- Call Us: 008615168765707

- Mail Us: [email protected]

Buy the most advanced wire annealing furnace in the market, inquiry now!

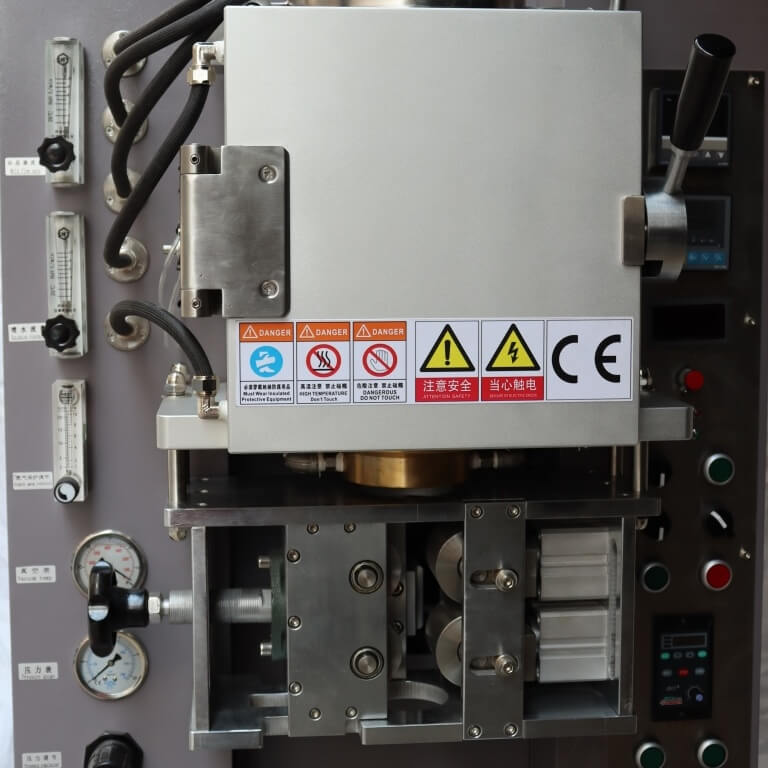

In the field of precious metal processing, CDOCAST wire annealing furnace is an advanced solution specifically designed for annealing fine wires with diameters ranging from 0.03 mm to 2 mm. Ideal for annealing gold, silver, platinum, palladium, and other special alloys, this furnace plays a crucial role in industries such as jewelry manufacturing, electronics, and high-precision engineering.

*1. Precision Heating Process

The furnace utilizes an advanced resistance heating system to achieve a highly uniform temperature distribution. Depending on the material, the annealing temperature can be precisely set—typically 300°C to 600°C for gold and silver, and up to 800°C for platinum and palladium. A user-friendly touchscreen HMI allows operators to program custom temperature profiles based on different wire types and production requirements.

*2. Soaking Stage for Optimized Structure

Upon reaching the target temperature, the system maintains a stable soaking time to ensure complete recrystallization of the metal. This eliminates internal stresses induced during wire drawing or forming, thereby enhancing ductility and structural uniformity.

*3. Rapid Water Cooling System

An integrated water tank enables direct quenching of the annealed wire, facilitating rapid cooling, refining the grain structure, and improving mechanical properties.

*4. Servo-Controlled Wire Tension System

To prevent tangling and ensure smooth processing, servo motors automatically regulate wire tension throughout the annealing and coiling processes. This is particularly critical for ultra-fine wires where consistency is paramount.

*5. Ammonia Dissociation Bright Annealing (Optional)

For applications requiring superior surface finish, an ammonia dissociation unit can be integrated. This system generates a hydrogen-rich atmosphere, reducing surface oxides to produce bright, clean wire free from discoloration or oxidation.

Interested in optimizing your wire annealing process? Contact us today for a solution tailored to your needs!

| Model number | CDO-WA1 |

| Voltage | Single phase 220V, 50/60Hz |

| Power | 6.5kw |

| Heating current | 18A |

| Gas consumption | Nitrogen 2-3L/M |

| Maximum temperature | 1000℃ |

| Application metal | Gold, silver, copper, platinum, etc. |

| Wire diameter | 0.03-2mm |

| Dimension | 2100*850*1830mm |

| Weight | 350KG |

1. An annealing furnace is usually capable of reaching higher temperatures to anneal metal. Depending on the needs of different precious metals, the stripping furnace can be heated to hundreds of degrees Celsius or even 1000°C.

