Common Issues and Solutions in Gold Silver Bar Casting

Common Issues and Solutions in Vacuum Gold Silver Bar Casting

Precious metal casting is one of the oldest crafts in human history. From ancient coins to modern investment bullion, the casting of gold and silver bars carries multiple values in finance, culture, and technology. This year, with the continuous rise in gold and silver prices, more and more people are joining the ranks of gold and silver bar casting. According to statistics from the London Bullion Market Association, global annual production of investment-grade gold bars exceeds 5,000 tons, and silver bars exceed 25,000 tons. This vast industry demands near-perfect casting quality.

However, even experienced foundries often face various technical challenges. For example, when using vacuum casting machines for production, although the vacuum environment effectively reduces oxidation and porosity issues, problems such as surface porosity and gray residue can still occur due to equipment, materials, process parameters, and other factors. This article will take vacuum casting machines for gold and silver bars as an example, providing a detailed analysis of common issues in the production process and their solutions, aiming to offer systematic technical reference for practitioners.

I. Brief Introduction to the Working Principle of Vacuum Casting Machines

A vacuum casting machine is equipment used for melting and casting metals under vacuum or inert gas protection, widely applied in the forming of high-purity precious metal materials. Its basic workflow includes:

Preheating Stage: Preheat the graphite mold for 1–2 minutes.

Melting Stage: Melt the metal material using medium-frequency induction heating under vacuum or protective atmosphere.

Cooling Stage: After melting, the machine automatically stops heating and begins cooling, also under vacuum or protective atmosphere.

Removal and Post-Processing: After cooling, the product is removed for subsequent steps such as polishing and stamping.

Although the vacuum environment significantly improves ingot purity, product quality issues may still arise due to equipment condition, process parameters, material quality, and other factors.

II. Common Issues and Solutions

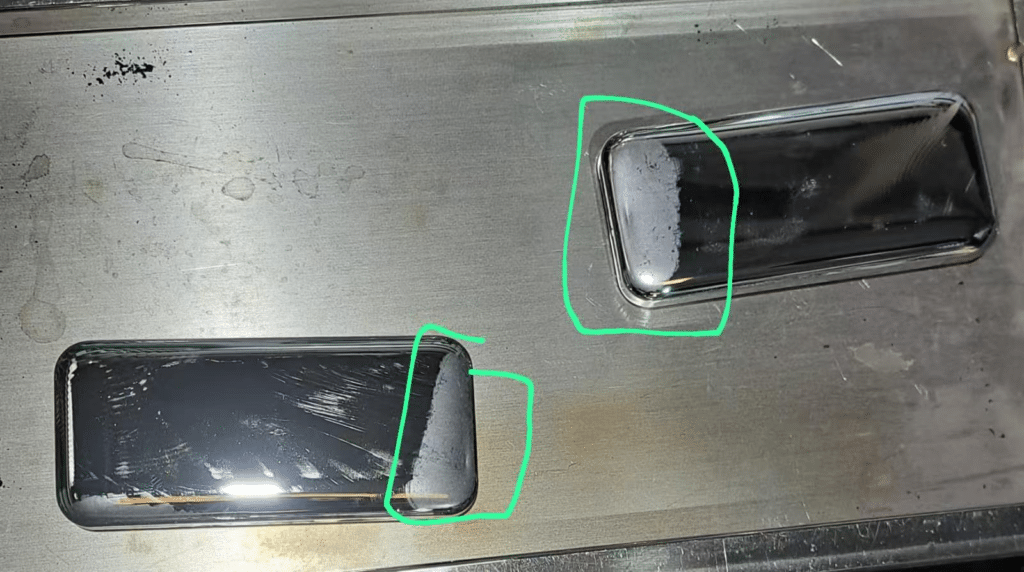

1. Gray Film-Like Substance on the Surface of Gold Bars

As shown in the image below, the silver bar surface appears wrapped in a gray film, feeling stained to the touch, which affects appearance and purity testing. This is actually graphite powder.

① Graphite mold oxidizes or physically wears at high temperatures, causing powder to shed.

② Low-density, porous mold structure prone to powder shedding under high temperature and thermal shock.

③ Excessive preheating time or temperature accelerates graphite oxidation.

Graphite materials come in various grades with different prices, sometimes differing by up to twofold. Customers often ask why our molds are much more expensive than others’. The answer is simple: you get what you pay for!

High-density graphite is relatively more expensive but offers longer service life and less powder shedding. Low-density graphite is cheaper but sheds more powder and has a shorter lifespan. The choice depends on your needs and budget. You can also compare different graphite materials.

Solutions:

① Use high-density graphite molds: It is recommended to use high-purity isostatic graphite with a density ≥1.80 g/cm³, which has a dense structure, good high-temperature resistance, and a long service life.

② Control preheating process: Limit preheating time to 1–2 minutes, stopping before the graphite mold turns red to avoid overheating.

③ Regularly clean molds: Use a soft brush to remove residue from the mold surface every 10–15 batches.

④ Post-processing polishing: For ingots with adhered powder, use a vibratory polishing machine for surface polishing to restore luster.

