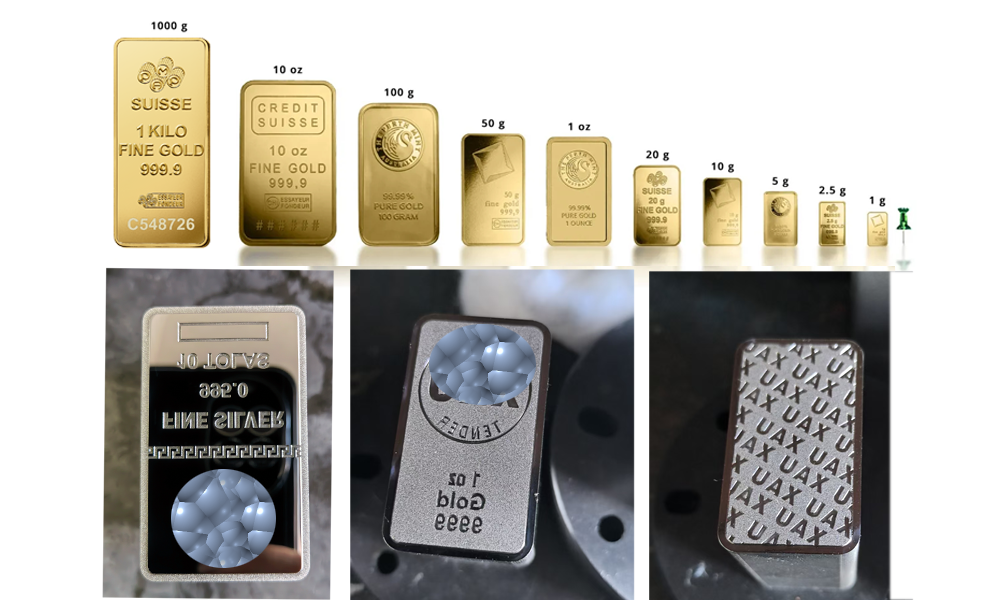

Customized The Die For Gold Silver Minting & Casting Bar

Minting Dies & Stamping Dies for Coin and Bar Production

A minting die is a precision-hardened metal tool used in coin production to imprint intricate designs, logos, text, and shapes onto metal blanks (planchets). These dies are crafted from high-grade steel to withstand the extreme pressures required for striking coins made of gold, silver, copper, zinc, brass, and other metals.

In the minting process, two dies—the obverse (front) die and the reverse (back) die—are precisely aligned within a coin press. When a blank planchet is fed into position, the press applies tremendous force, pressing the dies onto the metal to transfer the engraved design with sharp, high-quality detail.

CDOCAST specializes in manufacturing durable, high-precision minting dies from hardened steel. Each coin typically requires a matched pair of dies (obverse and reverse) to ensure consistent, flawless striking.

Working Principle of Character Stamping on Gold/Silver Bars

The surface stamping of characters on gold and silver bars primarily relies on mechanical pressing technology, where external pressure is applied to imprint the raised characters of the die onto the metal surface, forming permanent recessed markings.

(1)Die Structure:

A convex die is used, featuring raised reverse-carved characters. The gold/silver bar is placed on a flat base, and the die is aligned with the stamping position. Instantaneous high pressure is then applied via a hydraulic press or mechanical stamping machine. Under pressure, the metal undergoes plastic deformation, and the die’s characters are pressed into the surface, creating clear recessed text or patterns. After stamping, the pressure is released, and the bar is removed, completing the process.

(2)Key Principles:

Material Plasticity: Precious metals like gold and silver exhibit excellent ductility, enabling permanent deformation under pressure with minimal rebound.

Pressure Control: Sufficient pressure ensures proper deformation, while excessive force is avoided to prevent uneven thickness or die damage.

Die Hardness: The die material is significantly harder than gold/silver, ensuring long-term durability and consistent imprint precision.

(3)Technical Features:

High Efficiency: Single-press operation enables rapid mass production.

Clear Imprints: High-precision dies produce sharp-edged markings (e.g., purity, brand, serial number) with high legibility.

Eco-Friendly: A cold-working process that generates minimal metal waste, reducing environmental impact.

This efficient and precise mechanical stamping method allows for permanent identification on precious metals, meeting industry standards and branding requirements.