2. The stripping furnace is usually equipped with a high-precision temperature control system to ensure that the temperature in the furnace is maintained within a stable and accurate range. This is crucial for the annealing process, because the physical properties and performance of metals vary significantly at different temperatures, and precise temperature control can ensure the consistency and effectiveness of metal annealing treatments.

3. The CDOCAST stripping furnace is equipped with an automated control system. Users can monitor and adjust parameters such as temperature, time and atmosphere through the touch screen. Automated control not only improves production efficiency, but also reduces errors and safety hazards in manual operations.

4. Modern stripping furnaces are usually designed to be easy-to-maintain structures. The heating elements and atmosphere control systems in the furnace can be easily inspected and replaced to ensure long-term stable operation of the equipment.

1. Q: What metals can this machine process?

A: It can anneal precious metal wires such as gold, silver, copper, platinum, etc.

2. Q: What wire sizes can it anneal?

A: We have currently tested wires ranging from 0.03-2mm.

3. Q: How to adjust the working parameters for different sizes of wire?

A: Basically, only the speed and temperature need to be adjusted. For smaller diameter wires, the annealing speed should be slower. Specific adjustments can be made based on actual production conditions.

4. Q: What type of protective gas can be used? What is the consumption?

A: Argon or nitrogen can be used. Nitrogen consumption is 2-3L/min.

5. Q: How do I make my wires shine?

A: We can add an ammonia decomposition device to break down ammonia into hydrogen and nitrogen. The hydrogen is then reduced, making the wires shine.

6. Q: What is the maximum operating temperature?

A: Our machine’s maximum operating temperature is 1000℃. We can customize higher temperatures if needed, but 1000℃ is generally sufficient.

7. Q: Why is the heating zone angled?

A: The angled design allows the heating element to enter the cooling water, creating a seal and preventing the release of protective gases.

8. Q: How is the heated wire cooled?

A: The machine is equipped with a cooling water tank at the rear. Before operation, add water to the tank (note that the water temperature should not exceed 30℃, and the water must be clean and changed regularly).

9. Q: How do I set the wheel diameter and width in the parameter interface?

A: Before operation, you must install the wheels on the furnace. Measure the wheel diameter and width according to the diagram in the user manual and input them into the parameter interface. Otherwise, the working speed will not be synchronized.

Q: Why doesn’t the wire feeding wheel rotate after the machine starts?

A: You need to click “Drawback” after powering on; otherwise, the wheel rotation will be out of sync, and wire feeding will fail.

Q: What is the production capacity per hour for processing gold?

A: This question cannot be answered directly. Output depends on the wire diameter and annealing speed. For example, for 1mm gold wire, if annealed at a speed of 2m/min, the hourly production capcity can reach 3.6kg (double-tube furnace). In actual production, the annealing speed needs to be adjusted according to the wire diameter; smaller wire diameters require slower annealing speeds.

Q: What’s the dimension of the machine?

A: Dimension: 1980*690*1600mm(L*W*H)

From ultra-fine precious metal wires to a broader range of industrial alloys, CDOCAST wire annealing furnace offers unparalleled flexibility, precision, and ease of operation. With its programmable controls, tension management, and optional bright annealing capabilities, it is the ideal choice for manufacturers pursuing quality, repeatability, and efficiency.

1. Enhanced Ductility and Formability

Annealing restores the metal’s ductility, making it easier to shape, coil, or braid—which is especially important in the production of jewelry and microelectronic components.

2. Elimination of Internal Stresses

By removing stresses caused by cold working, the furnace minimizes the risk of cracking or breakage in fine, delicate wires, thereby improving yield and reliability.

3. Superior Surface Quality

Equipped with optional atmosphere control and rapid cooling, the system prevents oxidation and contamination, delivering a clean, bright finish ready for immediate use.

✔ Jewelry Manufacturing: Annealing gold and silver wires for chains, filigree, and decorative elements.

