Metal Powder Water Atomization Equipment

Metal Powder Water Atomization Equipment is a kind of powder preparation method in which metal or alloy liquid is broken into small droplets by fast-moving fluid (atomization medium) impact or other ways, followed by condensation into solid powder. Any material that can form a liquid can be atomized and powdered. The high-pressure water atomization method can economically and mass-produce MIM metal alloy powder, special stainless steel powder, high-speed steel powder, precious metal powder, copper-based alloy powder, and super alloy Powder, etc.

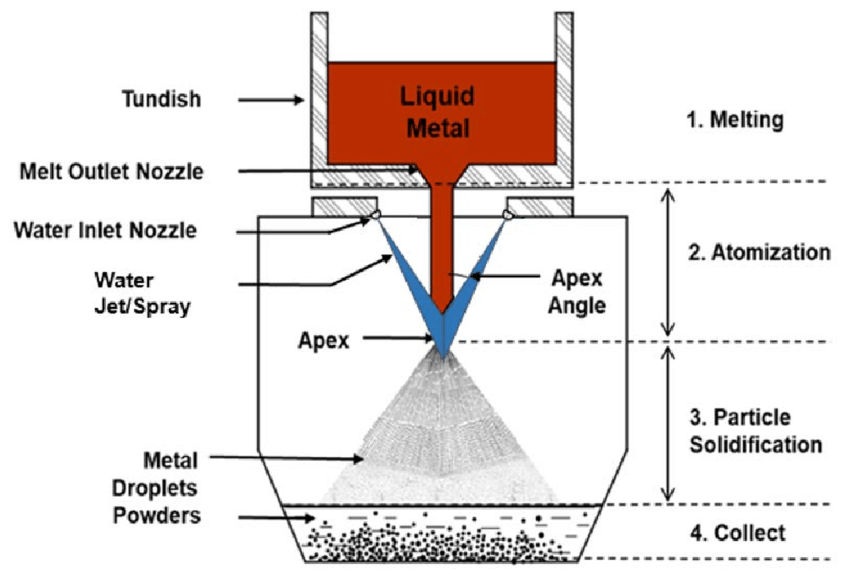

The most widely used are gas atomization Equipment and water atomization Equipment. In the process of atomization powder producing process, melt the metal raw materials into qualified alloy liquid (generally superheated at 100-150 ℃) by an electric furnace or induction furnace, and then injected into the tundish above the atomizing nozzle. The alloy liquid flows out from the leaking hole at the bottom of the tundish, and when it passes through the nozzle, it is atomized into fine droplets when it encounters the high-speed airflow or water flow. The atomized droplets are rapidly solidified into alloy powder in the closed atomizing cylinder. Generally, the inert gas atomized powder particles are round, with low oxygen content (less than 100×10), and can be directly made into densified products by thermoforming technology (such as hot isostatic pressing).

The water atomized powder particles are mostly irregular shapes with high oxygen content (above 600×10) and must be annealed. It has good compressibility and can be cold-pressed into mechanical parts.

In this article, we will introduce the metal powder water atomization equipment in detail.

Working principle:

The process of producing metal powder by water atomization pulverizing milling equipment has a long history. In ancient times, people poured molten iron into water and burst it into fine metal particles, which were used as raw materials for making steel; until now, there are people who pour molten lead directly into water to make lead shots. The water atomization pulverizing method is used to make coarse alloy powder. The process principle is the same as the above-mentioned letting water burst the molten metal, but the crushing efficiency has been greatly improved.

In order to make coarse alloy powder by water atomization pulverizing equipment, the coarse gold should be melted in the furnace first, and the molten gold must be superheated about 50 degrees. Then injected into the tundish. Start the high-pressure water pump before the gold liquid is injected, and let the high-pressure water atomization device start the workpiece. The gold liquid in the tundish passes through the beam and enters the atomizer through the leaking nozzle at the bottom of the package. The atomizer is the key equipment for producing crude gold alloy powder with high pressure water mist. The quality of the atomizer is related to the crushing efficiency of the metal powder. Under the action of high-pressure water from the atomizer, the gold liquid is continuously broken into fine droplets, which fall into the cooling liquid in the device, and rapidly solidify into alloy powder. In the traditional high-pressure water atomization process for producing metal powder, the metal powder can be continuously collected, but a small amount of metal powder will be lost with the atomized water. For high-pressure water atomization, the atomized product is concentrated in the atomization device, precipitated, filtered, (if necessary, it can be dried, usually directly sent to the next process.) to obtain fine Alloy powder, there will be no loss of alloy powder in the whole process.