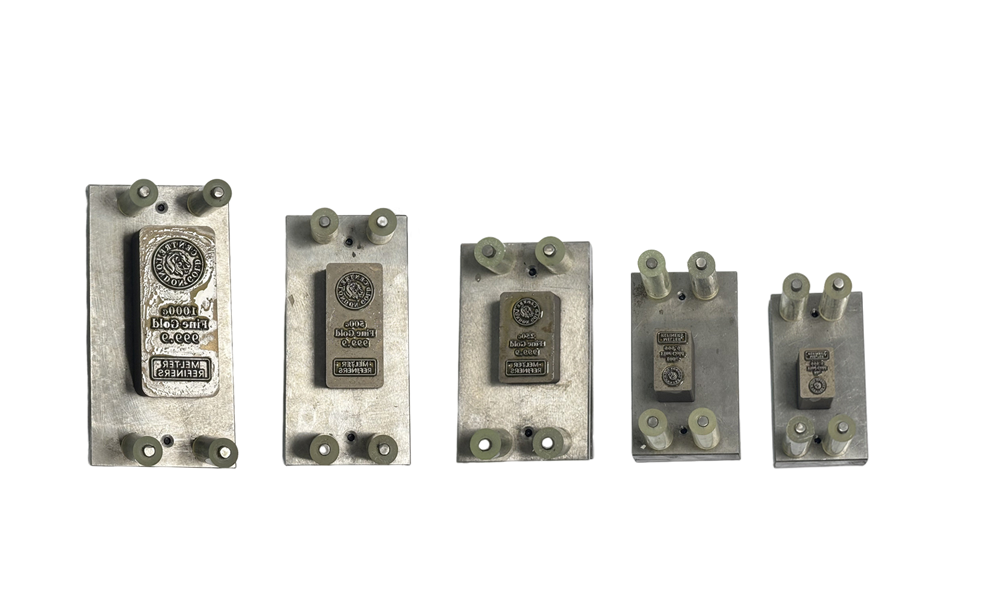

-Minting Die

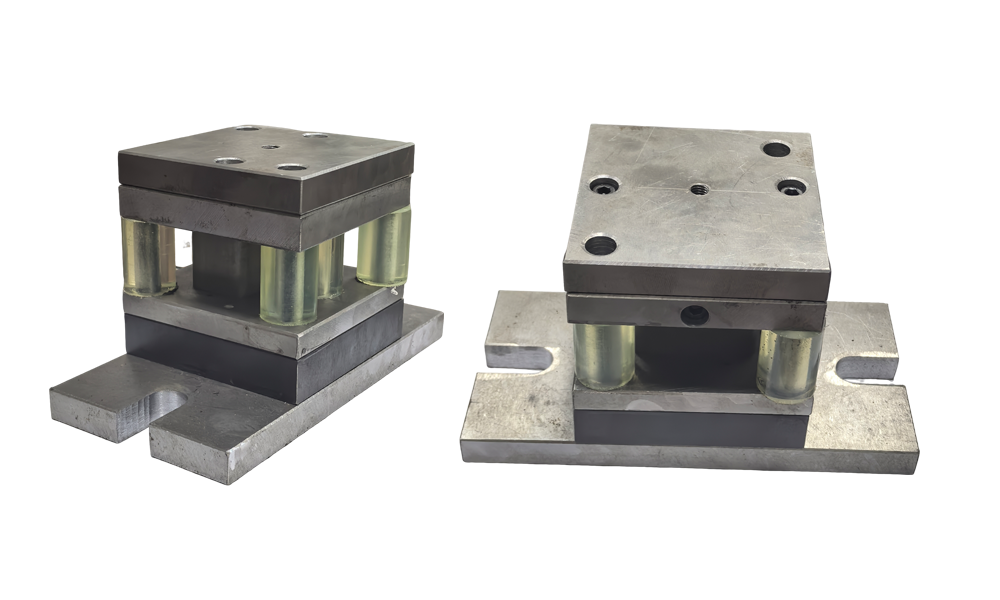

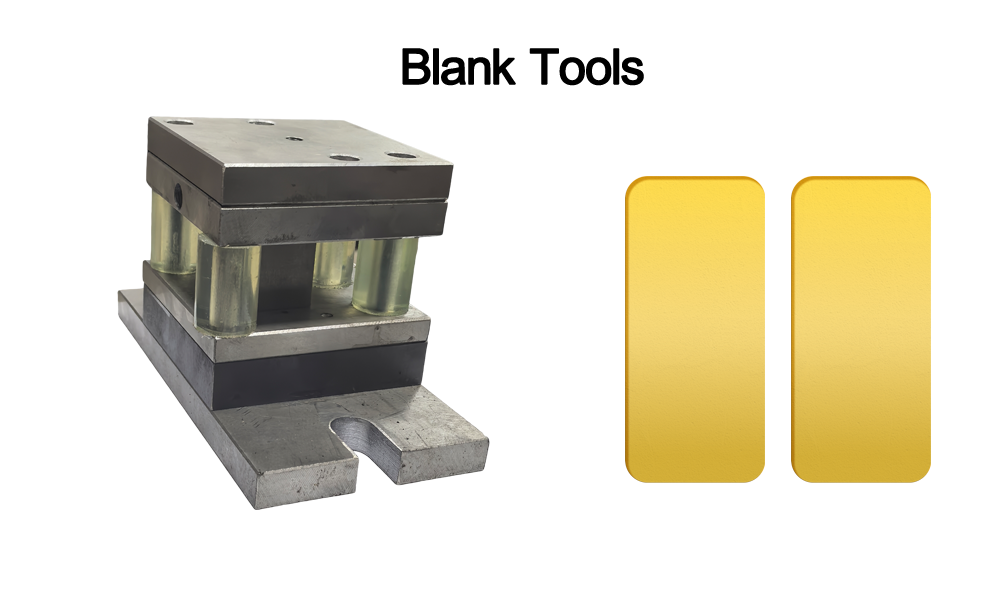

Dual Die Sets: Minted bars usually involve two sets of dies—a blanking die for cutting and a hydraulic die for pressing.

Advanced Design Process: The production begins with 2D/3D drawings, with patterns often on both sides. Complex designs may require 3D modelling, extending the production cycle.

Precision & Complexity: Minting dies are more intricate than casting dies, as they must precisely control the bar/coin’s dimensions and edge serrations (reeding).

-Casting Die

Single Die Set: Cast bars typically require only one set of hydraulic dies for production.

Design Process: The die is created based on 2D drawings of the gold bar, with patterns engraved on only one side.

Simplicity & Tolerance: The die design is relatively simple and does not require strict control over the final dimensions of the gold/silver bars.

Die Making:

The artistic designs on mint coins and medals aren’t etched into each coin – they’re pressed. To press a design onto coins and medals, the Mint needs a stamp called a die. To make a die, the Mint uses another stamp called a hub.

Once the customer approves a design, our engineer turns the line drawing into a sculpted piece of art using digital software. A machine engraves the design onto a copper hub, which shows the positive image the way the artist created it. Dies are like a photo negative, displaying the design in reverse. When the dies stamp the coins or medals, the positive image transfers onto the blank.

To create dies, a wire EDM machine first cuts the steel block into cylindrical sections (3-inch diameter). These cylinders then undergo three-stage heat treatment to achieve the required hardness and stability. Only after this process can the actual die machining begin.

The heat-treated cylinder is further shaped, with one end precision-ground into a cone and polished to a smooth, shiny surface. This cone-shaped workpiece is referred to as a die blank.

The uses DC53 steel for dies because it is strong enough to withstand being forced against other metals in the coin press.