✔ Electronics & Micro-engineering: Production of bonding wires, lead frames, and conductive components.

✔ Special Alloy Processing: Annealing platinum and palladium wires for sensors, catalysts, and medical devices.

A: It can anneal precious metal wires such as gold, silver, copper, platinum, etc.

A: We have currently tested wires ranging from 0.03-2mm.

A: Basically, only the speed and temperature need to be adjusted. For smaller diameter wires, the annealing speed should be slower. Specific adjustments can be made based on actual production conditions.

A: Argon or nitrogen can be used. Nitrogen consumption is 2-3L/min.

A: We can add an ammonia decomposition device to break down ammonia into hydrogen and nitrogen. The hydrogen is then reduced, making the wires shine.

A: Our machine’s maximum operating temperature is 1000℃. We can customize higher temperatures if needed, but 1000℃ is generally sufficient.

A: The angled design allows the heating element to enter the cooling water, creating a seal and preventing the release of protective gases.

A: The machine is equipped with a cooling water tank at the rear. Before operation, add water to the tank (note that the water temperature should not exceed 30℃, and the water must be clean and changed regularly).

A: Before operation, you must install the wheels on the furnace. Measure the wheel diameter and width according to the diagram in the user manual and input them into the parameter interface. Otherwise, the working speed will not be synchronized.

A: You need to click “Drawback” after powering on; otherwise, the wheel rotation will be out of sync, and wire feeding will fail.

A: This question cannot be answered directly. Output depends on the wire diameter and annealing speed. For example, for 1mm gold wire, if annealed at a speed of 2m/min, the hourly production capcity can reach 3.6kg (double-tube furnace). In actual production, the annealing speed needs to be adjusted according to the wire diameter; smaller wire diameters require slower annealing speeds.

A: Dimension: 1980*690*1600mm(L*W*H)

A: It can anneal precious metal wires such as gold, silver, copper, platinum, etc.

A: We have currently tested wires ranging from 0.03-2mm.

A: Basically, only the speed and temperature need to be adjusted. For smaller diameter wires, the annealing speed should be slower. Specific adjustments can be made based on actual production conditions.

A: Argon or nitrogen can be used. Nitrogen consumption is 2-3L/min.

A: We can add an ammonia decomposition device to break down ammonia into hydrogen and nitrogen. The hydrogen is then reduced, making the wires shine.

A: Our machine’s maximum operating temperature is 1000℃. We can customize higher temperatures if needed, but 1000℃ is generally sufficient.

A: The angled design allows the heating element to enter the cooling water, creating a seal and preventing the release of protective gases.

A: The machine is equipped with a cooling water tank at the rear. Before operation, add water to the tank (note that the water temperature should not exceed 30℃, and the water must be clean and changed regularly).

A: Before operation, you must install the wheels on the furnace. Measure the wheel diameter and width according to the diagram in the user manual and input them into the parameter interface. Otherwise, the working speed will not be synchronized.

A: You need to click “Drawback” after powering on; otherwise, the wheel rotation will be out of sync, and wire feeding will fail.

A: This question cannot be answered directly. Output depends on the wire diameter and annealing speed. For example, for 1mm gold wire, if annealed at a speed of 2m/min, the hourly production capcity can reach 3.6kg (double-tube furnace). In actual production, the annealing speed needs to be adjusted according to the wire diameter; smaller wire diameters require slower annealing speeds.

A: Dimension: 1980*690*1600mm(L*W*H)

CDOCAST Provide 2 Warranty time , and during the warranty time we will be responsible for the all aftersales service & spare parts for free

CDOCAST Provide more value & turnkey Solution to Metal Melting & Casting According to Each Customer

We owe it to each of our customers, CDOCAST adopt world famous brand components to improve our machine working performance.

Inquiry About CDOCAST wire annealing furnace

Contact Our Engineer Team

CDOCAST Jewelry Continuous Casting Machine For making jewelry into wire, rod , plate

How to Make high quality Gold Bar & Bullion -Introduction Of Vacuum gold bar casting machine

Granulating Machine for making gold and silver grains, which can match the Vacuum gold bar casting Machine

Gold Vacuum casting machine is designed for those ingot casting of gold, silve or other precious metal on basis of the customized mould…….