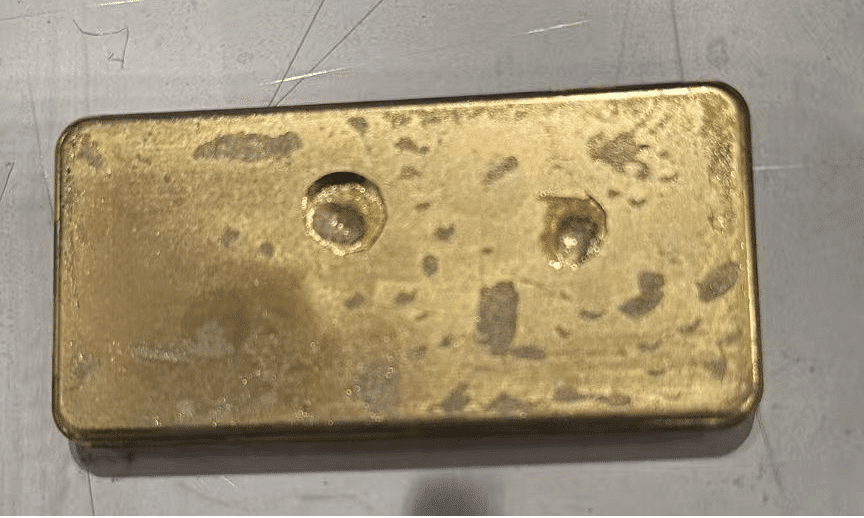

2. Surface Porosity

Pin-like or larger pores appear on the surface of gold bars, caused by insufficient vacuum extraction. First, verify if the vacuum pump specification is suitable, then check if the vacuum pipeline is correctly connected and if there are any air leaks in the machine. If all these are fine, check if the machine’s vacuum extraction time is appropriate.

This is a clear sign of insufficient heating, requiring extended heating time. Different materials need different heating times. For example, granular materials require shorter heating times than lump materials. If the material is mixed (lumps and granules), heating time should also be extended.

① Incomplete cleaning of raw materials, leaving residual pickling or reducing agents (e.g., insufficient washing of sponge gold).

② Raw materials contain non-metallic impurities such as sulfur or phosphorus.

③ Impure materials, possibly containing rhenium or titanium, misrepresented as gold.

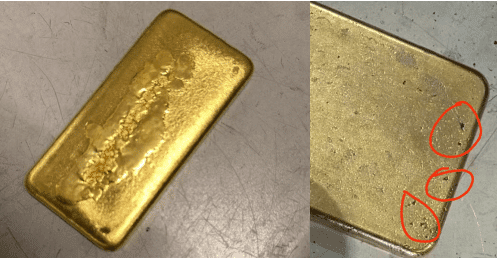

Some clients claim to use 999 purity raw materials, but after casting, the surface shows the issues pictured above.

The left image is caused by incomplete cleaning of refined materials, leaving chemical residues. In wet refining, gold liquid enters the reactor for reduction and precipitation to obtain sponge gold, which must be washed before subsequent melting and casting. The cleaning process involves two steps: acid washing and water washing. First, use nitric acid for acid washing, then use pure or distilled water for water washing, ensuring all chemical agents are completely removed from the sponge gold.

The right image clearly shows small black dots due to excessive non-metallic substances in the gold, affecting surface crystallization. These can be picked out with a sharp needle, and the material can be remelted.

If issues persist, consider replacing the material batch and recasting for comparison.

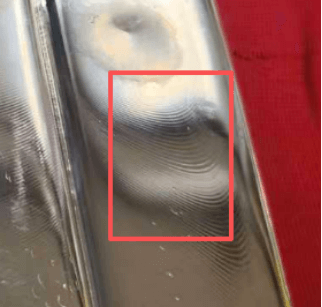

5. Waves and Flow Marks on the Product Surface

This occurs due to slight vibrations during the cooling and forming process, caused by uneven placement of the machine or nearby heavy machinery.

-

Ensure the machine is placed on a stable, clean, low-dust site.

-

Avoid placing the machine in areas with acidic or alkaline corrosive gases.

-

Do not install the machine in areas with severe metal dust to prevent operational failures.

This is caused by moisture inside the machine. After transportation, especially sea freight over long periods, moisture may accumulate inside the machine. Before the first use, open the machine lid and preheat the graphite mold to allow moisture to evaporate.

When restarting the machine after prolonged idle time, perform the same preheating operation. Ensure the machine lid is open to allow moisture escape; otherwise, water may flow directly from the machine interior.

7. Flash or Combustion When Opening the Machine Lid

Flash or popping sounds occur when opening the lid after casting, with local oxidation discoloration on the ingot surface.

Cause Analysis:

① Insufficient cooling time; mold and ingot temperatures are too high, causing rapid oxidation upon contact with air.

② Premature release of the vacuum system, allowing residual oxygen into the melting chamber.

③ Insufficient flow or purity of protective gas.

Generally, cooling time should be longer than heating time, or at least equal. Otherwise, insufficient cooling of the mold can cause combustion upon sudden contact with cold air when opening the lid, posing a safety hazard.

III. Summary

With technological advancements, many high-end casting machines are now equipped with real-time monitoring and intelligent feedback systems, automatically adjusting heating power, cooling rates, and other parameters, significantly improving product consistency. Enterprises with the means are advised to gradually introduce digital control systems to transition from experience-based casting to precision manufacturing.

Casting is a craft that blends materials science, thermodynamics, and artistic technique. Only by pursuing excellence in every detail can we create precious metal products truly worthy of heritage.