A CNC milling machine precisely engraves the design onto the reusable copper hub. This component serves as a master mold for reproducing the desired pattern and can be reused for multiple production cycles.

After EDM processing, the dies undergo manual polishing to achieve the required surface finish—whether a mirror polish or textured (satin) finish per customer specifications.

A technician then cleans and inspects each die under a microscope, removing minor scratches or imperfections through precision buffing.

Total Lead Time: 7–10 days for the complete die manufacturing process.

1:Transport Protection – During transportation, pay special attention to protecting the die’s surface, as it is highly susceptible to scratches.

2: Anti-Rust Coating & Removal – When the die is not in use, apply anti-rust oil. However, before placing it into the hydraulic press, ensure all oil residue is thoroughly wiped off.

3:Pre-Stamping Cleanliness Check – Before stamping, inspect both the material and die surface to ensure they are free of dust, debris, or contaminants.

4: Mirror Surface Polishing – For dies with mirror-finish backgrounds, perform regular polishing using a wool buffing wheel and specialized polishing compound.

5: Temperature, Humidity & Chemical Control – Store dies in a controlled environment (stable temperature/low humidity) to prevent thermal deformation and corrosion. Avoid strong acid/base exposure, which may degrade metal integrity.

1. Ultra-Precision CNC & EDM Crafted Details

– Our dies combine CNC machining for macro-structure accuracy and EDM (Electrical Discharge Machining) for microscopic refinement, achieving sub-micron (±0.5µm) tolerances on complex geometries.

2. Ultra-Durable DC53 Tool Steel Dies

– Our dies are precision-engineered from DC53 tool steel and undergo 4-stage heat treatment (quenching, tempering, cryogenic, aging), delivering 3X longer lifespan than standard molds. With 62-634 HRC hardness and stress-free stability, they withstand 1M+ strikes without deformation—perfect for high-volume minting.

3. Dual-Surface Precision Dies

– Our EDM-machined, hand-polished dies create simultaneous mirror & satin finishes, delivering coins with sharp contrast, zero defects, and premium tactile quality – perfect for high-end commemorative and bullion production.