A complete set of metal powder water atomization equipment consists of the following parts:

Melting part: You can choose an intermediate frequency metal smelting furnace or a high-frequency metal smelting furnace. The capacity of the furnace depends on the processing volume of the metal powder. You can choose a 50 kg furnace or a 20 kg furnace.

Atomization part: This part of the equipment is non-standard equipment, which should be designed and arranged according to the site conditions of the manufacturer, mainly including the tundish: when the tundish is produced in winter, it needs to be pre-heated; Atomizer: The atomizer impacts the high-pressure water from the high-pressure water pump at a predetermined speed and angle against the gold liquid from the tundish, breaking it into metal droplets. Under the same pump pressure, the amount of fine metal powder after atomization is related to the atomization efficiency of the atomizer; atomization cylinder: it is the place where the alloy powder is atomized, crushed, cooled and collected. In order to prevent the superfine alloy powder from losing with water, the prepared alloy powder should be allowed to stand for a period of time after atomization pulverizing, and then placed in the powder receiving box.

Post-processing part: powder collection box: used for the collection of atomized alloy powder, separation and removal of excess water; drying furnace: drying the wet alloy powder with water; screening machine: screening the alloy powder, The coarser alloy powder that does not meet the specifications can be used as remelting material to be re-melted and atomized.

The ultra-high pressure metal powder water atomization equipment has the following characteristics:

- It can be used for most metals and alloy powders, and the production cost is low.

- It can prepare subspherical powder or irregular powder.

- Due to rapid solidification and no segregation, many special alloy powders can be prepared.

- The powder particle size can reach a required range by adjusting the appropriate process.

The structure of ultra-high pressure metal powder water atomization equipment

The structure of the ultra-high-pressure water atomization pulverizing (granulation) device consists of the following parts:

Smelting, tundish system, atomization system, inert gas protection system, ultra-high pressure water system, cooling water system, PLC control system, platform system, etc.

Melting and tundish system: In fact, it is a multi-functional induction melting furnace. It consists of a shell, an induction coil, a temperature measuring device, a furnace tilting device, and a tundish. The shell is a frame structure, made of carbon steel and stainless steel, with an induction coil installed in the middle, and a crucible inside the induction coil, which can be smelted and poured. The tundish is installed on the nozzle system to store molten metal liquid and has a heat preservation effect. It is smaller than the crucible of the melting system. The tundish holding furnace has its own heating system and temperature measurement system. The heating system of the holding furnace has two methods: resistance heating and induction heating. The resistance heating temperature can generally reach 900℃, and the induction heating temperature can reach 1200℃ or higher, but the crucible material should be selected reasonably.

Atomization system: The atomization pulverizing system consists of nozzles, high-pressure water pipes, valves, etc.

Inert gas protection system: In the process of powder making, in order to reduce the oxidation of metals and alloys and reduce the oxygen content of the powder, a certain amount of inert gas is usually introduced into the atomization tower for atmosphere protection.

Ultra-high-pressure water system: This system is a device that provides high-pressure water for the atomizing nozzle. It consists of a high-pressure water pump, a water tank, a valve, a high-pressure hose, and a busbar.

Cooling system: The whole set of equipment is equipped with water cooling which is indispensable. The temperature of the cooling water will be reflected on the secondary instrument to ensure the safe operation of the device.

Control system: The control system is the operation control center of the device. All operations and related data are transmitted to the PLC of the system, and the results are processed, saved and displayed through calculations.

Features:

Small feeding volume, can obtain imitated spherical, high-loose ratio, low oxygen content powder or irregular shape, low loose ratio, low oxygen content powder.

Application fields:

Research and development of colleges and universities, research institutes for metal powder; gold, silver, platinum and other precious metal powder.

The video of metal powder water atomization equipment

Click to watch the video of atomization pulverizing equipment→