- Call Us: 008615168765707

- Mail Us: [email protected]

Are you looking for Metal Flake Making Machine? You are in the right place

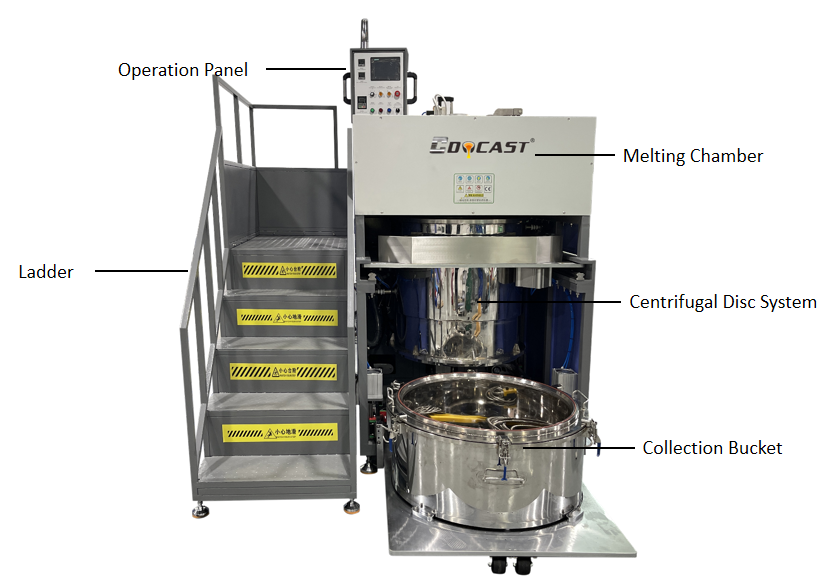

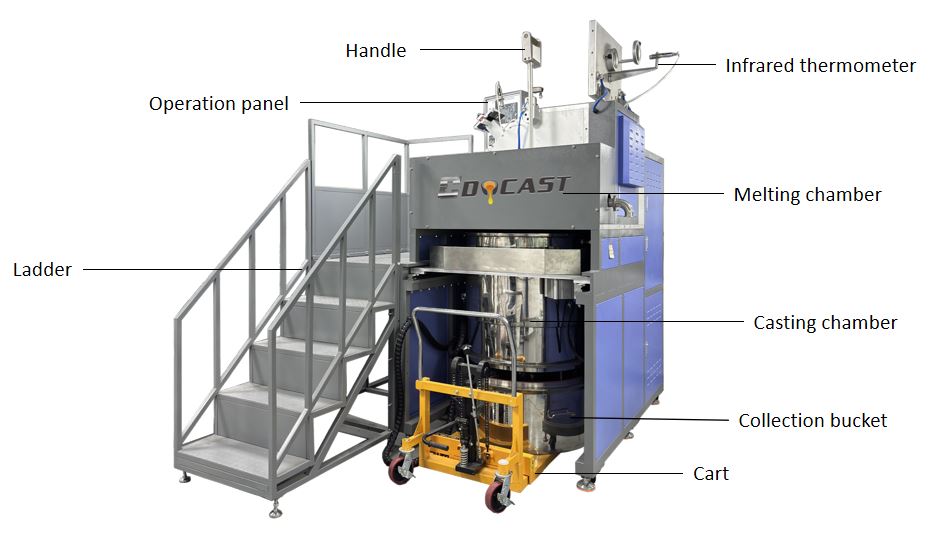

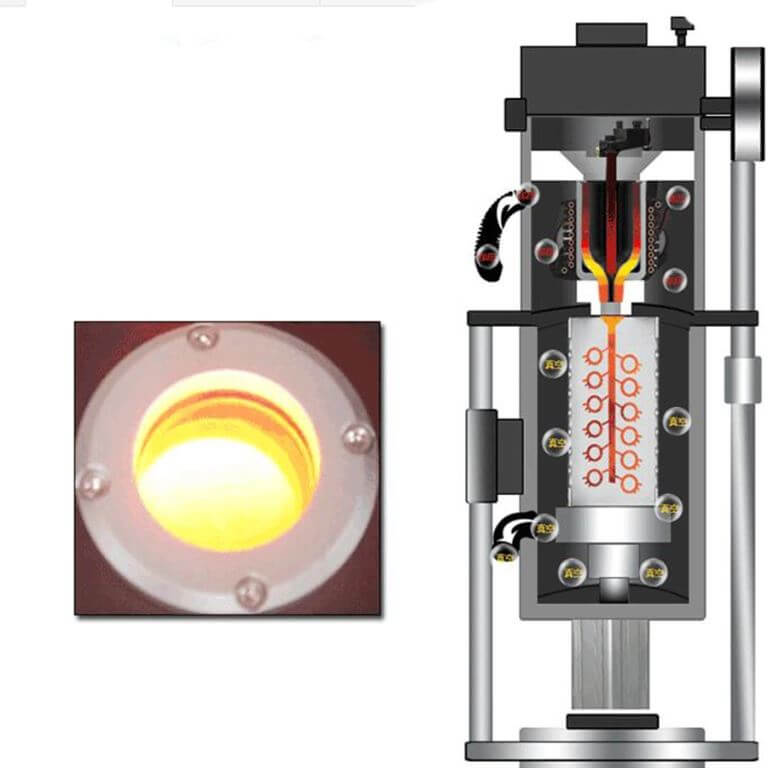

CDOCAST Metal Flake Making Machine is specially designed to make gold, silver, copper, platinum, etc., metal flakes, which greatly improves refining efficiency. It includes a melting chamber, casting chamber, collection bucket, lifting forklift, operating panel, and ladder. It can melt precious metal alloys and process them into metal flakes≤ 0.1mm, which is convenient for subsequent chemical dissolution.

1. Doubled Purification Efficiency

After smelting, the material is directly formed into flakes ≤0.1mm in size by a centrifugal system, facilitating subsequent dissolution in chemical reagents and significantly improving purification efficiency.

2. Virtually No Loss

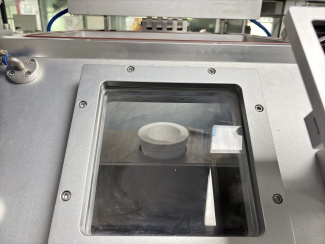

Sealed operation and inert gas protection isolate oxygen throughout the process, preventing high-temperature oxidation.

3. Low Production Cost

The machine is simple to operate and can be completed in one step. Direct recycling reduces material loss.

Click the photo to watch the video

Parameter of Metal Flake Making Machine

| Model number | CDO-FC50 | CDO-FC70 |