4. Safe and Efficient Quick-Change Die System

– We provide hydraulic press solutions equipped with professional die holders permanently mounted on the press. The dies are securely locked into these holders, ensuring both operational safety by eliminating direct handling of heavy dies and enabling rapid die changes within 3-5 minutes. This innovative design allows for efficient switching between different coin and bar productions while maintaining precise alignment every time, maximizing productivity without compromising safety or quality.

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Minting & Casting Die for Coin Bullion

Contact Our Engineer Team

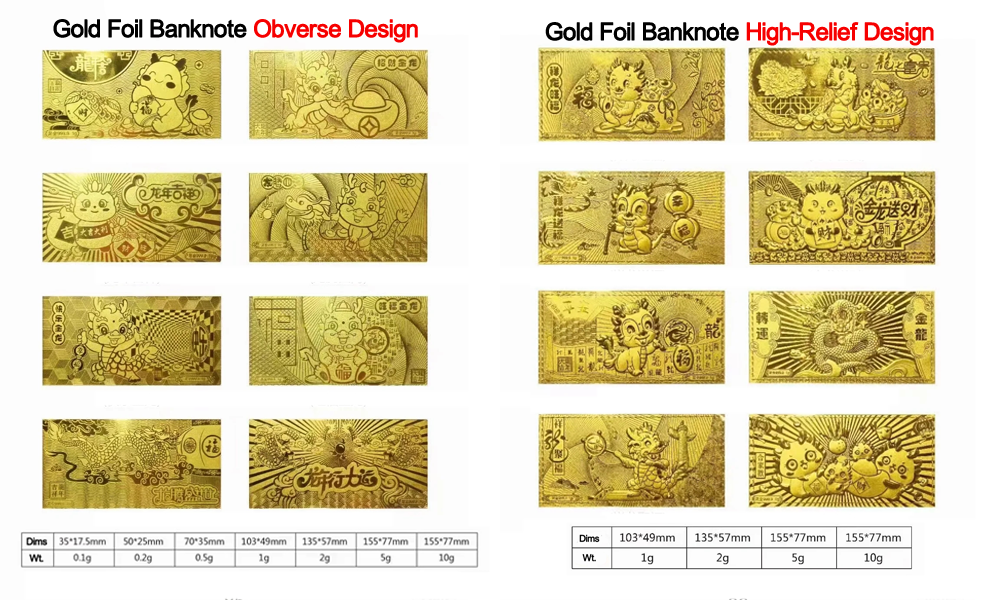

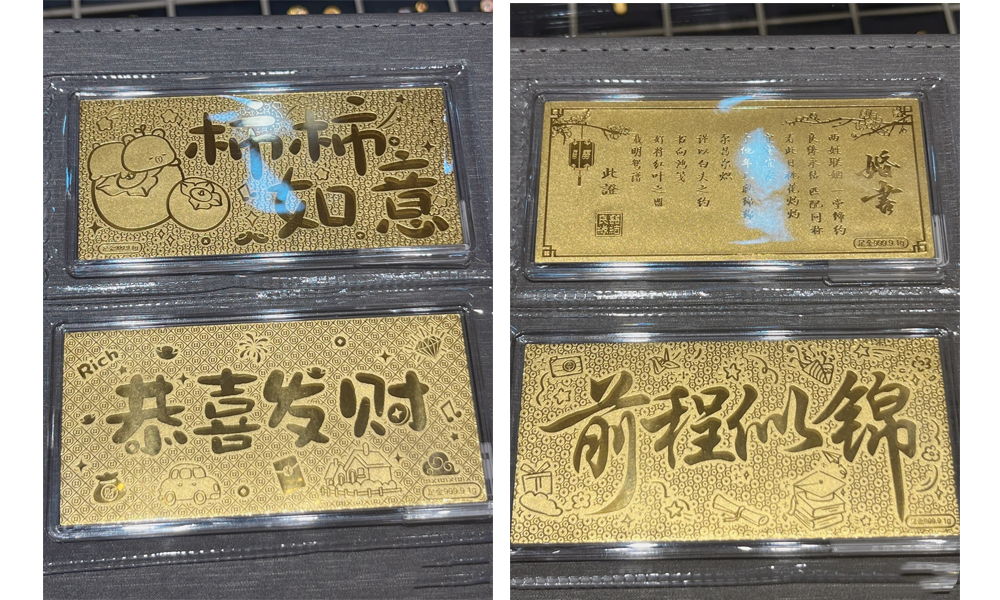

This one guide helps to give you an idea about the production of high-security dies for gold foil banknotes, covering design and manufacturing processes.

CDOCAST provide you the manufacturing process for gold coins and gold bars, from design to final production.

CDOCAST explain the different manufacturing process for the minted bar and casting bar.

This article explains the function and importance of extra-hardened plates in hydraulic presses for minting.