Metal Granulating machine For Gold Silver Copper Graining Making

CDOCAST Metal Granulating machine

Metal Granulating machine is a kind of machine for making various metal grains such as gold, silver, and copper, it is widely used in the fields of jewelry and refinery.

Cdocast has launched some different models of granulators, which are suitable for various metals, and various capacities, to meet the needs of different customers. Let me introduce for you

1. Small Metal Granulation tank

If you have a melting furnace, you can consider buying only a granulation tank, this is the simplest model, melting and granulation are carried out on different equipment. It mainly consists of a stainless steel tank, water pump, and gas fire gun. The operation is easy, just use a small induction furnace to melt the metal and then pour the liquid metal into the graphite crucible on the granulation tank to make grains. Kindly note: we need to heat the crucible on the granulation tank which can prevent the metal from cooling down and plugs the holes in the bottom of crucible, usually this small Granualting tank we will suggest a capacity from 1kg-5kg.

2:Small metal granules Casting machine

This Metal Granulating machine is integrated type granules-making machine which has the function of melting and granulation. It’s suitable for making 1 or 2 kg of gold, silver, and copper grains. It mainly consists of the water tank, graphite crucible, thermocouple, operation panel, and power supply. After finish melting, the molten metal will flow down to make granules. This small granulator is very suitable for small refineries and Jewelers

3:4-12 KG Gold Silver Copper Granulating Machine

This Model Metal Granulating machine is designed for making 4-12 kg gold, silver, and copper grains. It looks similar to the last model, but with one very big difference: it’s equipped with a protective gas device, which proves uniform granules, stable color, and no bubbles. And it comes with a lid of the melting chamber to prevent liquid spillage. The integrated design can reduce the cable connection between too many power cabinets and granulation parts, and reduce many unnecessary safety hazards. This 4-12kg granulator is the best-selling machine sold by CDOCAST. It is very popular with customers because it is affordable, simple, and convenient, The 24-hour continuous working capacity ensures that even this granulating machine comes with max 12kg grains-making capacity , can also meet the production needs of most customers

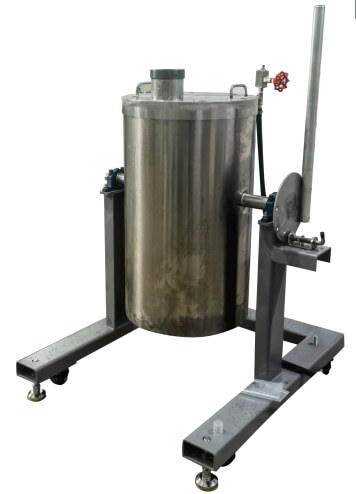

4:20-50 kg granulator with graphite plug

This Metal Granulating machine is designed with a capacity of 20-50 kg. Compared to the above models, this model looks more sophisticated and has a more complex structure. It has a graphite plug on the top of the melting chamber. When starting the melting, move the graphite plug to block the crucible hole. After finish melting, press the side switch, and lift the graphite plug, and the liquid metal will flow down and start granulation. Besides, it has equips with a heightened stainless steel water tank and automatic loading tray. Install the loading tray and press the side switch, the loading tray will automatically lift, which is more convenient. Because of the large melting capacity of this granulator, there must be a large enough water tank (The water tank designed by us is at least 1m height))to avoid the water temperature rise and metal particles Sticking to each other caused by long-time grains making, With the increase of Grains making capacity, it is also necessary to consider whether the operation of workers is convenient. Therefore, we have designed an additional automatic loading tray lifting, thus, There is no need to manually lift the material Tray filled with metal particles, which provides great convenience for workers’ operation

5:20-50 kg granules-making machine with automatic stirring system

This model Metal Granulating machine is also designed for 20-50 kg gold, but it equips with an automatic stirring system. On the machine body, there is a speed controller to control the stirrer. High-speed stirring can accelerate melting and after melting finish, rotate the roller to lift the stirring device and start granulation. This Metal Granulator is specially designed for Making Metal Alloy granules When customers manufacture alloy particles, they need to have a stirring system, which can stir the molten metal during melting, making the molten metal more uniform and the particles produced more uniform The motor drives the mixing Graphite Graphite rod, and the mixing speed can be adjusted according to client requirement, The material of the stirring rod can be graphite or boron nitride, and the corresponding material can be selected according to the different needs of customers

6. Vacuum metal granules making machine

The vacuum Metal Granulating machine adopts the vacuum pump to ensure that the entire granulation process is under the vacuum condition which can minimize oxidation, it is suitable for some metals that easily oxidize. The operation panel is a Siemens touch screen. You just need to set the parameters and the machine will work automatically. The Vacuum metal granules making machine melting Capacity range from 6kg-50kg with the latest induction Technology, The vacuum pump of German quality ensures that the granulation is in a high vacuum environment, so the quality of metal particles obtained is higher When making some special alloy particles, Like K Gold, which need to be granulated under vacuum condition. The vacuum environment can ensure that the metal is not oxidized and can obtain brighter and more rounded metal particles. Due to the complex structure and high production cost of vacuum metal granulator, their price is higher than that of ordinary granulator, so it is more suitable for some large enterprises or special industries

7. Platform-type metal granules-making machine

Platform type Metal Granulating machine is specially designed for making large capacity metal granules such as 50kg, 100kg, and 150kg, etc. It’s suitable for gold, silver, and copper as well as high-temperature metal such as steel, iron, etc. It includes a platform, hydraulic tilting melting furnace, granules-making machine, and water chiller. The Hydraulic Tilting melting Furnace is used for melting metal from 50kg-300kg within 30 mins, The tundish must be continuously heated to ensure that the molten metal will not cool down and block the granulation hole in the Granulating Crucible. an independent heating system will be adopted to heat the tundish, The specially designed granulation lower cylinder is large enough to ensure that the metal particles will not stick under continuous operation for a long time。 Each set of large granulators is equipped with a material loading Tray and a water tank, the loading tray is used for receiving metal Grains, and the water tank is used for cooling and replacing the water in the lower cylinder that is heated up due to long-time granulation. This granulator can continuously produce for 24 hours to meet the needs of mass production, max batch capacity can reach 300kg per batch

That’s all the models of our Metal Granulating machine, if you want to know more details, warmly welcome your inquiry!