| Power source | Three phase 380V±10%, 50/60Hz | Three phase 380V±10%, 50/60Hz |

| Power | 50kw | 70kw |

| Max capacity | 100 KG Gold | 20 KG Platinum |

| Melting time | 10-30 min | 10-15 min |

| Max temperature | 1250℃ | 2000℃ |

| Protective gas pressure | 0.2 MPa(argon or nitrogen) | |

| Air pressure | 0.6-0.8 MPa | 0.6-0.8 MPa |

| Temperature control | PID | PID |

| Cooling water | Water pressure: 0.2-0.4 MPa, flow rate: 3m³/h | |

| Dimension | 2100*2355*2573mm | 2100*2000*2575mm |

| More specifications can be customized | ||

1. This machine prevents oxidation and wear of metals caused by high temperatures during centrifugal rotary blade.

2. It effectively improves product quality and significantly reduces production costs.

3. It improves refining quality, resolves recycling issues, and increases reactor efficiency.

4. This machine offers simple operation, reliable quality, and safe production.

5. Medium-frequency heating is harmless to the human body.

Q1: What is the working principle of the metal flake making machine?

A: The machine uses centrifugal force to transform molten metal into thin flakes. The metal is poured onto a high-speed rotating disc, where it instantly solidifies and is flung into a collection chamber.

Q2: Which metal materials can this metal flake making machine process?

A: This metal flake making machine can work with gold, silver, copper, and platinum. For high-melting-point metals like platinum, a tilting model is recommended to ensure proper melting and handling. For gold, silver, and copper, a standard integrated model is sufficient.

Q3: How thin are the flakes produced by this metal flake making machine?

A: The flakes are generated by the high-speed rotation of the centrifugal system. Under normal operation, they can achieve a remarkably thin, paper-like consistency (≤ 0.1mm).

Q4: What are the advantages of the Metal Flake Making Machine compared to a Powder Making Machine?

A: Our metal flake making machine offers significant benefits:

✔ Lower equipment cost

✔ Minimal auxiliary equipment needed (only a water chiller and dust suction device), compact size, saving space

✔ Lower material loss

✔ Simple operation with no additional processing required

Q5: What is the material loss rate?

A: The loss rate is very low, limited to minor oxidation during melting and minimal dust loss during collection.

Q6: What is the RPM of the centrifugal system?

A: The centrifugal disc operates at an adjustable speed, with a maximum of 1400 RPM.

Q7: What are the consumables and their typical service life?

A: Graphite Crucible: Approximately 50 uses.

Quartz Crucible: Approximately 3 uses.

A: The machine uses centrifugal force to transform molten metal into thin flakes. The metal is poured onto a high-speed rotating disc, where it instantly solidifies and is flung into a collection chamber.

A: This metal flake making machine can work with gold, silver, copper, and platinum. For high-melting-point metals like platinum, a tilting model is recommended to ensure proper melting and handling. For gold, silver, and copper, a standard integrated model is sufficient.

A: The flakes are generated by the high-speed rotation of the centrifugal system. Under normal operation, they can achieve a remarkably thin, paper-like consistency (≤ 0.1mm).

A: Our metal flake making machine offers significant benefits:

✔ Lower equipment cost

✔ Minimal auxiliary equipment needed (only a water chiller and dust suction device), compact size, saving space

✔ Lower material loss

✔ Simple operation with no additional processing required

A: The loss rate is very low, limited to minor oxidation during melting and minimal dust loss during collection.

A: The centrifugal disc operates at an adjustable speed, with a maximum of 1400 RPM.

A: Graphite Crucible: Approximately 50 uses.

Quartz Crucible: Approximately 3 uses.

A: The machine uses centrifugal force to transform molten metal into thin flakes. The metal is poured onto a high-speed rotating disc, where it instantly solidifies and is flung into a collection chamber.

A: This metal flake making machine can work with gold, silver, copper, and platinum. For high-melting-point metals like platinum, a tilting model is recommended to ensure proper melting and handling. For gold, silver, and copper, a standard integrated model is sufficient.

A: The flakes are generated by the high-speed rotation of the centrifugal system. Under normal operation, they can achieve a remarkably thin, paper-like consistency (≤ 0.1mm).

A: Our metal flake making machine offers significant benefits:

✔ Lower equipment cost

✔ Minimal auxiliary equipment needed (only a water chiller and dust suction device), compact size, saving space

✔ Lower material loss

✔ Simple operation with no additional processing required

A: The loss rate is very low, limited to minor oxidation during melting and minimal dust loss during collection.

A: The centrifugal disc operates at an adjustable speed, with a maximum of 1400 RPM.

A: Graphite Crucible: Approximately 50 uses.

Quartz Crucible: Approximately 3 uses.

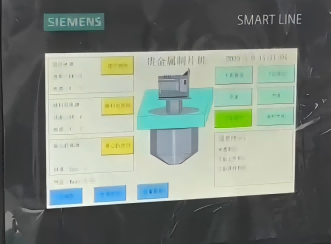

Siemens PLC control panel can be set up in multiple languages,all operations can be done with touching of the screen

Applicable to the production of various precious metals flakes

Sealed inert gas melting environment to reduce oxidation loss

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST Metal Flake Making Machine

Contact Our Engineer Team

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

Video of Jewelry Vacuum Pressurized Casting Machine, you can learn more how the jewelry is cast

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….